Laser engraver from the future - Wainlux K8 test

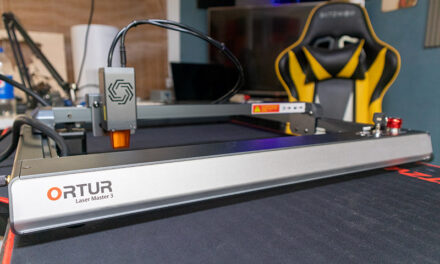

Many people flirt with the idea of making small ornaments, toys, and Christmas tree decorations themselves at home. However, laser cutters/engravers do not seem like a simple tool. Wainlux engineers wanted to create a machine that everyone could use. Let's see how it works!

contents show

Check out my video presentation of the machine!

Laser engraving or cutting seems like a complicated operation at first, and even more complicated the second time, in the end it turns out that if someone really wants to create beautiful things, it will certainly require persistence and a thorough knowledge of a vector graphics program. Of course, it can be simpler than that, for example, we can eliminate the graphics program if we buy ready-made designs on the Internet that we can cut out or engrave.

Even if we do this, we cannot avoid learning the cutting software, we will need to know the materials we are working with, and also to be able to adjust our laser properly so that the work is beautiful and accurate.

All in all, it can be said that above a very beginner level, we will need a lot of learning so that beautiful works come out of our hands.

However, we are not even close to the end of the tasks here, because laser cutting involves a lot of smoke and quite offensive smells. In short, this means that if you want to cut, you have to build a complete exhaust system, the smoke generated during cutting will be taken out of your apartment or workshop.

Of course, there are boxes for this purpose, in which you can put your machine, you get an extractor and a pipe for these boxes, this simplifies the problem a bit. But, in this case, your neighbor is still there, who e.g. in the case of a panel house, it is not certain that Te wants to let smoke in through his window when he ventilates.

There's enough trouble!

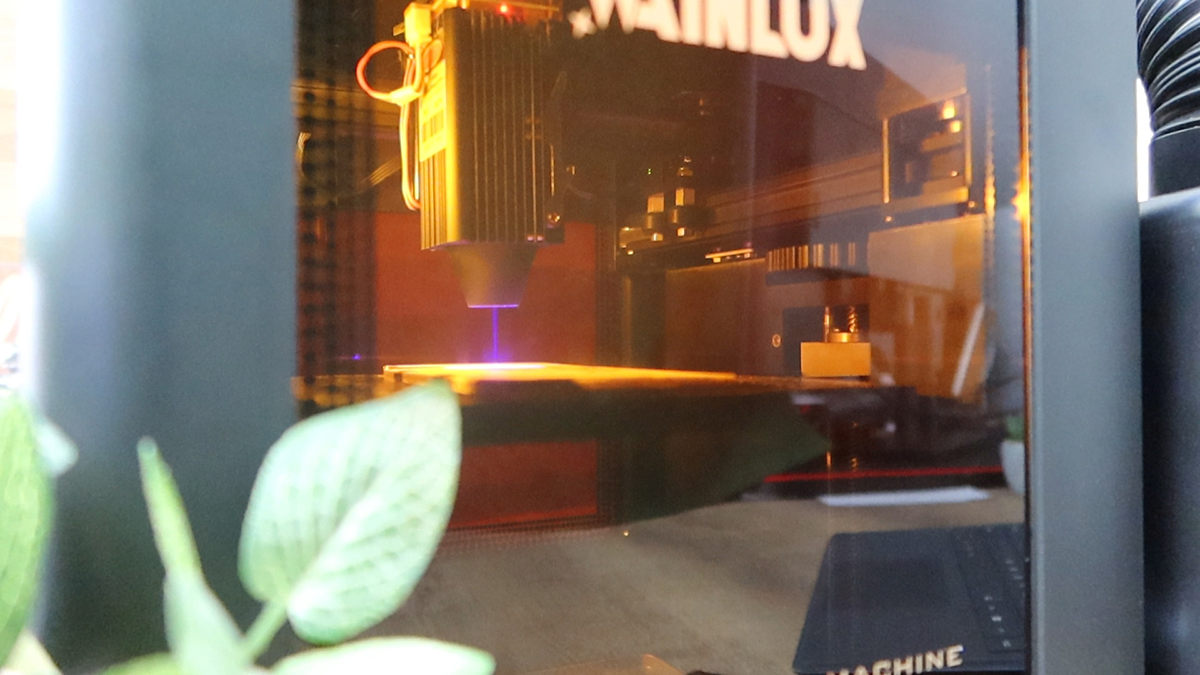

Wainlux set itself the goal of creating a machine that solves and eliminates all these problems, and this is the K8 laser engraver!

The task was not a small one, since we had to create a machine that could be used by beginners without difficulty, we had to create a software that did not require a lot of prior training, and last but not least, we had to do something with the smoke. All in all, this seems like a very demanding and trying task, and it is, by the way.

Wainlux was completely unknown to me until now, and I didn't even know that there was a Kickstarter campaign to raise money for the development of the machine. I didn't know anything about the machine either, but luckily they sent me a promo video, after watching it there was no question that I would accept the job. I was very curious to see how the machine that looks so good in the video turned out to be in reality, and also that it is really as easy to handle as it is presented.

Of course, I will tell you all about them, but now let's finally see the machine!

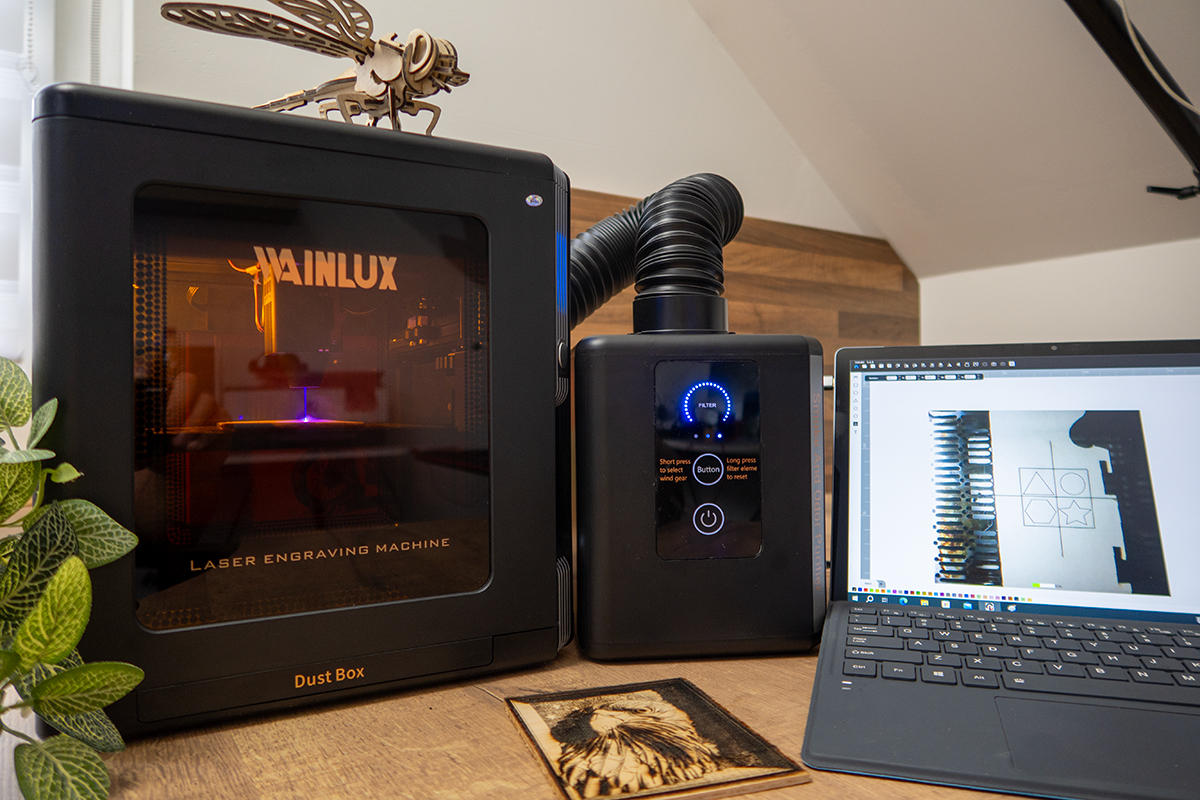

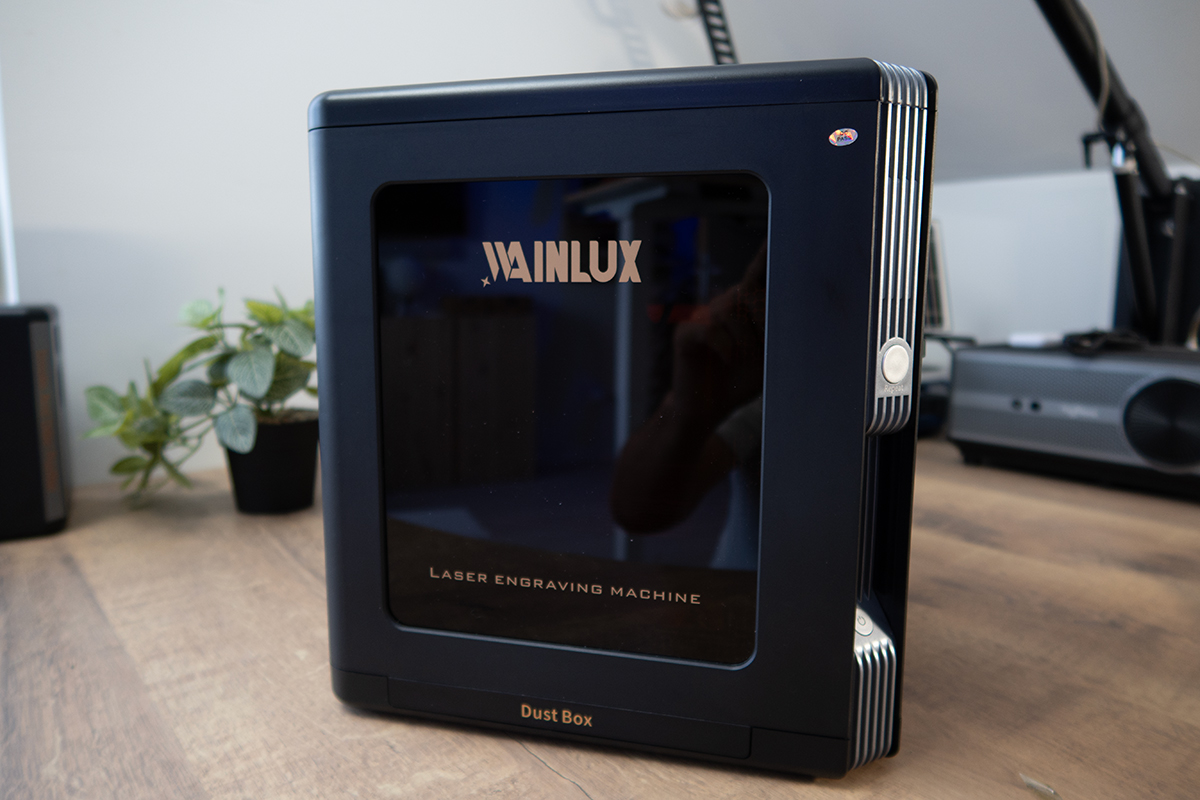

The packaging is perfect, flashy, but not loud, so it definitely inspires confidence. I received two boxes, one containing the K8 engraver itself, the other containing the extractor, which is optional, meaning we have to buy it separately.

The first and most important thing about the machine is that we don't have to install anything. All you have to do is unpack it, plug in the power supply cable, connect it to your computer with a USB cable (Type-C), install the software and start working.

The nice thing about it is that this is happening so far, just as it is promised, that is, the Wanilux K8 essentially just needs to be turned on and it works!

This is exactly the case with the extractor. We also get a power supply for that, we get a laryngeal tube, and the extractor itself. The throat tube is connected to the engraver, the power supply is plugged into the socket, and it can be turned on. No magic, no fun, pretending, rigging. You turn it on and use it. That's it!

Along with the engraver, we also get accessories. Of these, perhaps everyone will like the package in which test materials were packed, because here you have everything from textiles to scratch paper and stickers to plywood, but they also give you two small dog bones, i.e. anodized aluminum whistles, which can be used as collars for dogs. to attach.

There's a little brush, a cleaner to clean the burnt parts, there's an L-shaped magnetic thing (I'll tell you what it is later), and of course we also get a very cultured user manual. Correct package for sure!

Okay, then let's see the machine and the manufacturer's data!

The casing of the machine is ABS, its shape is almost a perfect cube, its height is 30 centimeters, width and length are 27 centimeters each. It has a magnetic door on the front and back, and the doors are made of Plexiglas, which filters the light, so glasses are not even included with the machine. It is important to remember that the work can only be started with the doors closed, so the protection of our eyes is guaranteed!

Seen from the front, there is the power button on the right front corner, a repeat button (as the name suggests, we can use it to repeat the current work process) and an indicator light on top, which shows that the machine is switched on or that work is in progress, not that we wouldn't see this anyway, but safety doesn't hurt.

As you can see, the USB connector and the power connector are on the left rear corner. An important part will also be on the right-hand side panel, here is the connector for the suction throat tube and there is also a fairly large horizontally positioned rotating wheel.

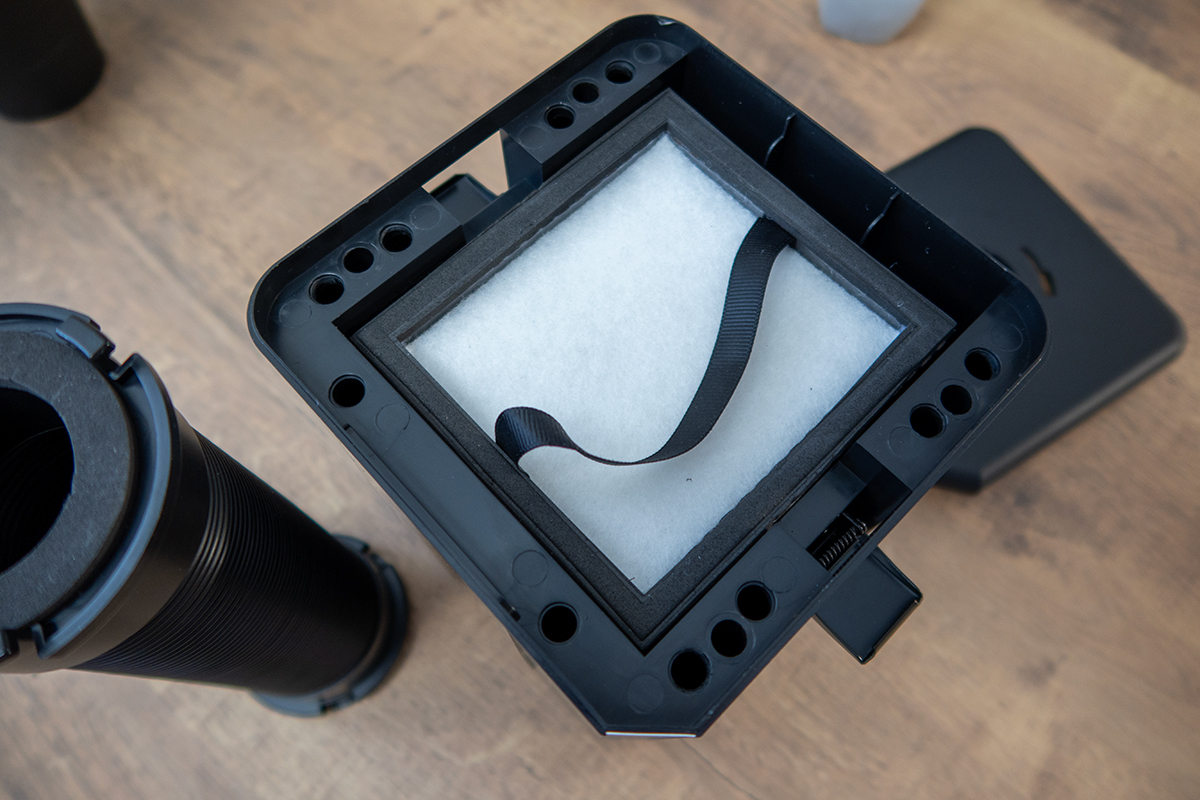

It is important that the manufacturer also considered the possibility of cleaning the fan on the side of the machine, under the throat tube. The lid can be snapped off, the fan can be popped out, it will be worth cleaning with a small brush from time to time.

The K8 can be ordered with three types of lasers, with a power of 2,5, 5, and 10 watts, respectively, the absorbed power is 48, 48, and 60 watts. The maximum size of the workpiece can be 130 x 130 millimeters, and the maximum cutting thickness depends on how powerful the machine is. Anyway, I received a 5-watt one.

The focus of the laser is adequate, 0,08 millimetres, and fine work can be done with it. The focal length is fixed at 40 millimeters. The laser is 455 nanometers long, and according to the manufacturer, it has a lifetime of 27 hours at a temperature of 10 degrees.

We also get data on the engraving speed, depending on the output, they are 7000-12-0000 millimeters per minute, but it is important to note here that these are the recommended maximums, because the setting we need to use depends on the material. In the case of the 15 watt head, e.g. the value of 000 can essentially only be used on paper, the result will not be satisfactory there either.

Two very important features are left out, one is that there is a 2 megapixel camera on the upper part of the engraver's box, above the work piece, and what is even more important is that there is Wi-Fi in addition to the USB connection!

The manufacturer does not provide any relevant data regarding the extractor, so for example we do not get a value for the noise or the air transport capacity either. It would be nice, but practice will show how efficient the machine is anyway.

What we do know is that its size is 19 x 15 x 15 centimeters, and its material is also ABS. The larynx is connected to it on the roof, and the display and controls are located in front. We have an indicator that shows the status of the filter, there are three LEDs that are the level indicator and there is a button that can be used to turn it off or on, and to adjust the strength of the suction, as you can guess, in three levels.

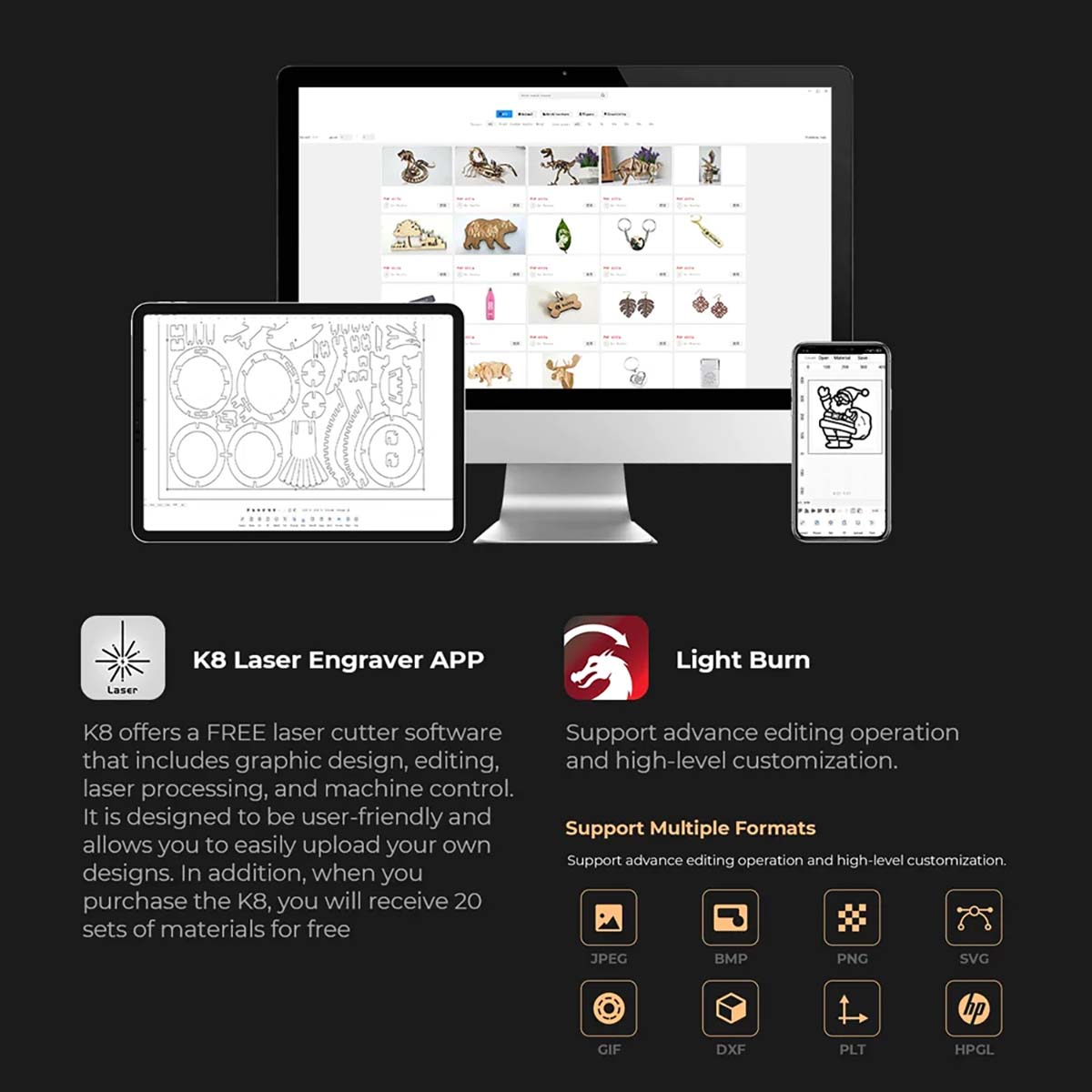

Of course, the Wainlux K8 also comes with software. The machine also works with LightBurn and LaserGRBL software, but I don't want to talk about them, because in order to take advantage of all the capabilities, you need the manufacturer's software, and this is the software that was designed so that even beginners can handle it.

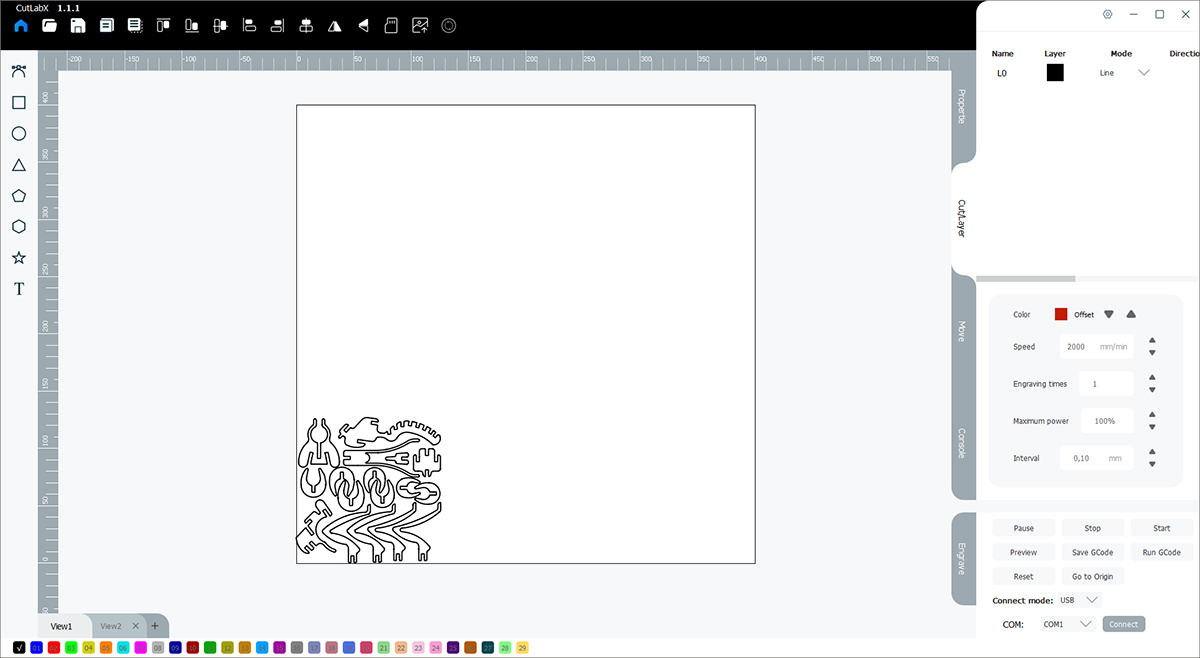

The program is called CutlabX. I will not discuss the installation, it is completely simple, those who have already installed a program under Windows will get by with it.

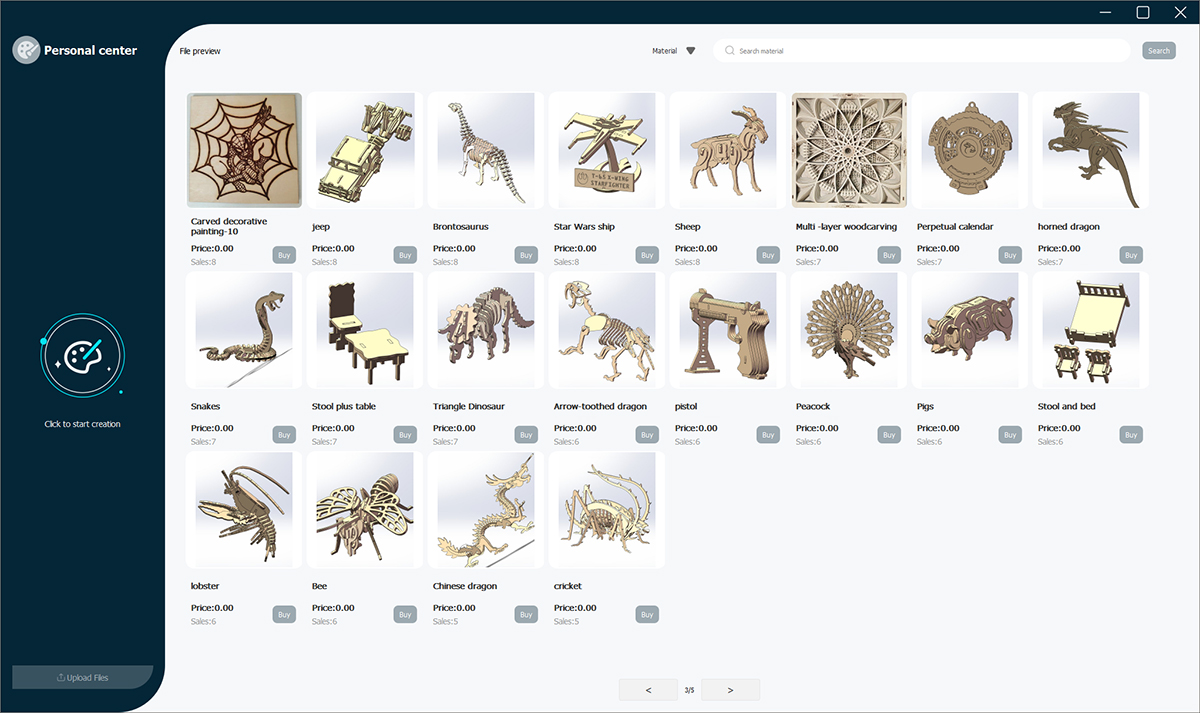

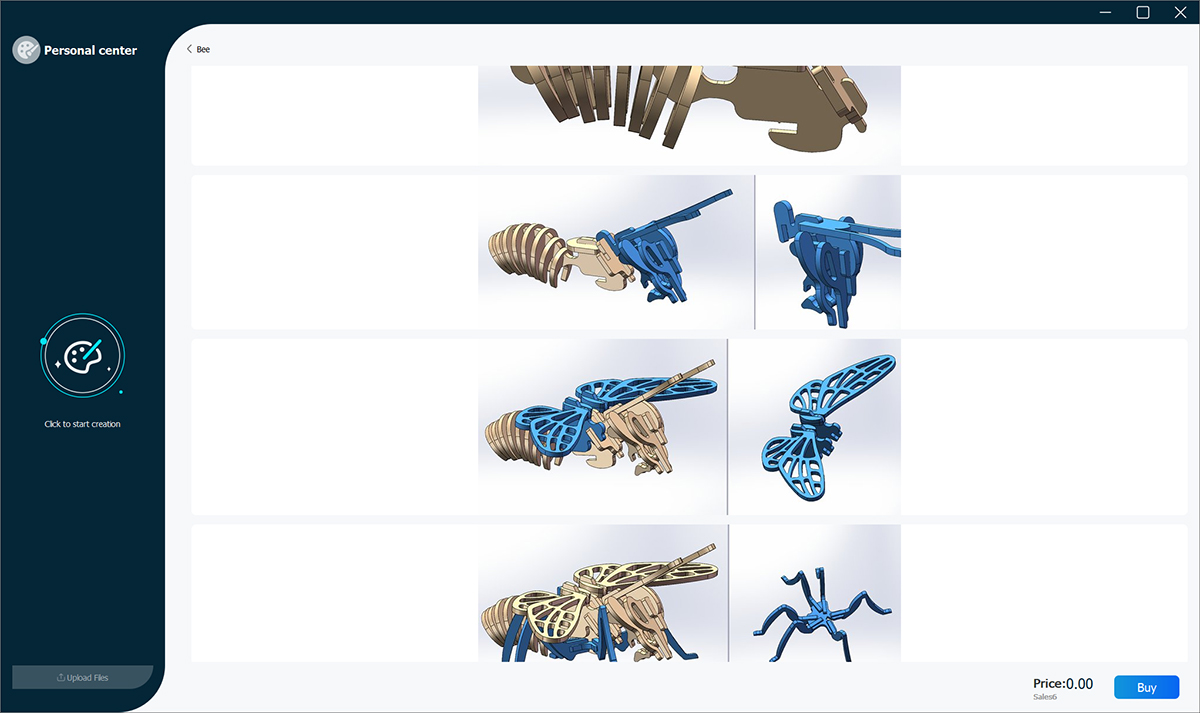

After starting, if you have registered, you will immediately receive an army of engraveable patterns and even more cut-out 3D puzzles, the models are lined up on 5 pages. We have to buy these, the goods are $0, so they are free. If you "buy" one of them, the Buy button changes to Use, which means you can use it.

You now have two options, either Use or "Click to start creation", both will take you to the same interface, only in the case of Use, the "purchased" sample will be loaded immediately.

The next task is to create the USB connection, this will definitely be needed. If we connected it to our computer and turned on the K8, we have to select the port in the lower right corner, it was Com4 for me, and we have to push the Connect button.

When we are done with that, then you can set up the Wifi, you will also need this, because the camera in the machine only works with a Wifi connection. If the USB connection is established, a Set Wifi button will appear next to Connect. By clicking on this, you can set the name of the Wifi in a small window and enter the password for the wifi. If this is also done, the program and the machine must be restarted.

When the software runs again and the machine is turned on, first the USB connection, then the Wi-Fi connection by clicking on Connect. Now we are ready, we can use everything!

In the case of the software, I'm writing about version 1.1.2, but since I've had the machine, it's already the fifth version, and it's expected that we'll get even newer ones.

The program is very simple and we can access all the important settings. When starting out, what will be important for you is adjusting the speed and strength of the head. You can move the head with small buttons, there is a console where you can see the currently running commands, you can run and save Gcode files, you can adjust the strength in the case of graphics, so the important things are here, simply and transparently.

At first, the program produced extremely annoying errors, but during the test, with the release of newer program versions (I started with software that was still very much in beta), they gradually disappeared. The subtitles appearing here and there have all been changed to English, and now essentially all functions are usable except for one. In this version, the camera must be calibrated every time it is started.

I am in daily contact with the developer, he sent the latest beta, but it is not perfect either, but seeing the pace of development, I have no doubt that this last bug will also disappear. It's not up to me, I sent the report, video and whatever I could. There is one more small thing, in one of the menus I think it would have been better to use tabs instead of a slider that can be scrolled to the side, but there is really nothing else. So the point is, these errors are dwarfed in terms of their number compared to the errors of the first tested version, and since I am in continuous chat with the engineer, I immediately report the errors found, which he corrects in the next version. So, by the time you get the machine, these errors may have already disappeared!

So far so bad, but what makes the software good?

The handling is really luxurious, simple, easy to use, so you can't get caught up in it. I really like that we also get basic editing capabilities, that is, you don't need to learn a complete vector graphics program in order to create simpler or even slightly more complicated patterns and texts. It's all incredibly simple, I think you'll love it!

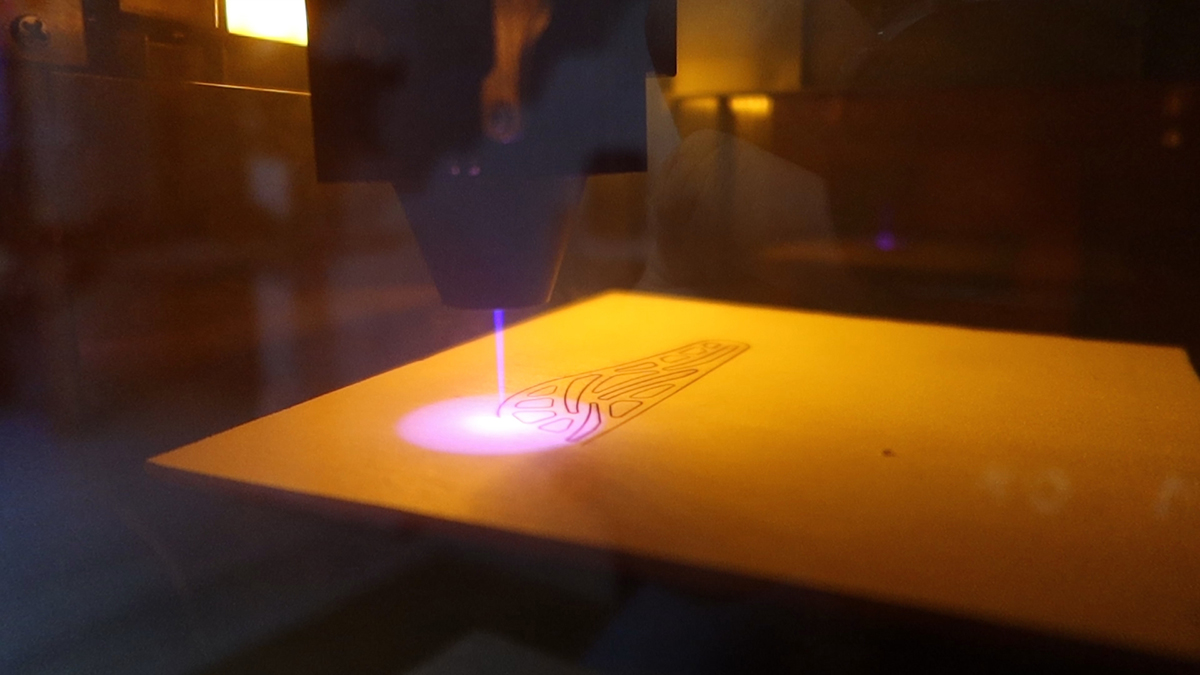

If we've come this far, let's go into more detail about one of the machine's greatest features, the built-in camera!

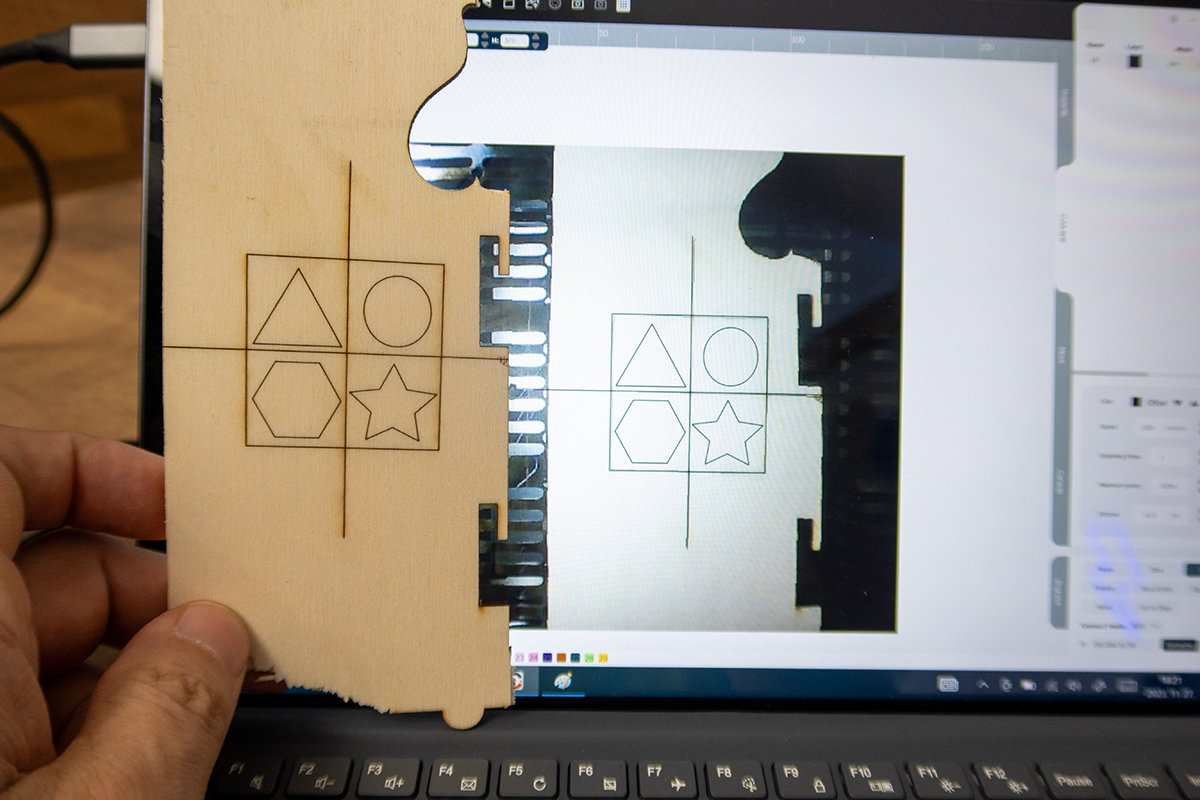

When I work on my larger machines, I have to be very careful that if I cut and engrave a material, the cutting and engraving do not move relative to each other (of course, now think of the typical blue laser machines, not the serious CO machines). Or to put it another way. If I have a cut-out small workpiece that I need to engrave afterwards, I have to set the starting point (0:0) of the head very precisely so that the engraving is in the right place on the cut-out workpiece. In the picture below, you don't see the image of the engraved material in my hand on the computer screen, but the plan of where the machine should engrave. I think the result was convincing!

This setting can be done with the camera in a matter of seconds and without error, because we can take a picture of the workpiece placed on the tray with the built-in camera, then in the CutLabX software we place the text or figure that we want to engrave in the right place on the photo.

No magic, no messing with setup. It is not a problem if the work piece is not standing straight, because the pattern to be engraved can be rotated, so it can be fitted to the work piece with complete precision using the camera.

It is important that you may need to calibrate the camera after installation. To do this, you have to engrave a target cross on a piece of cardboard (or a drawing board, only then you need to reduce the laser power), then take a photo, and then by rewriting the numbers shown in the upper part of the screen, you have to cover the engraved target cross with the target cross shown by the program. It looks more complicated in writing than in reality.

Now that we are more or less familiar with the software, the work can begin!

The 5-watt head I received knows exactly what the 5-watt head of every other machine does. You can cut with it, in the case of plywood I do not recommend thicker than 5 millimeters, but it is better to think in 3 millimeters. You can also cut pine with it, but this is more of a theoretical option, I don't recommend it.

You can engrave on many types of materials, but mainly on softer materials. Let's say with the right amount of time and patience, you can leave a visible mark on a steel sheet, but according to this, 10 watts is a reasonable lower limit. That leaves the softer metals, such as (anodized) aluminum, leather, wood, textile, acrylic, paper, so a lot of things. 5 watts is enough for these.

With the smallest, 2,5 watt head, I would rather only engage in engraving, not cutting. This is where it makes sense that you have to buy the extractor separately, because I wouldn't necessarily invest in it to engrave next to the 2,5 watt machine.

10 watts will be enough for a lot of things, you can cut even 10 millimeter plywood with it, you can engrave steel, so the range of possibilities expands quite a bit!

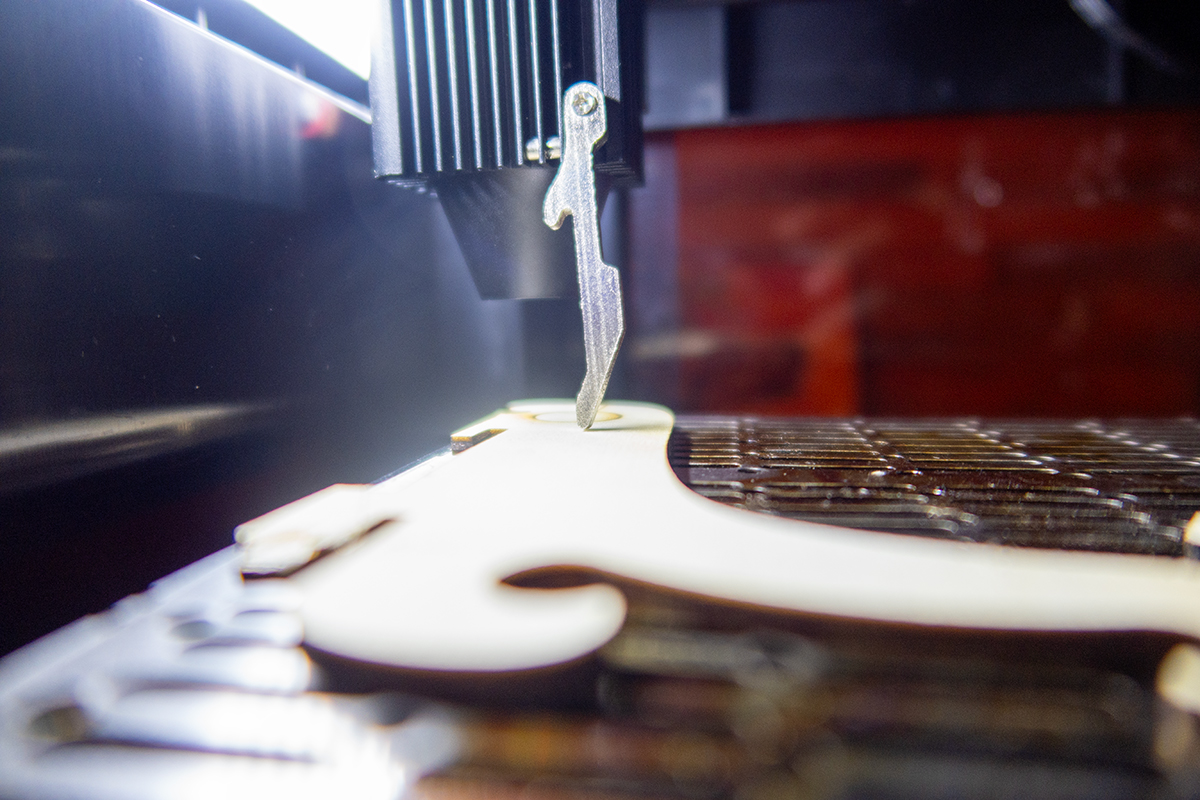

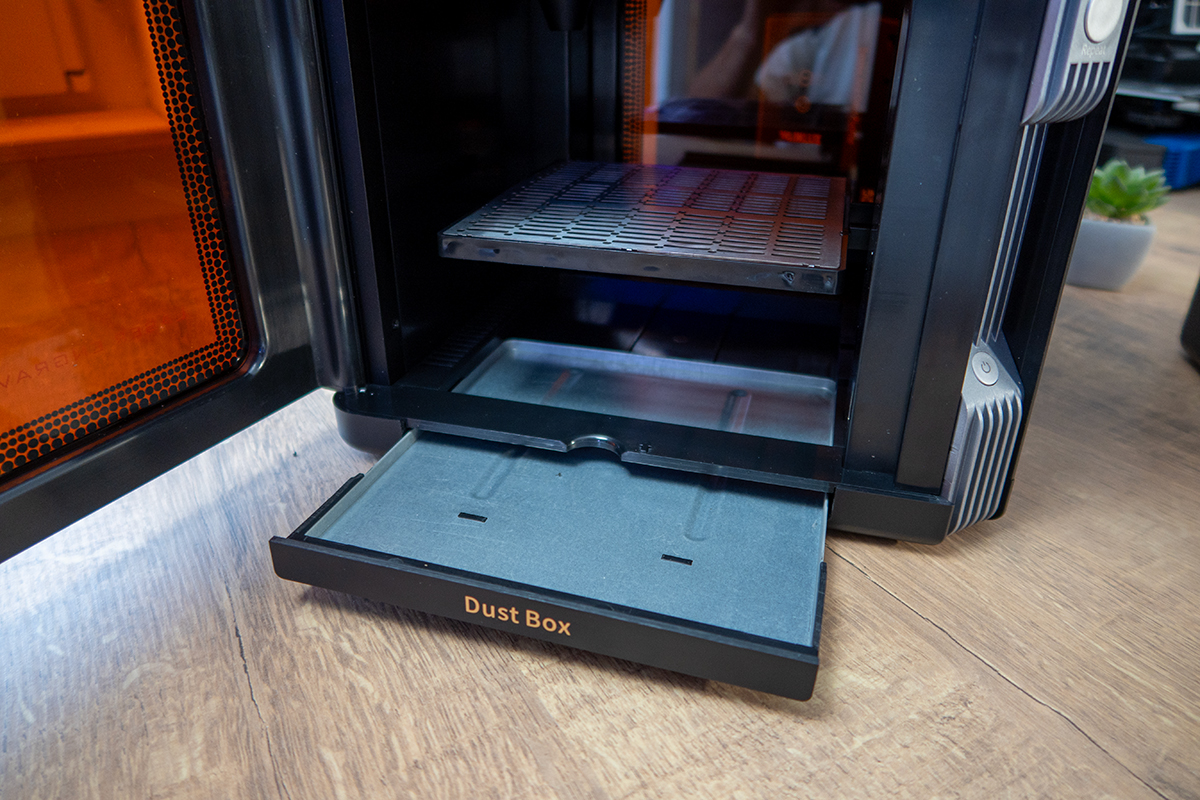

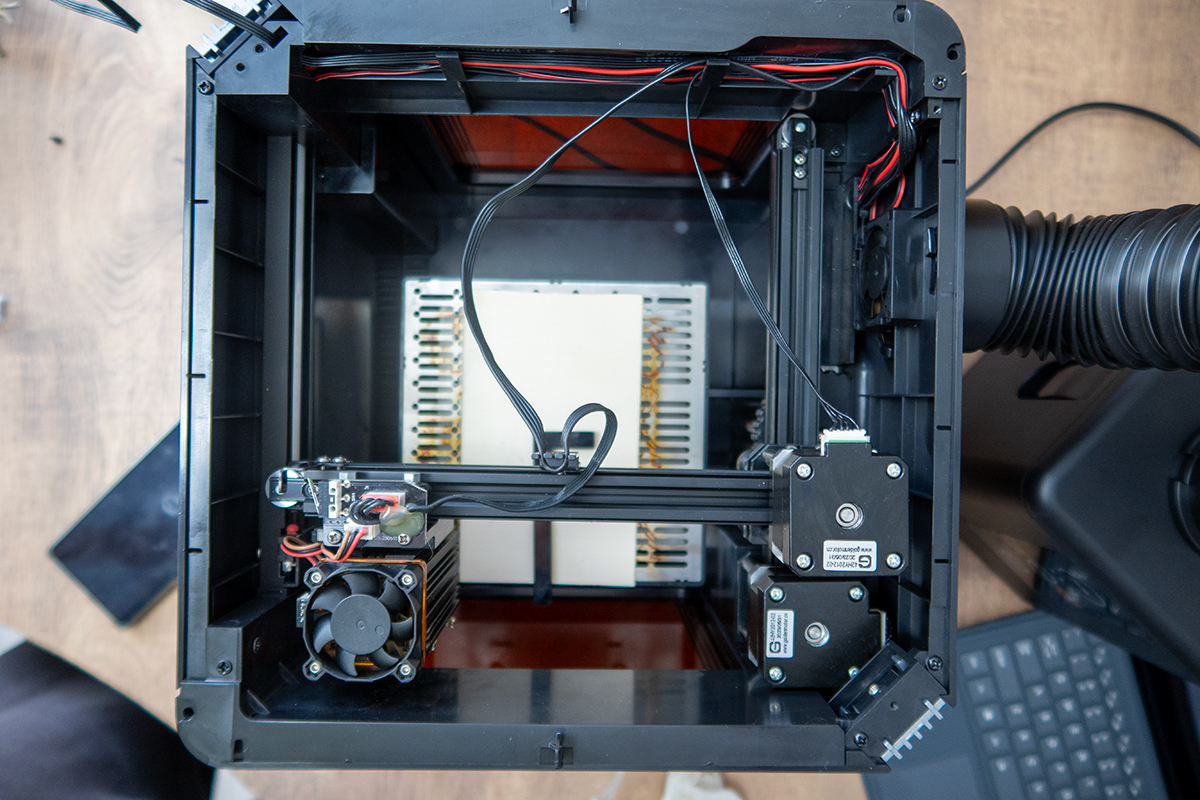

The interesting thing about the machine is that, unlike traditional solutions, we do not set the laser head to the material, but the material to the laser head. This is what the dial on the side of the machine is for. In other words, the 40-millimeter fixed focus must be adjusted to the material thickness by raising or lowering the tray holding the workpiece.

The metal tray is perforated. to make the cut more beautiful, but speaking among ourselves, this is only a half-way solution to burning the material. When you cut, there will be a lot of heat under the material lying on the sheet metal, which will burn the lower part of the material.

With traditional machines, we can use the honeycomb grid for this purpose, which I honestly admit is much better than the Wainlux solution. This is because the material lies on a fairly large surface, despite the holes, and where it lies, it becomes discolored.

In relation to this, the only thing in which this machine does not fulfill the promises, I can even call this a rather big slip, because the presentation material claims that it has a built-in Air Assist system. Well, that's not exactly true.

If you didn't know, the air assist is there to prevent the material from burning when cutting, and it's also good for creating much less smoke.

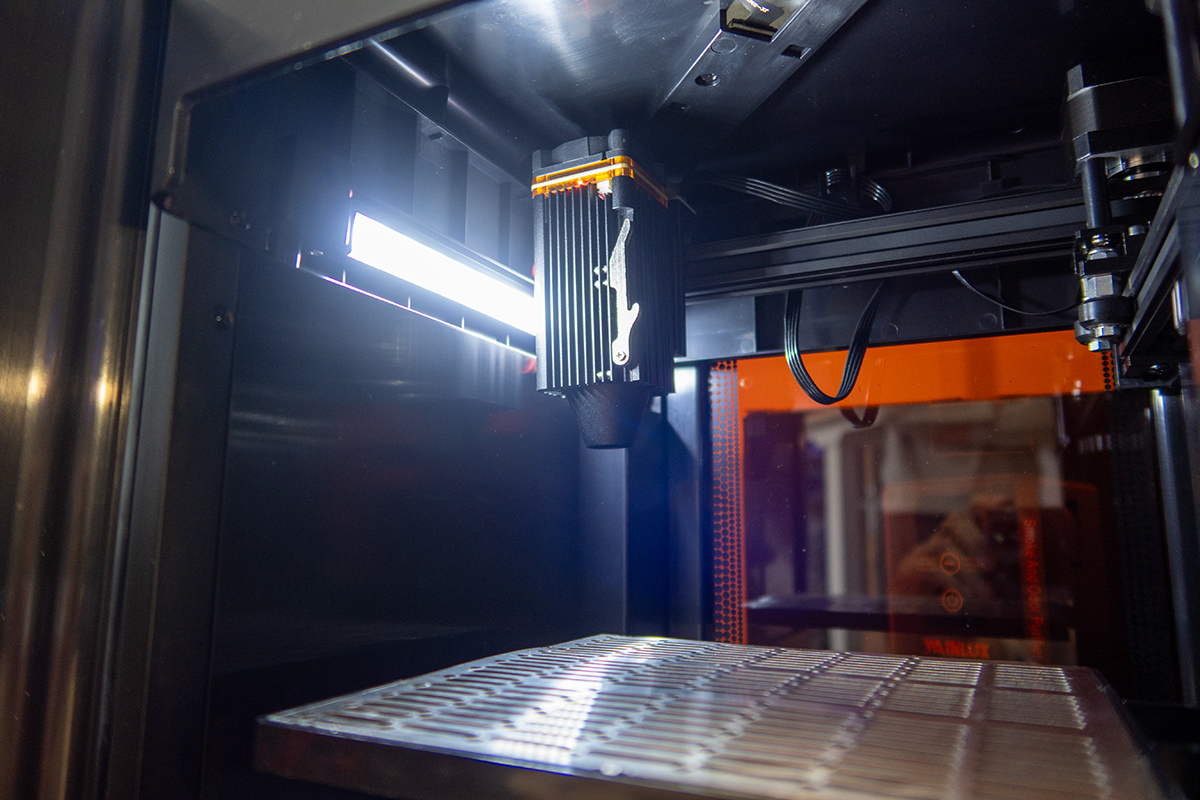

The air assist essentially consists of a pump, a pipe and a nozzle, which blows air at high speed on the workpiece during cutting, exactly at the point where the laser burns the material. Compared to this, in the case of the K8, there is a small but quite loud fan on top of the laser head, which blows some air downwards.

In all cases, there is such a fan on the laser head, just a smaller, quieter part. At Wainlux, it was believed that a fan with a higher speed delivers more air, so it immediately triggers the air assist systems. Well, it doesn't trigger it. It's much more than nothing, but it's not air assist by any means.

For 2,5- and 5-watt lasers, this is still in the category, but with 10 watts, especially when cutting thicker material, a good air assist is almost essential, which is not available here.

I think the system in the box itself is good. I took the whole thing apart like Floki took a doormat, I took a good look, the rail structure was well built by Wainlux, the tray lifter is also a normal piece, I like that an LED strip inside the box lights up while working. The wiring could have been more professional. There are no major faults, but there is a ribbon cable that I feel would have been better if it were a few centimeters shorter, because it just hangs like that.

I have already described many things about the use, but now I would like to summarize the quality of the work.

Installation is therefore very simple, and I think that the manufacturer has more than fulfilled its promise at this point, i.e. it has put a machine on the table that is a perfect solution for beginners. You don't need experience here, you don't need serious computer knowledge, because of the software, we don't need to learn a vector graphics program, because we can do the basic things without it.

It's great that there is Wi-Fi, but with this machine I would do without it because the manufacturer also provides the extractor, so the engraver can be right next to my computer, I don't need to build a cabinet for it, I don't need to design and implement an extraction system and I don't smoke with it not even under the neighbor's nose.

Wainlux also passed the exam with almost no marks in relation to smoke. Almost, because with 5 watts, cutting the 3-millimeter plate, it almost completely kept the odors inside. The engraver's box itself closes absolutely well, no air escapes, and the small extractor is absolutely fine on the highest setting. Okay, I'm not saying it's 100 percent, because there's a very tiny smell, so let's say it's 98 percent.

However, in the case of a 10-watt laser and thicker material, I think (in hindsight) that this suction will be little. Knowing how much smoke is produced at this time, I am almost certain that this extraction will not be sufficient.

There is one more thing that I dare not give an excellent grade for, and that is the volume of the exhaust. On the lower and middle levels, it's okay, although you wouldn't be able to sleep next to it, but on the highest level, the sound is almost disturbing. And not only because of the volume, but also because the fan of the copy that came to me is chirping at this level.

I don't know if this is because the fan is bad in the first place or because there is less air going through the filter than the fan can move, creating a vacuum between the fan and the filter, but it chirps.

The point is that in these two things, i.e. installation and extraction, the manufacturer has kept what it promised, even complete beginners can use it without having to think about further serious investments, such as a cabinet and extraction.

The third promise is the ease of work itself, as well as the software, and I think this is the point where you have to stop and raise your hat to the manufacturer, because working with the machine is simply as easy as slapping. The fact that I can fit the image to be engraved on the workpiece with the help of a camera, and adjust the cut with the help of a camera makes the work extremely easy, and also makes it more economical, because much less waste is generated due to the precise setting.

In other words, we can tick this point as well, using it is child's play!

In other words, to summarize what has been said so far, Wainlux kept all three promises. They created a machine that is easy to set up and use even for absolute beginners, and we don't have to worry about the smell or the smoke either!

What jobs do I recommend the K8 for?

Perhaps what I am writing will sound strange, but the only limiting factor compared to large blue laser machines is the size of the workpiece, which, as I wrote, is 13 x 13 centimeters (the tray is 15 x 15 centimeters anyway). Anything that fits in this size can be made with this machine in the same way as with any blue laser machine.

It is also worth buying the 10-watt one, because with that power you can already engrave on steel and you can cut through the same material thickness at a higher speed. However, take into account that, in my opinion, cutting larger material thicknesses will not be feasible due to the more smoke generated. In other words, the cutting itself is fine, but I don't think the extractor will be able to transport that amount of smoke.

So, if you want to cut, then in my opinion, 4-5 millimeters can realistically be the upper thickness, which even the extractor can get by with. The quality of the engraving is good, but this is not surprising, since the focus size is also appropriate, as I wrote, the frame structure inside the box is also absolutely well done, so we can work quite accurately.

There are two other things that I don't think went well. One thing I haven't mentioned so far is that we can also bring files to work from USB, but for some reason the USB connector was not placed outside the machine housing, but behind the front door, in the lower right corner. In other words, if you want to remove or plug in the drive, you always have to open the door. I'm not saying it's useless, I just don't understand the concept, the reason why it's there.

The other is that they could have devised a clip-on solution for the edge of the tray, which could be used to fix the work material.

Here I have to go back to the very beginning of the article, because I promised to tell you what the L-shaped magnetic thing that is among the accessories is. Well, for that. In other words, to fix a textile or paper with it, for example.

But it can be used not only for that, but also for the fact that if you need to make more of a smaller ticket, then this L-shape can be the template into which you can fit the tickets one after the other. That way, the workpiece will always be in the same place.

Sum it!

This article has become much longer than usual, but not by chance, there was plenty to write about, and I am sure that there will still be things that I have written in addition, because I forgot about it at first.

If someone were to ask me now, after a few weeks of use, "how did the Wainlux K8 become perfect?", I would tell them that it wasn't perfect, but almost. There are still small, not nearly annoying errors, some of them related to the software, but this can be fixed. The hardware error can't even really be called an error, since the placement of the USB A connector is more strange than bad.

In terms of hardware, the metal tray could have been better. I would have been happy with something depressing. The picture of the built-in 2 megapixel camera could be a little better, which often gives an acceptable picture only after the second exposure, with which the work can be set precisely. I'm not saying that it's exactly a tenth of a millimeter, but as I calibrate the camera, you can think about it with an accuracy of 0,4-0,5 millimeters, and that will come before everything.

Although the machine is intended for absolute amateurs, I dare to recommend it not only to them, but also to those who simply do not need a larger machine for their work. For those who don't need to build a complete engraving table with a box, extractor and everything, because they either only work with small things, or only very occasionally.

So the Wainlux K8 itself has really turned out well, it really fulfills the promises, that 2-3 percent plus is missing from the hardware, and that 4-5 percent from the software to really be 100 percent. I could live with so many shortcomings of the hardware, and the software improves from version to version, so it would be a shame to bury the K8.

Well, then let's look at the prices! Let's start with the fact that the manufacturer delivers everything to us from an EU warehouse, so we don't have to pay additional customs and VAT, and we get the package quickly. Despite the cool design and many nice features, I don't think the machines cost much. You can find the products by clicking on the link in the list below. In any case, you will use the HOC-HU coupon code, the prices look like this:

Wainlux K8 2,5 watts - not yet available

Wainlux K8 5 watts - HUF 128

Wainlux K8 10 watts - HUF 145

Wainlux MD22 Mini extractor - HUF 58

Glass spinner for the machine - HUF 17

You can also buy the product on Aliexpress here: