The Magpie Wants a Lot - Longer Ray5 20 Watt Laser Test

Bitang is strong, the price is quite bearable in comparison.

contents show

Introductory

Those who know me know that I've been using lasers quite a bit for a while now. I have been able to try several machines, I have traveled the path of war from 2,5 watt heads to 10 watt ones. Those in the know will already know from this that I'm basically talking about blue laser machines, CO is still Chinese to me. So, if you think in the direction of CO, then this article is not for you.

Unfortunately, blue laser machines, if they do not even represent the CO category in terms of price, are quite expensive. Small, 2,5 watt solutions are affordable, and 5-5,5 watts is slowly falling below the pain threshold for many. 10 watts still indicates a semi-professional level, 20 watts is almost the ceiling, because this year 1-2 manufacturers came out with 33 watt heads. Well, that's already at a CO level price.

So I do business with 10 watt machines, I like them, they are suitable for what I need. But, sometimes they are slow. It happens that I have to produce more than one workpiece, and in this case speed is very important. The end result will still be beautiful, I think many COs would only blink at what can be obtained from these machines, which are basically manufactured for hobby purposes.

Well, 20 watts is something. They are also quite expensive, but I heard that the 20 watt blue laser is already close to the level of the smaller CO lasers. Anyone familiar with the subject knows that although CO is strong and all, it requires much more care than blue laser solutions. That is why the latter have spread to home use.

So, if someone has a 20 watt blue laser, it's almost CO level, but with a lot less macera. And it costs a lot.

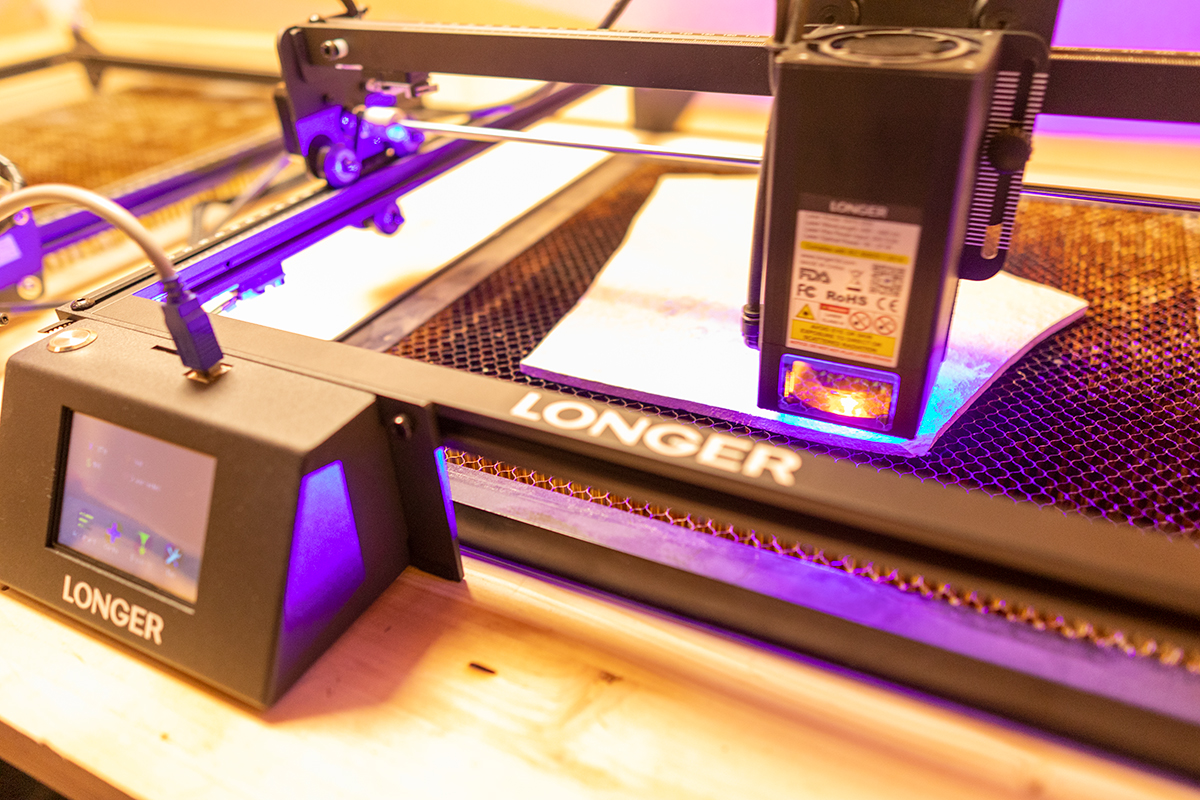

I wrote this so that you can understand why I "shouted" a big YES into Skype when one of my partners asked me if I wanted to try the Longer Ray5 engraving machine 20 WATTS!!!! head. Well, I wouldn't have wanted to try it in the storm, when I never had such a powerful laser, and I won't have it for a long time!

Unpacking, assembly, accessories

I don't want to spend a lot of time on the assembly itself. That is, by describing how to assemble it. The manufacturer has provided a professional video for this, in which everything is perfectly visible, and there is nothing more I can do about it. But in short, the point is:

The Longer Ray5 is a typical, simple unit for home use. It has to be assembled from the usual aluminum elements and the usual fastening elements have to be used, so whoever put together such a machine will be able to put it all together (with a slight exaggeration).

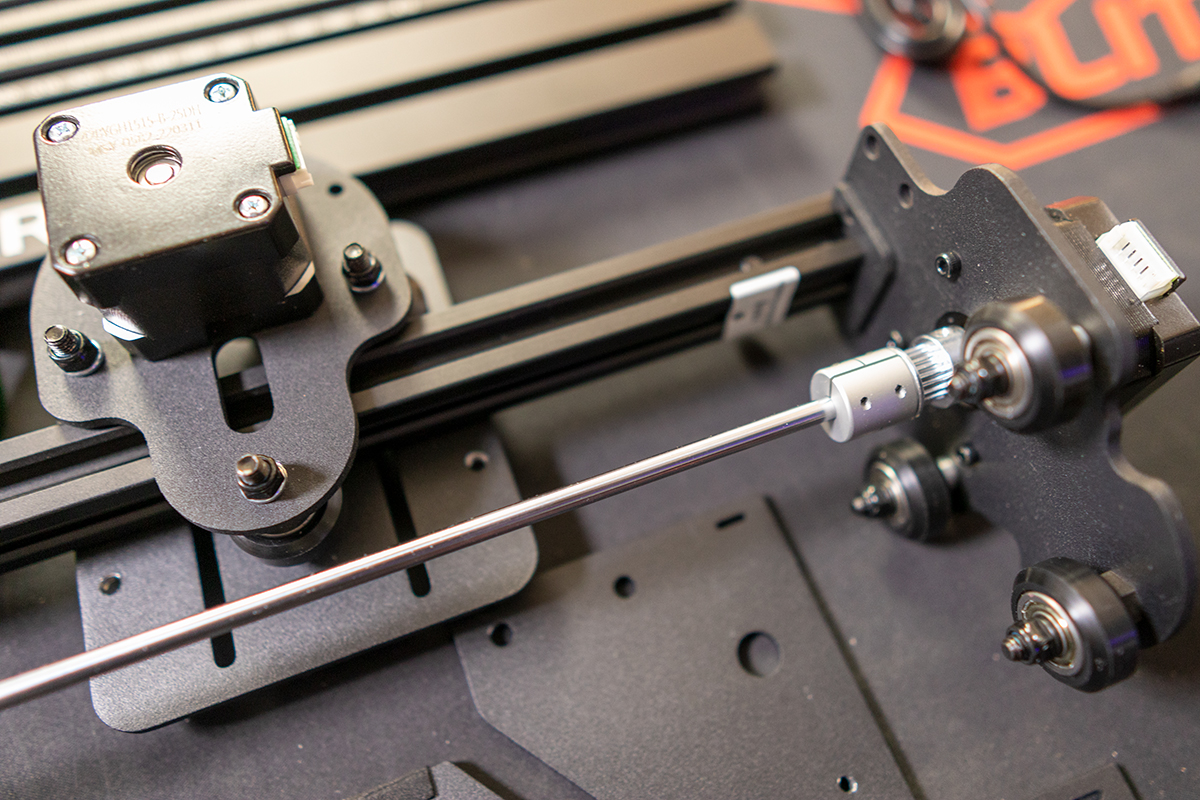

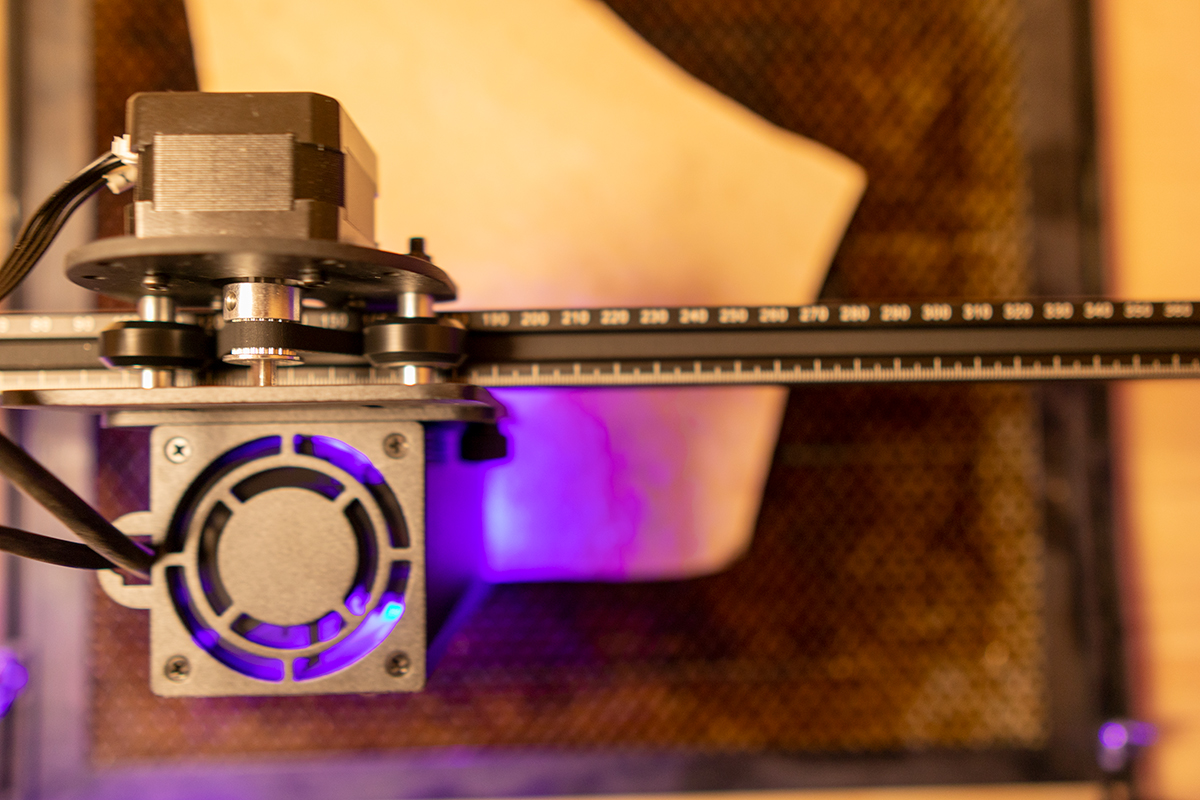

The installation is really not complicated anyway. We fasten the long rails in a square shape, place (string) the rail of the X axis on the rail of the Y axis, screw on the display, the legs, put the ribbed belts in place, screw on the limit switches, connect the cables and that's it. Yes, it is enough to put the laser unit in its place, because without it the whole thing is worthless. Well, we're done now!

There are not many accessories, that is, there are many, but not more than in the case of an average laser. We get tools for assembly, we get a small amount of test material and we also get glasses. Don't forget, because it's important, an AirAssist pump is included with the 20-watt laser, you'll need it, but I'll write about it later.

So the bottom line is that I recommend watching the manufacturer's video. This will also be good for getting to know each other, that is, to see what the machine is like and, if applicable, to help you make a decision if you are considering buying it.

Paper form

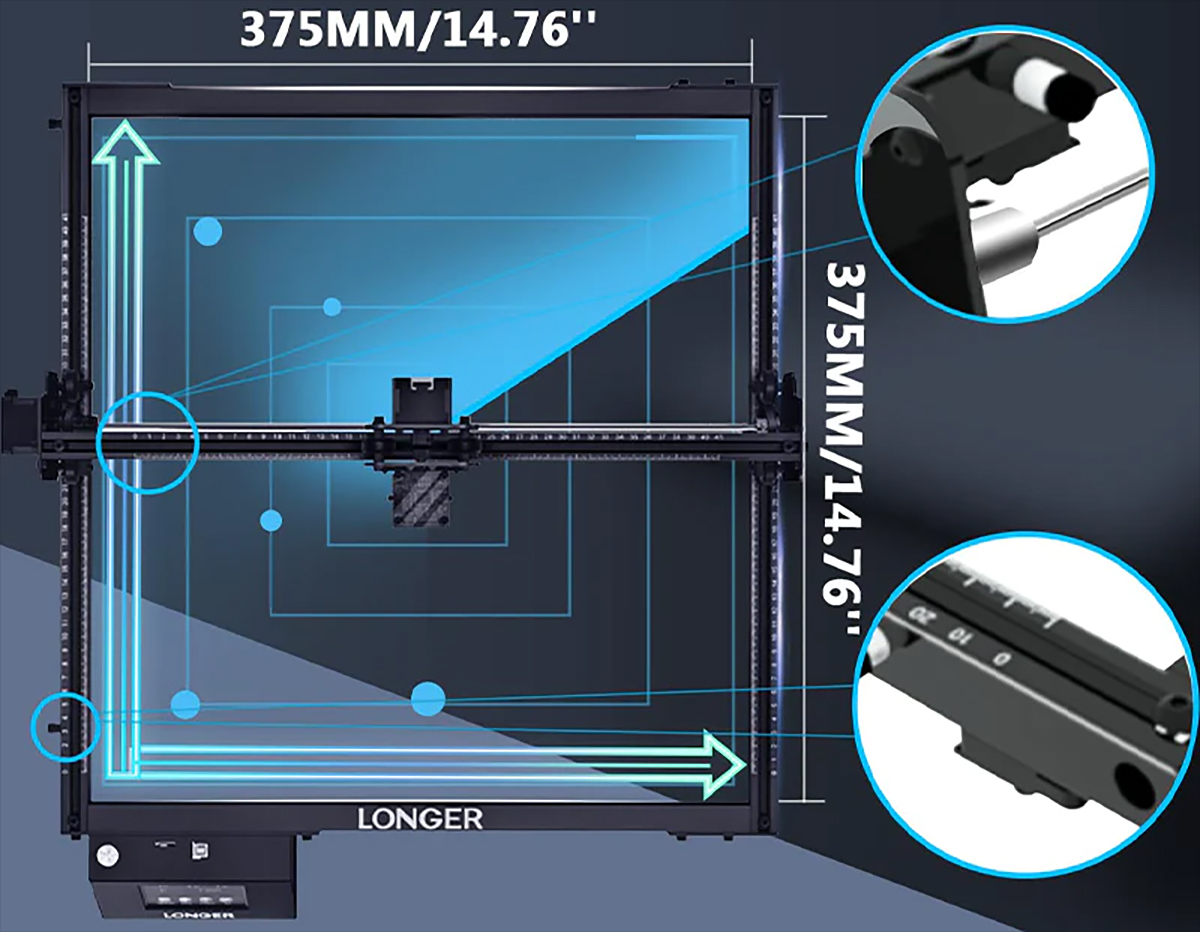

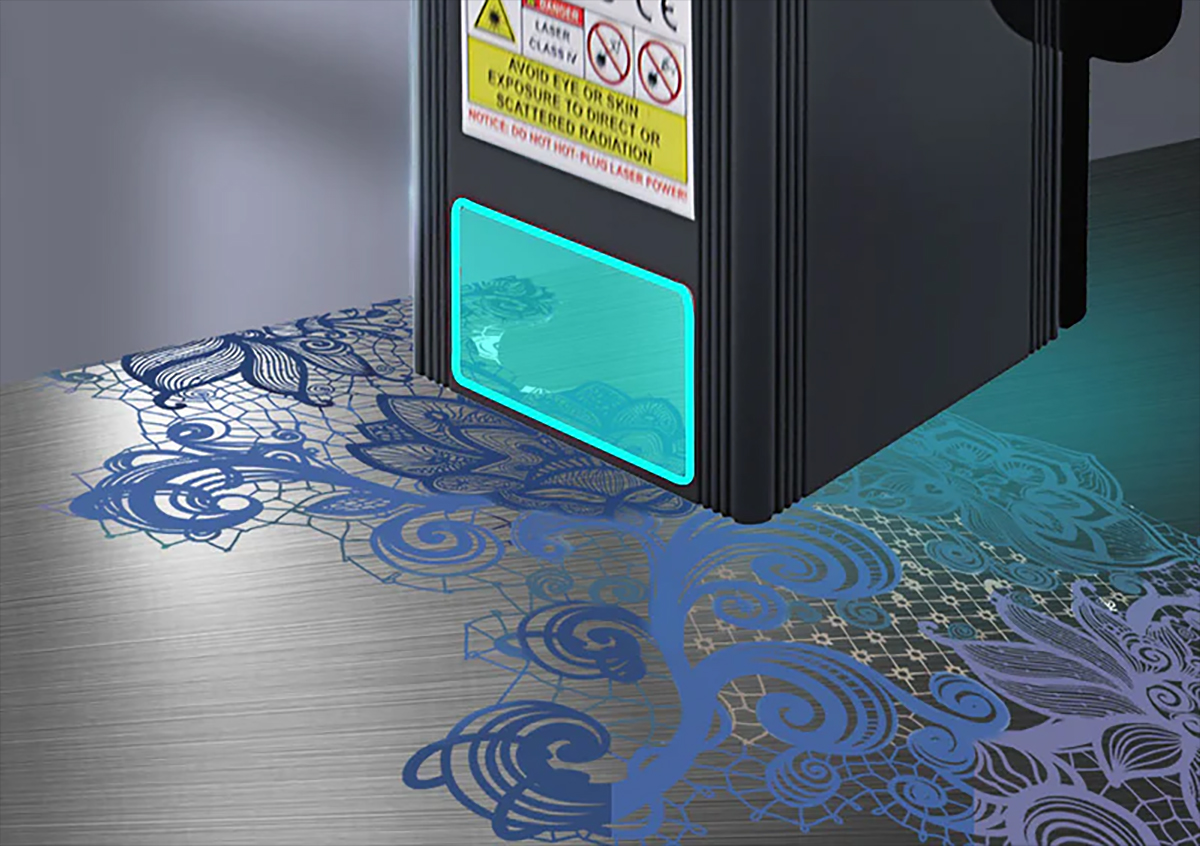

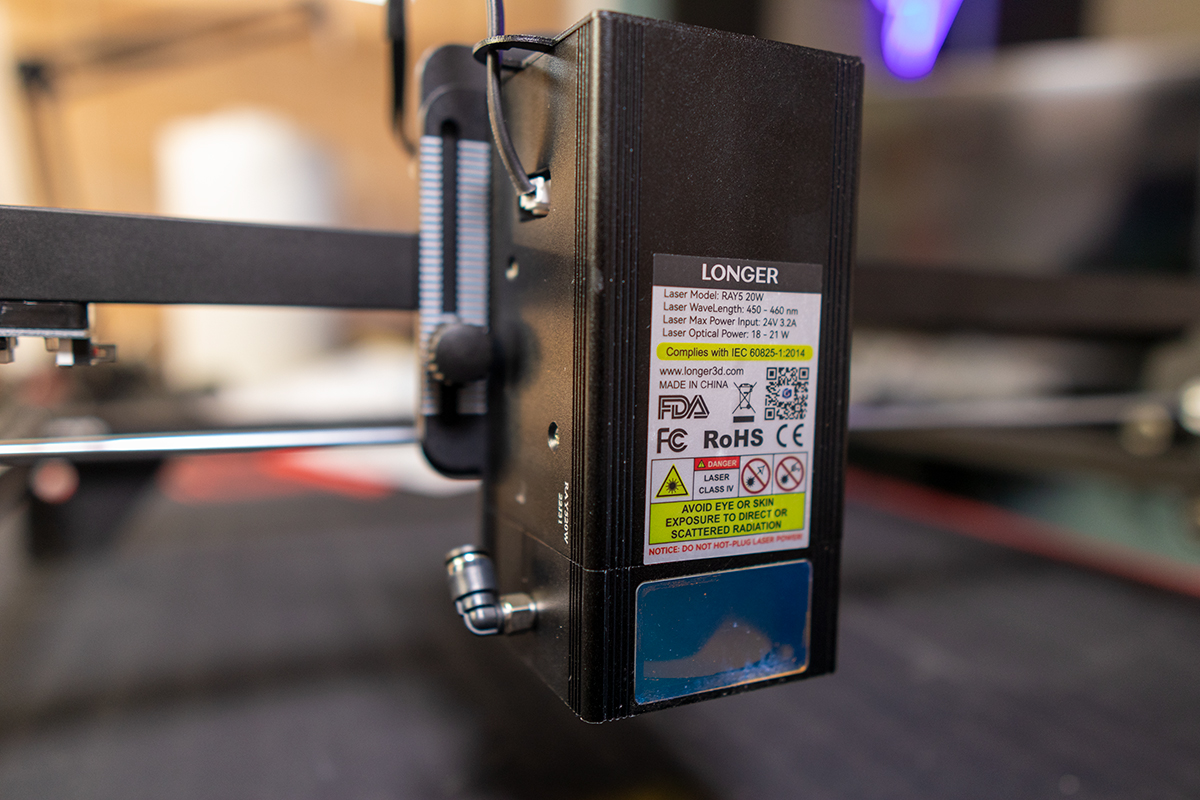

The Longer RAY5 20W laser engraver is a state-of-the-art machine that offers powerful cutting, high-precision laser engraving and cutting, and multi-color engraving capabilities with its four diode lasers. This machine is equipped with X and Y-axis limit switches and 5 safety protections for safer use, and as an extra, it has a 3,5-inch built-in color touch screen that supports offline work and multiple data transfer solutions.

The RAY5 20W laser engraver features a 20W optical output power laser module that uses an advanced optical system to increase cutting capacity. This machine can cut 15mm pine wood and 8mm acrylic in one pass, 25mm wood and 35mm acrylic in multiple passes, and can cut 0,05mm stainless steel. In addition, the laser has a focus of 0,08 x 0,1 mm², which allows thinner lines and clearer textures to be engraved, resulting in finer and more beautiful creations.

The RAY5 20W laser engraver is designed to work efficiently with its powerful laser output power and 120W electrical power. This allows for deeper cuts and speeds up engraving at the same time, saving you a lot of time. One of the exciting features of the machine is the multi-color engraving capability. The 20 W high-energy laser beam immediately oxidizes the metal surface, resulting in rich colors.

For safer use, the RAY5 20W laser engraver is equipped with XY-axis limit switches and 5 safety protections. The emergency stop of the laser is activated if it detects tilting, flame, interruption of the data connection and jamming or jamming of the laser head for more than 15 seconds. In addition, the panoramic filter glass effectively filters the laser and protects the eyes.

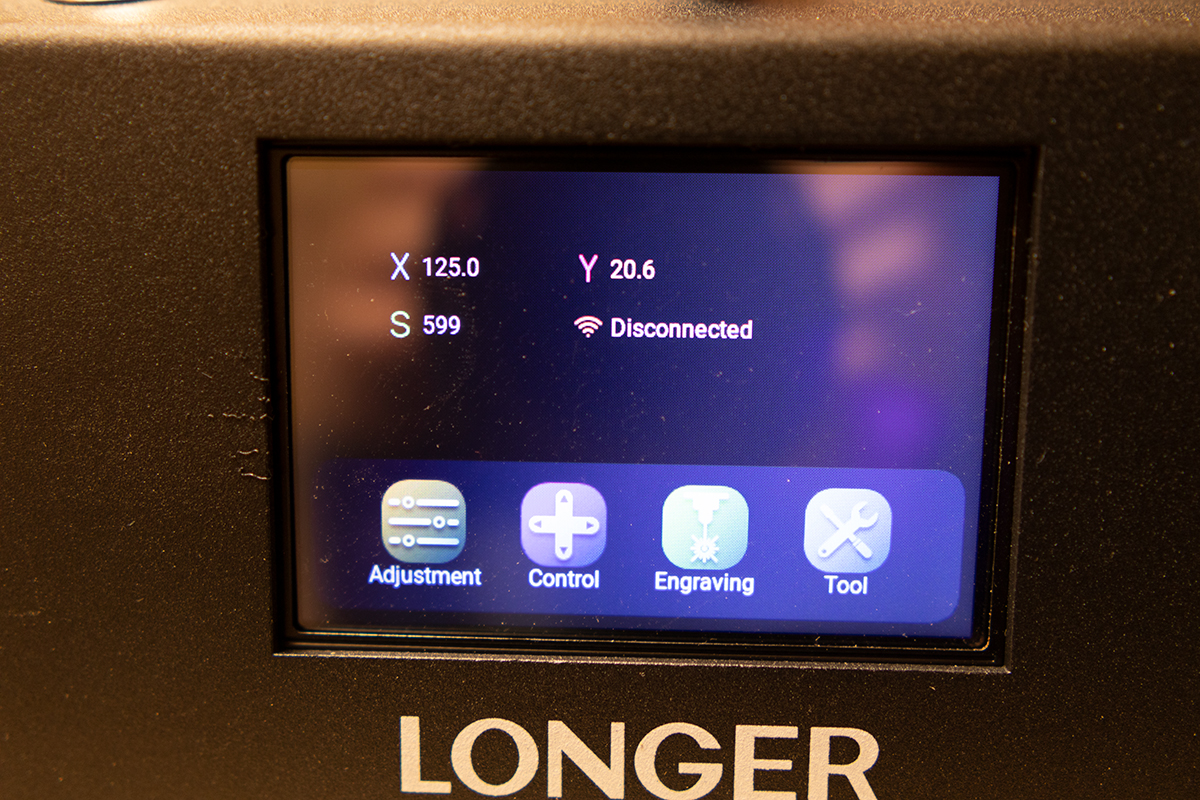

RAY5 20W laser engraver offers multiple data transmission methods including Wi-Fi, USB cable, phone APP and TF cards to support offline operations. You can use RAY5 without a physical connection to a computer. The machine is compatible with various mature engraving software such as LaserGRBL, LightBurn, and supports Windows 7 or newer Microsoft, macOS and Linux. File formats that can be used include JPG, PNG, BMP, G-code, GIF, SVG, NC, GC, etc. formats.

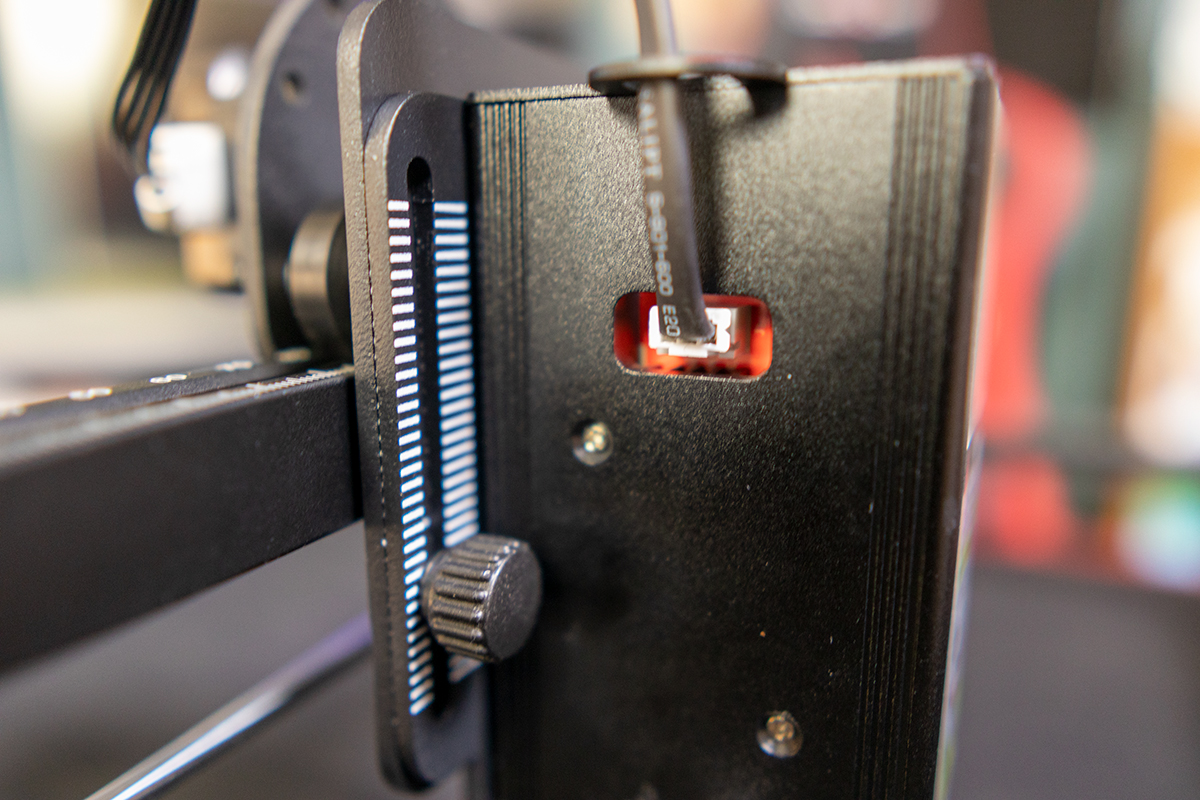

The RAY5 20W laser engraver has a 3,5-inch intelligent built-in color screen, so it is easy to use without connecting the laser engraving equipment to a computer. It supports offline operation and has an easy-to-use focus plate. The laser module also has a 1 mm graduation scale, which allows you to precisely adjust the focus distance according to the thickness of the material used for engraving and cutting. The RAY5 20W laser engraver is built with an ESP32 chipset that runs at a frequency of 240 MHz, making it faster and more powerful than similarly equipped machines with 8-bit chipsets.

Experiences

Well, I have to report quite a lot of things, which can be scary at first, if someone is not familiar with the subject, so I will try to describe clearly that this machine, no matter how powerful it is, is only a home machine and highly recommended for hobby purposes.

Let's start by saying that the Longer Ray5 is not a modern machine. We can still buy it now with a 5-watt or 10-watt laser, as well as this 20-watt one. In other words, the currently available 20-watt device is an upgraded version of the original with lower power.

The fact that it raises a lot of questions in me raises how it is possible that the original machine can handle the 20-watt head without any modifications or second power supply. Of course, you don't have to think anything bad, it's possible that this was the plan from the beginning, so the power supply and the controller were already sized so that the upgrade would be easy.

However, it should not be overlooked that despite this, this is still a wildly new construction, despite the fact that, for example, we have a color touch-sensitive display (which is a very cool thing anyway), and there is also a WIFI connection and a phone application. The fact is that only really modern home machines have these capabilities, so Ray5's competitors are just starting to catch up.

As I wrote above, assembly was simple. I found one thing very strange, the limit switches on the X and Y axes. The installation is a bit random (they are only held by one screw each, I have no idea what will prevent them from turning on that one screw if they feel like it. The other is that the microswitch's metal pin is not clicked through by a metal part of the frame. It touches the rubber roller in a completely incomprehensible way. It is certain that it will not be possible to adjust it with an accuracy of one hundredth of a millimeter. It is needless to say, but even then the solution is strange.

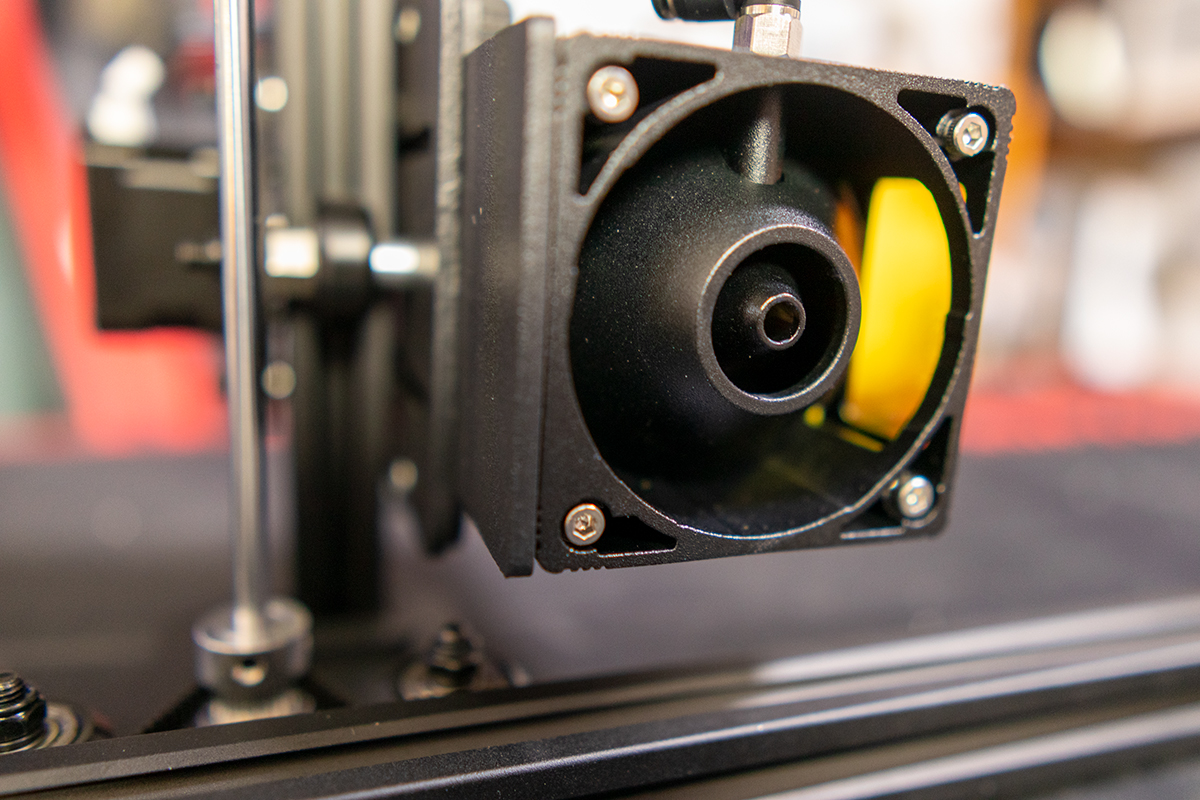

What I really didn't like was the handling of the laser unit. According to the description, as I wrote above, it has an "easy-to-use focus plate". In practice, this means that a 1 cm thick acrylic plate must be placed on the workpiece (under the head), the laser head must be lowered onto it, and then the screws on both sides must be tightened.

Essentially, this acrylic plate is what they call a focus plate, and it's what allows the laser to be aligned perpendicular to the material at all. Because if we try to adjust the head without it, it is almost impossible to achieve the vertical position with the screws on both sides. There is a nut behind the head that guides the head, and there are also two fixing screws, but they are of no use. If I tighten the screw, it tightens, if I release it, it wobbles, if I release it too much, it hits the back plate of the head holder.

It's true that we're good at using acrylic sheet, but as an experienced laserist, I can tell you that it's not a life insurance, because what if the plywood you want to work on is a little warped? If you place the acrylic sheet on the deformed laminate and let the head rest on it, it will not be straight at all. So they could have worked on it a little more.

These are unpleasant things, but one thing I really didn't like was the design of the bottom of the laser unit. I'll try to explain clearly what's wrong with it.

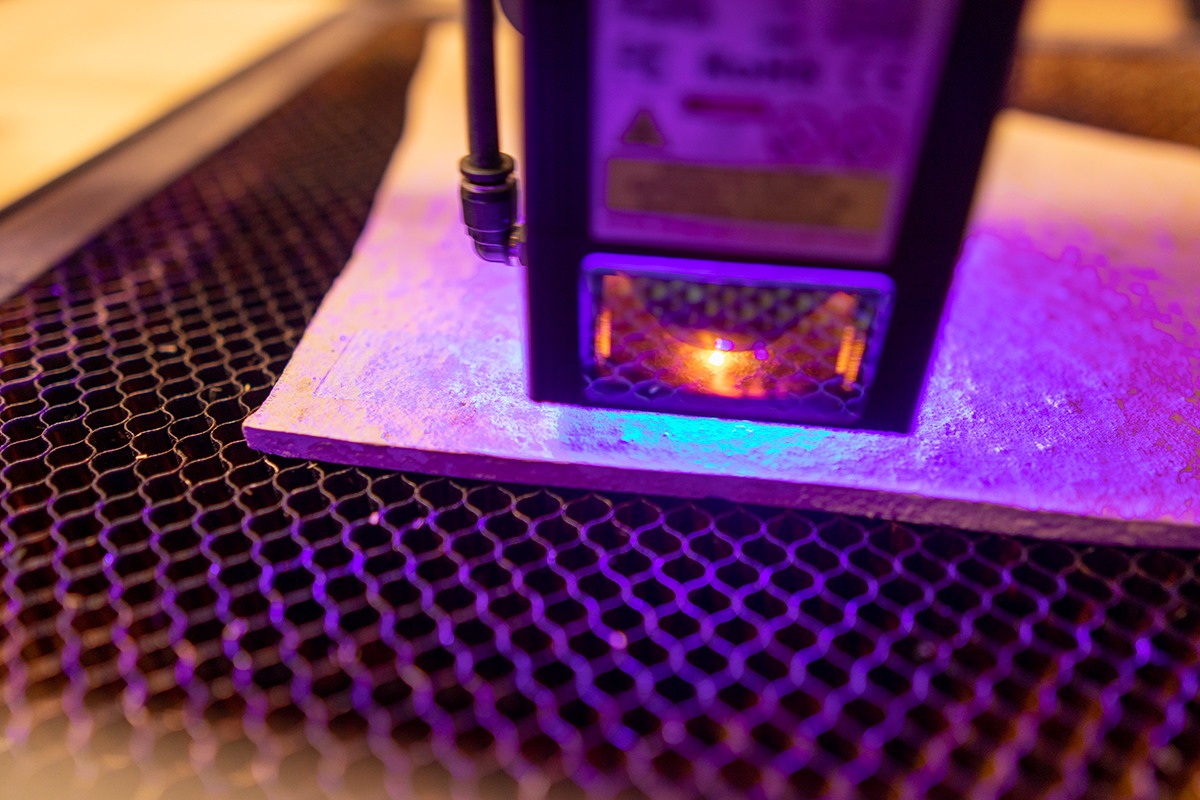

When I position the workpiece under the laser, I use the light of the laser itself to do this. There is a function in the program (LaserGRBL) where the laser turns on with extremely low power and I can see where the focal point is on the material. In such cases, I direct the head to the extreme points of the pattern to be engraved or cut, turn on the laser for a moment, and check that:

- I can work with the smallest possible loss of material,

- Nowhere does the pattern hang off the workpiece or hang together with another pattern,

- If I cut in the first pass and engrave in the second, I can check that the pattern to be cut and the pattern to be engraved overlap.

Well, that doesn't work on this machine. The laser head is very close to the material, so I can only see the point where the laser light reaches the workpiece through the small glass window of the head. This window, on the other hand, is tinted glass to protect my eyes, so I can only see the small dot of the laser on the material. I do not see.

I have a built-in light in the engraving cabinet, which also has the exhaust, so that I can see properly. If I turn on the light, it's good because I can see the workpiece through the darkened glass, but I can't see the laser dot. So, from scratch, as they say.

This is a problem because if I have a lot of workpieces, I can count on a lot of material loss if I can't position the workpiece exactly to within a tenth of a millimeter.

One more thing that I'm going to list as bad, but I promise I'll finish it afterwards!

I tried multi-color engraving on steel, but for God's sake it wouldn't work. I understand the principle, if we heat steel, then (perhaps because of the carbon in it, but please correct me if not) the material changes color to different degrees due to different amounts of heat. There can be blue, green and all kinds of shades, of course no one should look for, say, pink or lemon yellow, the method cannot handle that much.

However, I didn't really like this colorful engraving. There were colors here and there, but I didn't make a single work that I want to present now, to demonstrate the advantages of color printing.

The bad things have lasted until now, now the good ones can come!

Let's start with the software stuff!

The display as previously tested Longer LK4X 3D printerit worked here as well. It's very convenient to be able to set the parameters on the touch-sensitive display, and the pictograms are also nice, so that's fine. Another issue is that I did not make use of the capabilities, but not only this, but also the memory card data entry, there is a simple reason for this.

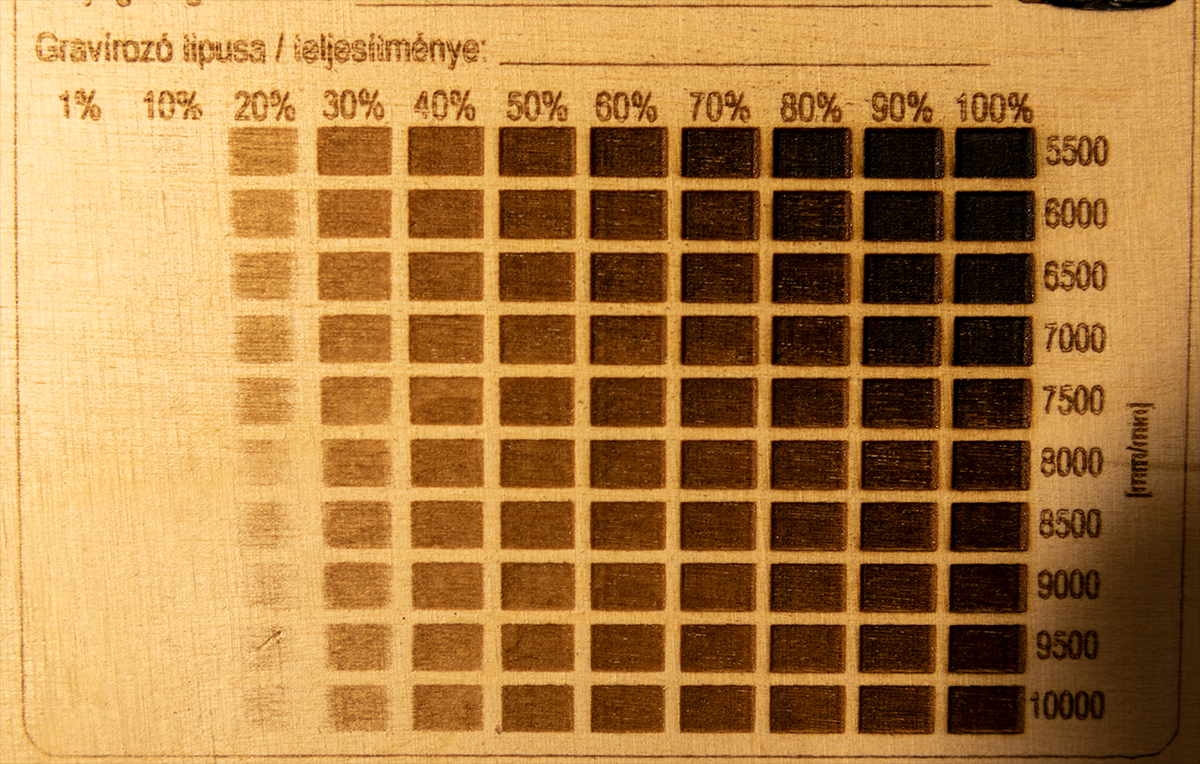

Test engraving with different carriage speeds and laser power. In the case of the darker cubes, the light strip on the right is not the fault of the engraving, at those speeds and strengths the laser has already deeply burned the square into the material, the edge of this burning is visible.

As you can see, at a speed of 10 millimeters/minute, we can still create very beautiful shades. Naturally, I set the dynamic laser power for engraving, and set the usable range to 000-0%.

In the case of the 3D printer, I dared to leave the machine there while I was working, because printing from a memory card is particularly useful there. In the case of the laser, on the other hand, don't think of leaving the machine unattended, and if you are right next to it, everything can be done from the computer. The settings, as well as the "tailoring pattern", everything can be done from the computer, so the display and the card reader become a bit pointless (but not superfluous).

Here, it is important to note that these are findings based on my habits and work, it may be that the work with the memory card and the display will be evident for you!

As I wrote, there is a WiFi connection and there is also a phone application. As I already wrote about a previous engraver, these are good things, but for me they are completely unnecessary things. But that doesn't mean you will either. The program is good, easy to use, everything makes sense, and if you want to start smaller tasks, such as sending a photo directly from the phone to the engraver is perfect for such tasks. It's really just a personal social problem that I don't have such tasks, so I don't make use of this otherwise great skill.

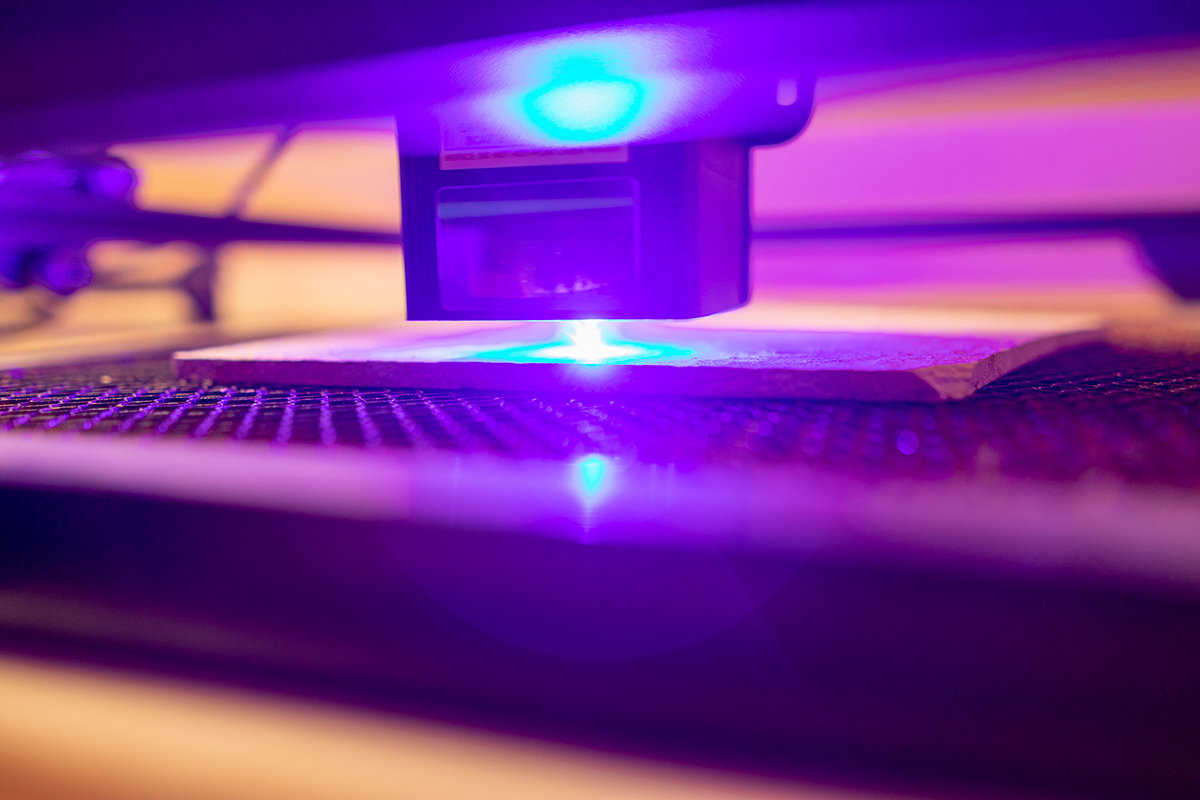

So far so good, but how is the hardware itself? Well folks, 20 watts is a hell of a lot. Imagine this by buying 4 5,5 watt lasers, using prisms and lenses to focus their light into a single point, this is how the max. 21 watts of optical output power. The remainder is the loss due to the optical system.

Even with 5,5 watts, you can cut 3-4 millimeter plywood quite nicely, now imagine what 20 watts can do! He carried the eight-millimeter plate like butter in one go. It's true, I had to reduce the speed properly, to about 150-170 millimeters, but even then, it's something really great.

If you haven't cut with such a machine yet, I'll tell you why it's so good! That's because no matter how much air you use, if you have to go through a piece of wood in several passes in order to cut it, the material will burn. It is not always at the bottom or top, often inside, within the material, which makes the cut not straight, but concave. That is, it bends inwards, towards the interior of the material. This does not happen in one go if you have set the speed well.

An added advantage is that we can save an inordinate amount of time when cutting, if you don't have to go through 2-3-4-5-6-7-8 any number of passes to cut through the material. This is an amazing advantage compared to weaker lasers!

Not only does it cut plywood super well, it also cuts smooth spruce like butter. I cut about 2 cm of material with it. No burning, no inflammation, nothing. The material was barely sooty when cut, the stuff is simply great.

Of course, I tried engraving on metal and stone, and everything was good on these materials as well. It's true, it wasn't better than 10 watts, but it was much faster.

Another thing worth highlighting, and in my opinion a super big advantage, is that the head wears out much faster when using the maximum power of the blue laser. For this reason, it makes sense to cut back a bit on performance, rather to cut in several passes, even if it takes more time. Well, in the case of 20 watts, the subdued laser power is also brutal, so you not only save time with it, but you can also significantly increase the lifetime of the laser unit.

To be honest, I haven't gotten very far with engraving. In other words, I engrave very nicely with it, there is nothing wrong with that, but I have not yet found the settings that will make the quality good and the speed as fast as possible. When engraving, many things can be regulated, which all change the quality of the end result. The strength of the laser, the speed of the car, whether it draws the pattern back there or always only from one direction, what the level of detail should be, what graphic settings to use for jpg or png files, and I could go on and on.

With a relatively low car speed and a very low laser power, I was already successful (you can see this, for example, in the first picture of the article), but with this laser, the main thing would be to be able to achieve a quality similar to that created with a weaker laser at the highest possible speed, of course much faster.

I mentioned above that I will write more about AirAssit. Well, now is the time!

The manufacturer will give us an AirAssist pump for free, as a gift, next to the machine. That's great, we save a lot of money. Let's say the pump is quite interesting, because neither the amount of air can be regulated, nor can it be turned off. This is not a problem for me, my machines are also on a switchable distributor, and the pump belonging to the machine is also plugged into the distributor to which the machine is plugged, so if I connect the machine to electricity, I also turn on the pump and vice versa.

But, if you don't want to use it this way (I recommend this solution anyway, because it's safe if you disconnect the power after work), it will be a bit of a pain to have to unplug and plug in the pump separately. And it is guaranteed that you will forget to plug it in before cutting and start working without air.

The pump itself works very well anyway, the amount of air passing through it corresponds to 20 watts. Not more, but as much as you need. It's not too loud either, and because of its rubber soles, the vibration doesn't transfer to other objects either, so it's perfectly usable anyway.

And, what is important, it must be used. Even weaker lasers are able to burn the material without blowing in extra air, but 20 watts, as I have written several times, is indeed 20 watts. hard as a lightsaber, burns like the worst. This requires AirAssist, because without it you will burn everything badly while cutting.

Of course, engraving is a different matter, the quality of the work there depends on whether you use air or not. It is optional, the wood will have a different shade as a result of the engraving.

Summary

Let's start with why the title of the article became what it is. I have a bit of a feeling with this machine that the manufacturer wanted to grip too big and then got too little. In other words, the laser unit itself is brutally good, brutally powerful, it's really a pleasure to use, but only if you don't think about the fact that you might start thinking about some kind of business when you buy the machine.

Because the situation is that the 20 watt laser can already be suitable for producing a small number of commercial products with good quality and relatively quickly. This fact is also confirmed by the price, which in our case is 800 dollars, or approx. HUF 275 thousand. Don't think that the machine is expensive, it is a very good price for a 20-watt machine, especially if we consider that they also give an AirAssist pump as a gift.

My opinion is that this machine is perfect for working at home, making Christmas decorations for the family, cutting out 3D or simple puzzles for the child, making a gift box or anything else you can think of. In fact, it's not just perfect, maybe a little too much.

I usually say that the laser is not too strong, start with smaller jobs and then you will grow into it. It's not like motorcycling, where it's worth slowly moving up the categories. It's true, a stronger laser is also more dangerous, it's easier to burn through the table, so you have to be smart and treat it with care.

So the point is:

The Longer Ray5 is a powerful machine, but its flaws make it unsuitable for serious work or use in a small business. This is a painful thing, because anyway the strength of the laser is wonderful, amazing, or it doesn't matter how I say it. Don't fall for things like color engraving and cutting through hair-thin sheet steel, there's a good chance you'll never try it, and there's a good chance it's unnecessary.

But it will be good for everything else. You can engrave wood, plywood, leather, glass, stone, steel and anything else you can think of. You can cut many kinds of materials, from cardboard to fabric to different wood materials, and you can make wonderful things at home.

If you like to create, you like to make your own things, and this kind of work gives you joy, then you will love this machine.

The store will automatically put the gift pump in the basket next to the machine, at a cost of HUF 0, of course. The site calculated the shipping cost for me to Budapest at 0 dollars, I think this will be true for the whole of Hungary.

You can order from here (In regions outside the EU, such as the UK and Switzerland, additional customs duties may apply upon receipt.):