Real professional work - here is the Atomstack A24 Pro laser engraver

Whether a laser is good or bad can be decided by many small things. Small deficiencies in ability can cause the downfall of a machine, which an uninitiated eye and inexperienced customer cannot even think about. With the Atomstack A24 Pro, you won't find such a mistake!

contents show

Watch my video presentation too!

It's been quite some time since I've had a medium-sized desktop laser, and I'll be honest, I wasn't too satisfied with the last one I tried. It was in vain that it had a strong optical power of 20 watts, if the weakness of the structure and many small annoyances made it bitter, or rather made it difficult to use.

For this reason, when the representative of Atomstack contacted me, I did not say no to a subsequent test. Of course, that's not the only reason I didn't say no, but also because the relationship with the manufacturer can be useful, so if a manufacturer contacts me, I don't usually say no. And of course also because the A24 Pro promises to be a really exciting machine.

As I have already indicated several times, one of the great advantages of my job is that I don't have to take every test, only the ones I feel like taking. For this reason, I rarely have to write about bad or, rather, not very good products. Of course, sometimes it slips in and out, as the paper form can be tricky.

Fortunately, the Atomstack A24 Pro would not have been worse than what the paper form promised, but also far exceeded it.

More on the details later, let's get to know the machine now!

Below I will describe the factory specifications, and of course you can see the factory data regarding the types and cutting thickness of the materials that can be cut and engraved.

Specification:

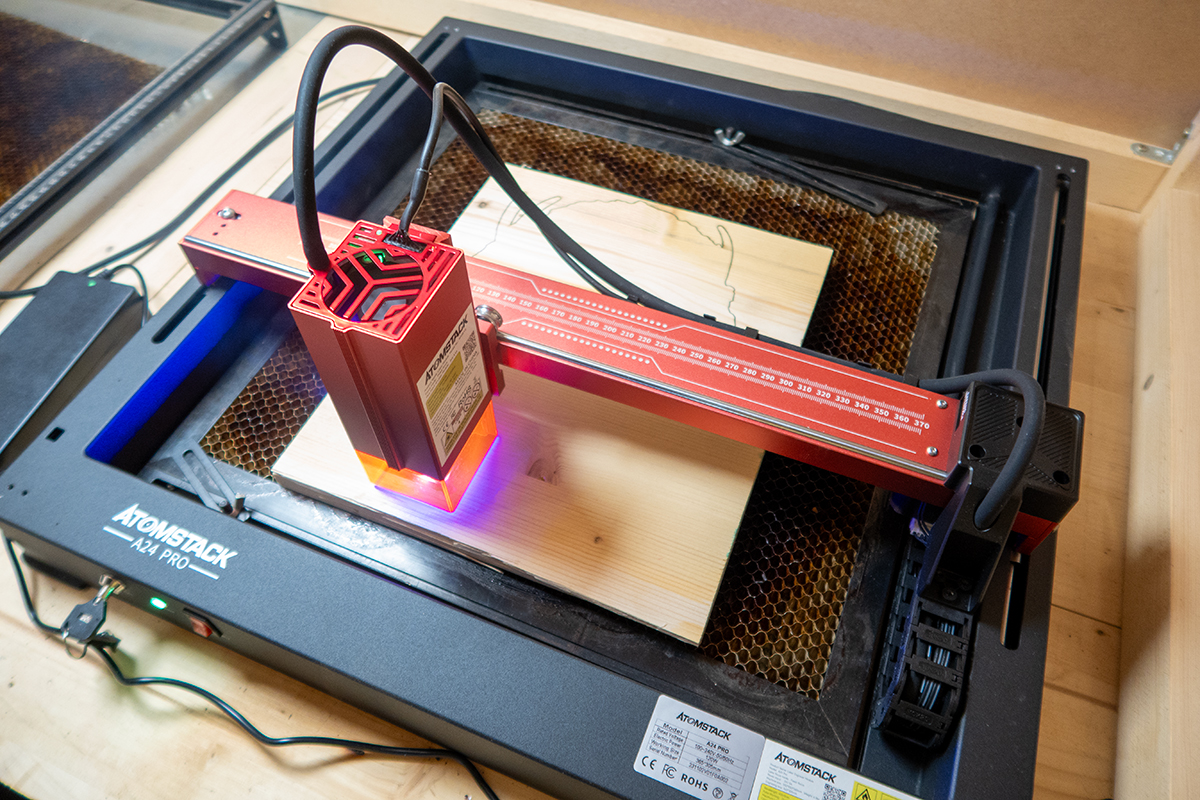

ATOMSTACK A24 PRO is a laser engraver and cutting machine with 24 watt optical power. The machine can be used without assembly with its full aluminum alloy frame, which is cast in one piece. The device has a compact engraving area of 365 x 305 mm, making it an ideal choice for smaller workshops or home use.

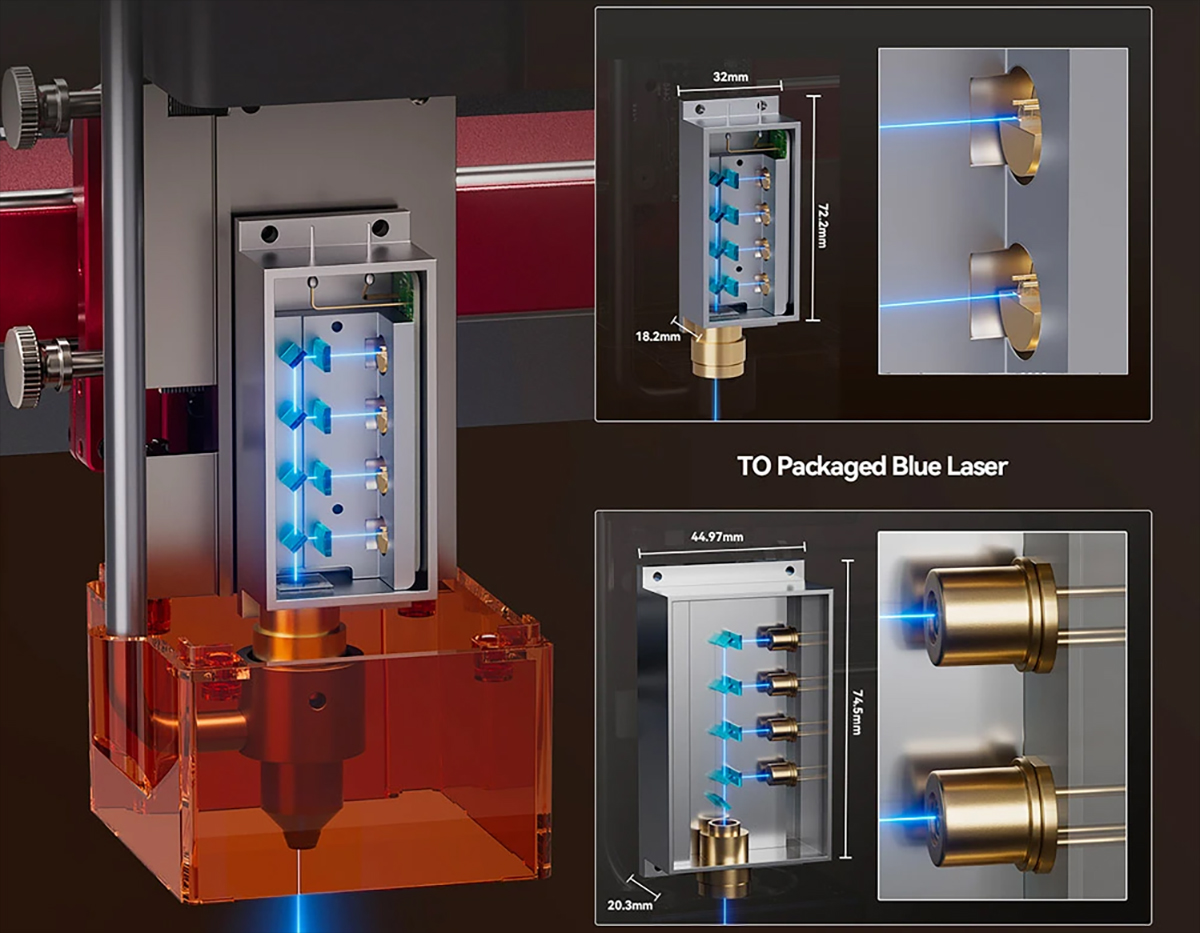

The four 6-watt second-generation optical power lasers in the machine provide a total of 24 watts of power, which allows for 18 mm thick softwood, 10 mm thick black acrylic, 15 mm thick plywood, 5-layer laser-specific vinyl and up to 0.05 mm thick stainless steel sheet cutting in a single step. The fixed focus design enables fast and accurate focusing in just 10 seconds.

The second generation blue laser technology further reduces the focus size of the laser and significantly improves the cutting capabilities. The ultra-fine laser focus area is only 0.06 x 0.06 mm, which enables easy cutting of 20 mm thick plywood and 30 mm thick black acrylic. In addition, reflective stainless steel, ceramic and glass surfaces can also be engraved directly. The engraving and cutting speed is 40% higher than the average models, and the extreme cutting effect is comparable to that of a 300W CO2 laser engraver (this is a "slight" exaggeration).

As I wrote above, the basic frame of the machine is made of one piece, and the X-axis is formed by a two-axis guide rail structure. During work, the vibration is very small, so the machine does not resonate even at a speed of 600 mm/s.

The cross laser positioning is a new function that provides a simple solution for determining the position of the laser head, enabling perfect alignment for engraving.

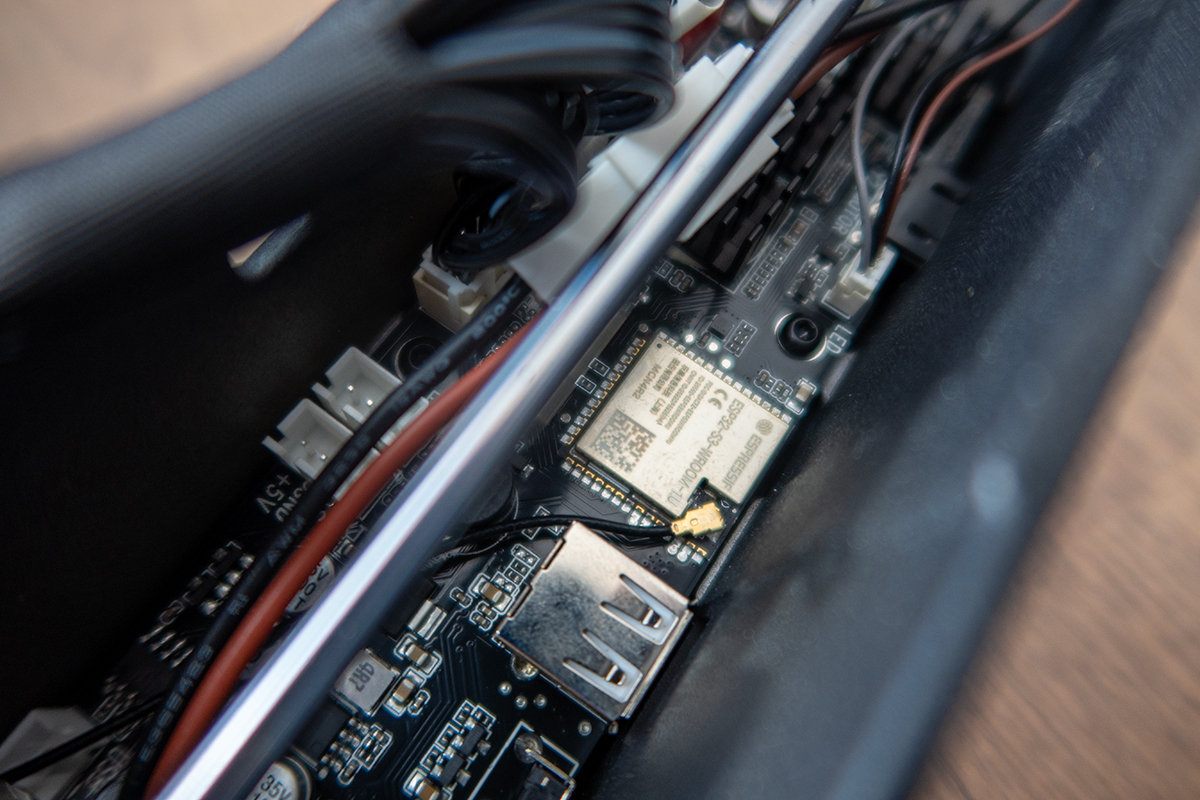

The ESP32-based, 32-bit self-developed motherboard enables faster data reception and processing. Optional accessories allow automatic focusing and continued engraving after power failure.

The mobile app developed by ATOMSTACK is available in most Android app stores and the Apple APP Store (can also be downloaded by scanning the manual's QR code). The app is multi-functional and provides a new control experience.

The panoramic protective cover filters 97% of ultraviolet light, thus protecting the eyes of the users and those around them, so they do not need to wear protective glasses during use (I would also argue with this, the reflected light also damages the retina).

The machine is widely compatible with various mature engraving software such as LaserGRBL and LightBurn. It supports Win XP / Win 7 / Win 8 / XP / Win 10 operating systems as well as Mac (LightBurn). Engraving file formats include NC, BMP, JPG, PNG, DXF, etc.

As a safety protection, it has an emergency stop button that allows you to stop the machine immediately in unexpected situations. It is also equipped with a limit switch and a gyroscope for safer laser work.

So far, this has been the dry manufacturer's specification, now the experiences can come, there are plenty of them!

Experiences

As I wrote above, a laser can fail due to many small flaws or design problems. Basically, it can be said that due to the strength of today's lasers, they can be used for many tasks, but in order to be truly usable, they must meet many expectations. For people like:

- Stable frame structure that does not deform even over a long period of time,

- Vibration-free operation even at high speeds,

- Precise rail design,

- Precise carriage and head movement,

- Precise and easy adjustment of the laser position,

- Adequate optical performance,

- Appropriate electronics including limit switches and stepper motors.

I could go on and on, but perhaps these are the main aspects that should be considered in the case of an engraver/laser cutter. I also went through these points when examining the Atomstack A24 Pro.

- Frame structure

Pro: You could already read in the specification that the frame structure is made of aluminum, but we don't get the usual bolt-on frame, but an extremely solid aluminum casting. The frame of the machine is cast in one piece, and everything from motors to electronics is located within this casting.

An extremely big advantage of this thing is that it cannot be assembled incorrectly, since it does not have to be assembled. The frame screws will not come loose, as there are no screws. The frame will not twist or deform, as it is made of one piece.

Cons: The thing has one drawback, the size of the machine cannot be expanded, and the working area is smaller compared to machines with a traditional frame.

- Vibration-free operation and precise rail design, precise carriage and head movement.

I discuss these three points together because they are strongly related. In order for the operation to be vibration-free, the rail structure and the moving mechanisms must be precise. Well, in the case of the A24 Pro, we get solutions that I myself have not come across in the cheaper, home, hobby category.

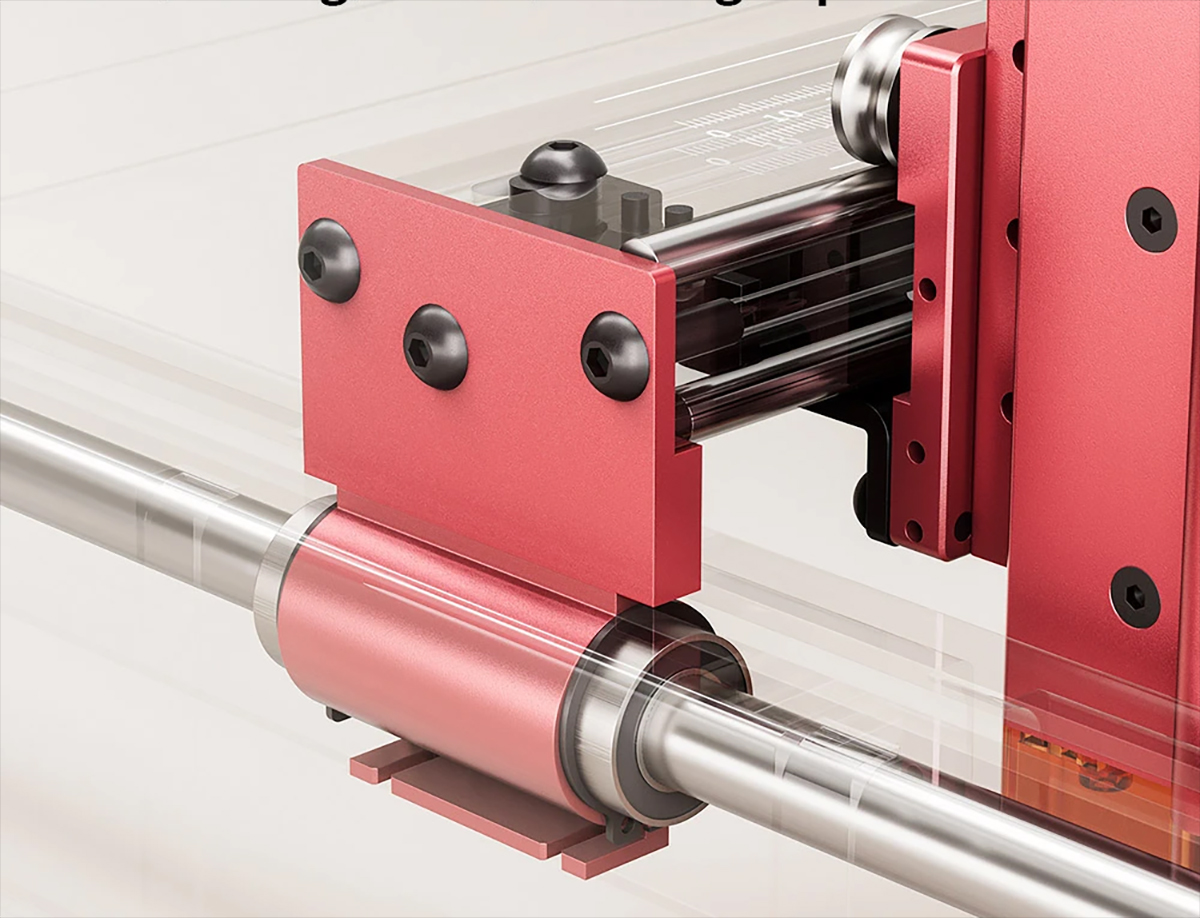

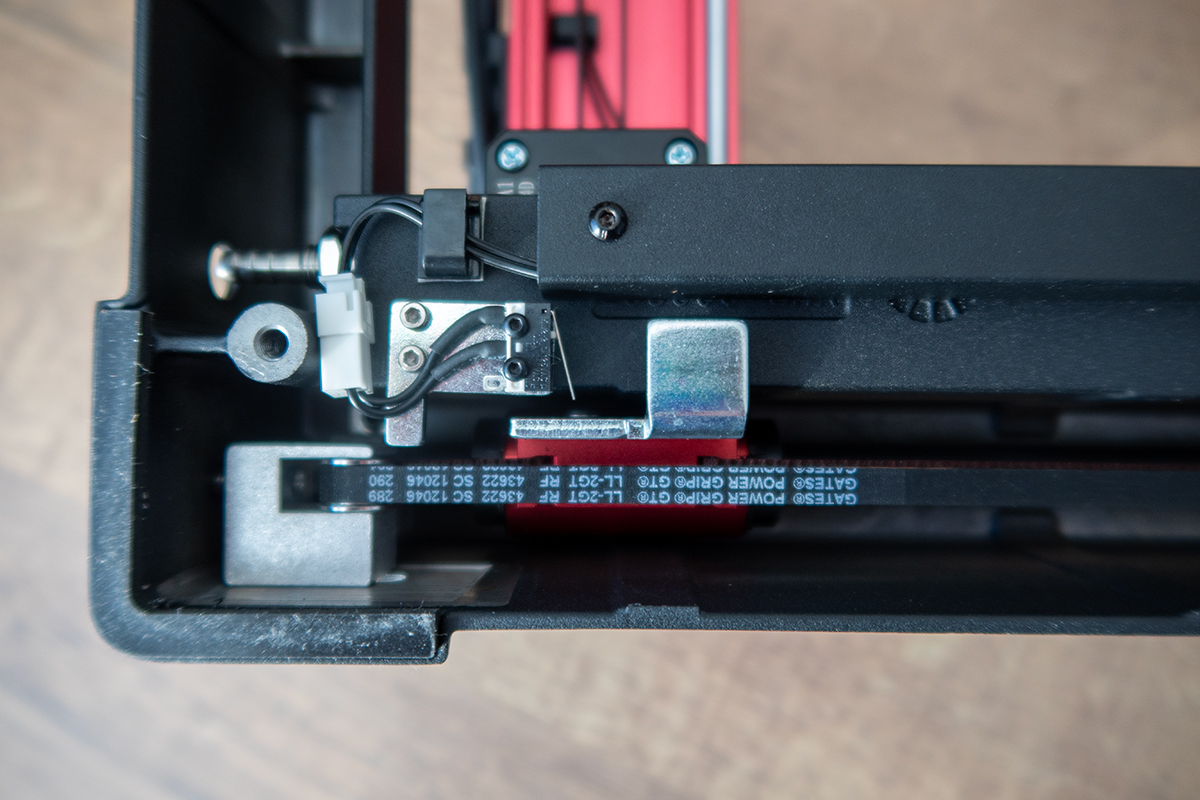

With this machine, we do not find the usual aluminum profiles and the rubber rollers that run on them. They simply don't exist, they omitted this solution in the design, and how well they did that they omitted it, because because of this, we got such a precise movement that is really rare.

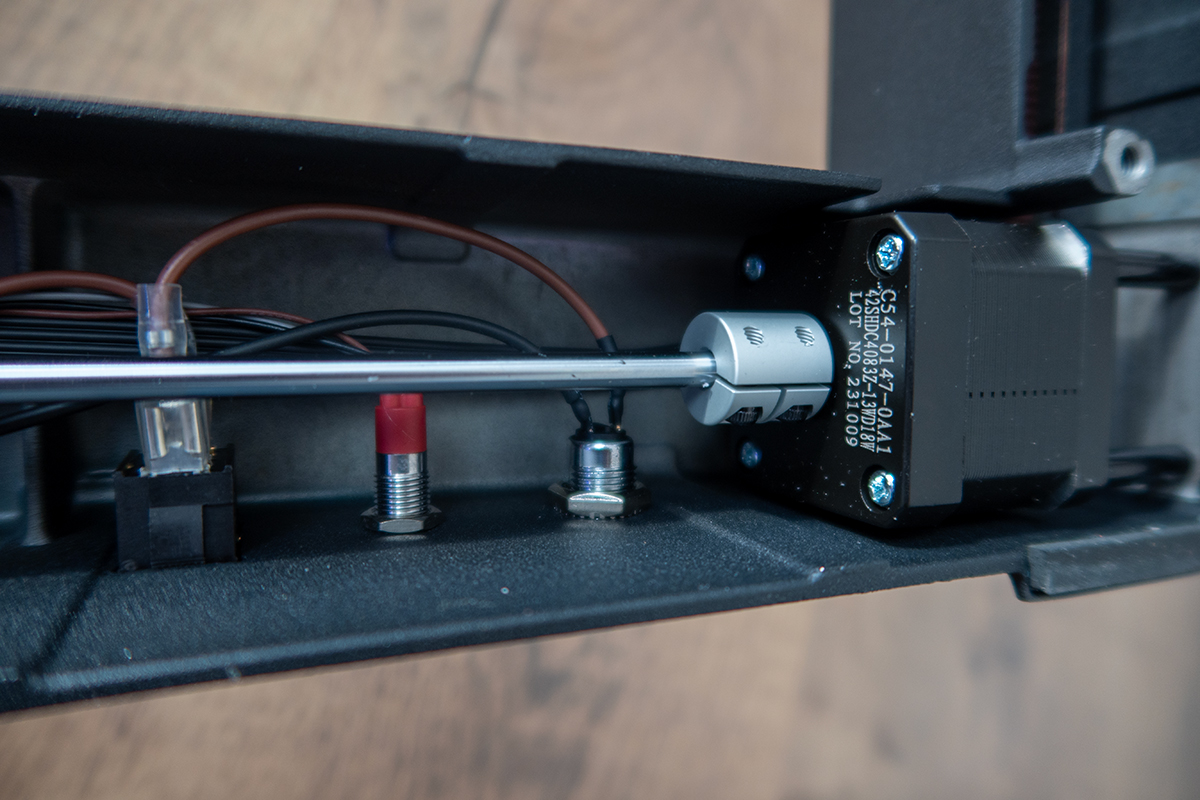

In the case of the Y axis, for example, one stepper motor operation remained, but this one motor drives two axes, one on the right and one on the left. Instead of rollers, the part containing the X-axis, i.e. the laser head, slides on a steel rod, so the structure cannot be jammed, the right and left sides are guaranteed to move together with infinite precision.

But this is not the end of the matter, because the head moving on the X axis has also received a very special solution. There are no rubber rollers here either, instead there are steel rollers, which, of course, do not roll on aluminum, but on steel rails. Needless to say, this solution is extremely durable, absolutely wear-resistant and enables extremely precise movement.

These solutions have several positive effects. One is the vibration-free operation, and the other is that I have not experienced with this machine that the head would not have followed the same path during a complex job requiring both cutting and engraving. What does this mean in practice?

Let's say I want to create a map that consists of several layers. I engrave the top layer of the map, this is where the roads, city names, etc. go, these are not cut out, but engraved into the plywood.

In the second pass, I cut out the locations of the lakes and rivers on the map. This is necessary so that the blue-painted plate can be seen under the cut-out parts on the second, lower layer, where the waters are. I hope you can imagine the scene, it will be something like this:

Now, if the head does not move precisely, what happens is that the cutting and engraving will not overlap properly, i.e. the machine will not cut the plate where it should, but instead the engraved part will shift by up to 1-2 millimeters. from parts.

You can imagine how ugly the end result will be!

In the case of a good machine, due to the precision of the movement, such an error cannot occur, and it becomes possible to create works that could only be created with large, expensive and professional machines. Of course, the work will be somewhat slower than with a million-dollar machine, but this is not so decisive in the case of hobby projects.

- Precise and easy adjustment of the laser position

This is the point that can really annoy you. The fact is that in order to be able to produce accurate and precise work, you need to be able to position the laser with an accuracy of a tenth of a millimeter. The easiest way to do this is to turn on the laser for positioning in the control program (in this case there is only minimal power, it does not burn the material, it just lights up), and the focal point of the laser by moving the carriage along the X and Y axes manually (that is, completely manually ) you set.

For this you will definitely need one thing, to see the focal point of the laser on the workpiece!

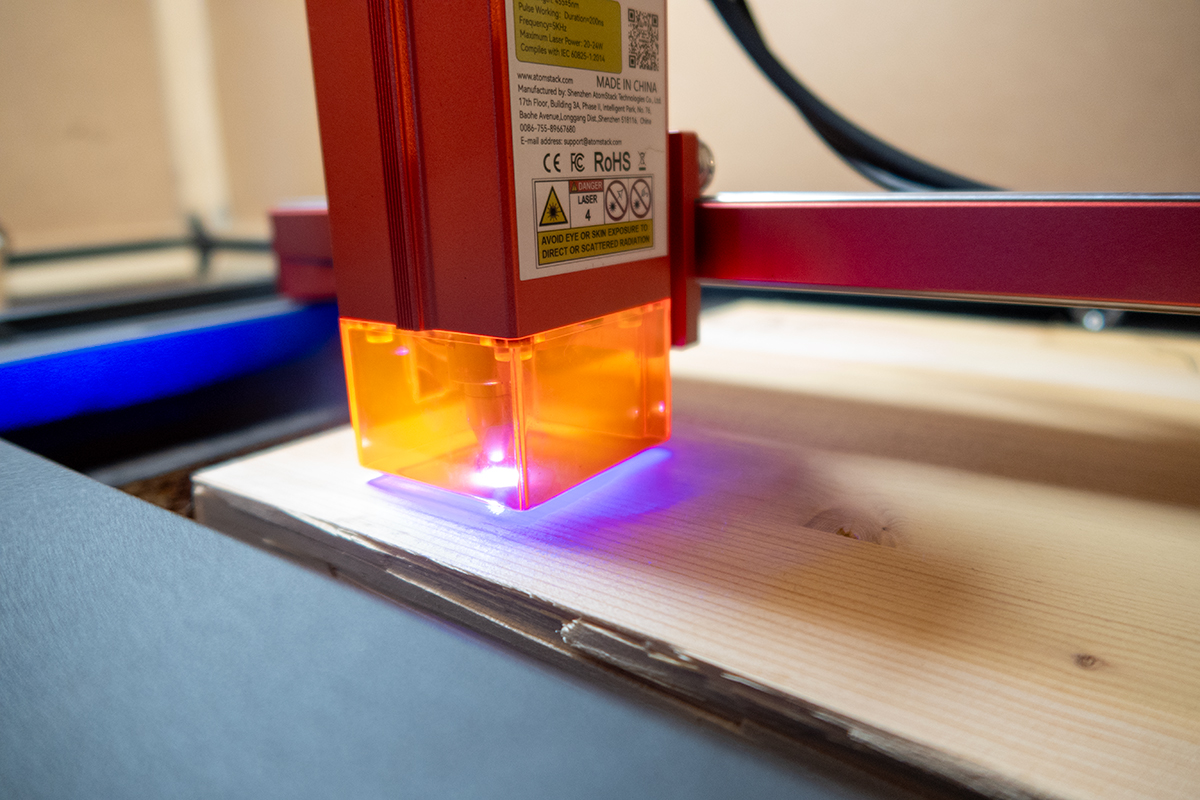

Now you can think about why you shouldn't be able to see it, but unfortunately there are times when you can't. There are laser heads where the head reaches almost to the workpiece, and we can only see the material under the head through a small Plexiglas window. This plexiglass is also colored to filter out harmful radiation while working.

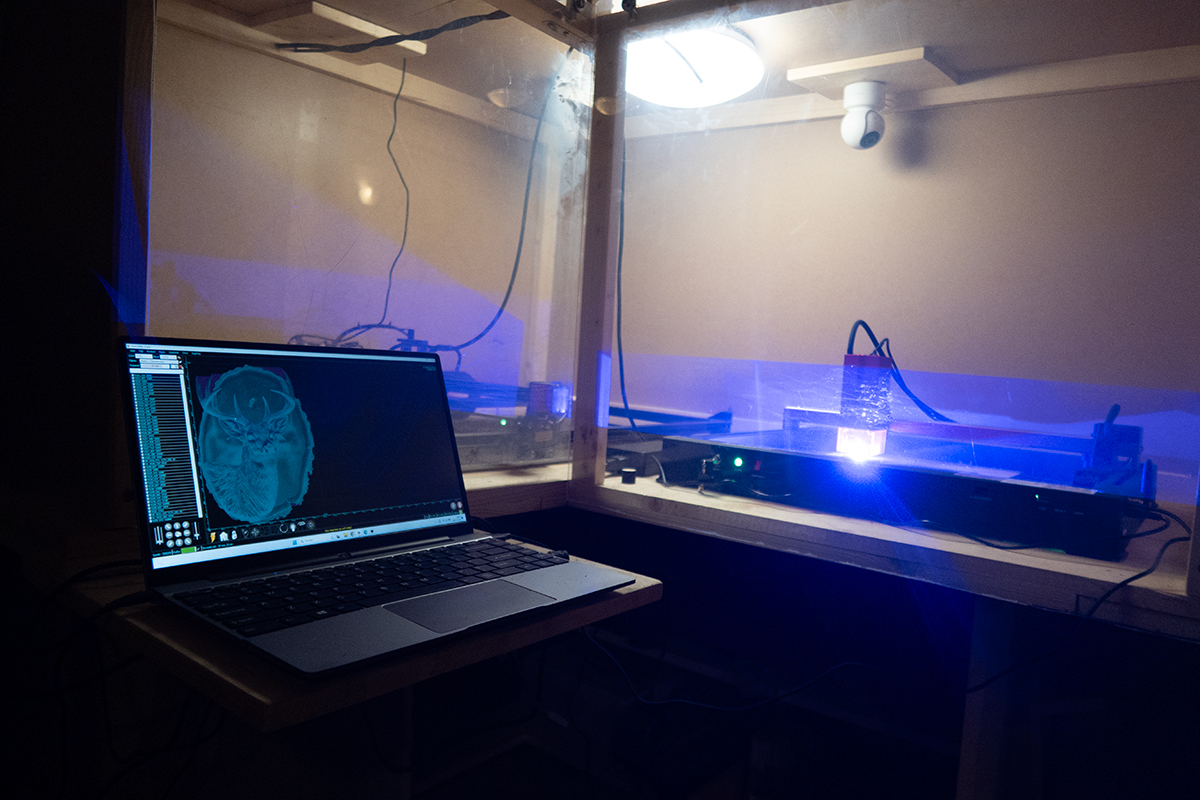

What happens with such a head? If the room is bright enough for us to see while working, we cannot see the laser light on the workpiece through the plexiglass. If we turn off the light and are in complete darkness, we can see the light of the laser, but we cannot see the machine or the workpiece. So what happens? It is not possible to precisely adjust the laser on the work piece, in short the machine will be unusable even for moderately serious work.

What is good design? One that can filter the light if necessary (we don't want to wear glasses while working), but at the same time does not cover the workpiece or the light of the laser on the workpiece.

Specifically, I usually take off the little skirt that is placed on the head to filter the light and I prefer to use the glasses provided with the machines. To do this, you need to be able to take off this skirt. With the Ortur 10 watt head, this is clicked in, and with the Atomstack A24 Pro, the situation is even better, with this machine it is held in place by magnets, which means that it can be easily removed and put back.

Maybe you still don't feel the weight of this problem, but this "error" specifically decides for me whether I will like the given machine or not, whether I will be able to use it or not.

- Adequate optical performance

That is, how strong is the laser. There are many of us, we use laser engravers for many different things. those who only want to engrave on soft materials will be able to create with an older 2,5 watt laser, and those who want to cut 10 millimeter plywood will need the 30 watt laser. However, even if this is the case, I dare to say that performance is never enough, that is, the more there is, the better.

The situation is that if your machine is strong and your machine is good, you can use the head with a higher maximum output with a lower output or engrave at a higher speed. Both have advantages. A head used at a lower power will fail much later, and engraving at a higher speed will be faster, meaning that the head and the machine will be used for a shorter time, and you will also save time.

In short, the higher the performance, the better, because the faster you can work or the more variety of work you can do.

Atomstack A24 Pro is 24 watt, the head contains four 6 watt lasers, their light is collected in a beam. This is the most powerful machine I've tried so far, and interestingly, even after the most powerful 20 watts so far, you can feel the power plus what's in the machine. I'd say it feels like 24 instead of 30 watts after the 20 watts. I don't know what this is due to, but I think the fact that I can cut 2 cm thick pine boards without any problems says it all. At least for those who have already tried to cut 2 cm thick pine with a smaller machine.

- Suitable electronics, motors, limit switches

I won't elaborate on this, stepper motors can be noisy or work imprecisely. The limit switches can be in the wrong place, they can be poorly fixed, they can be of poor quality, and these can greatly affect the work and increase the amount of scrap.

However, there are a few more things that I took notes during the test, I will write about them a little more!

- It's a small thing, but it's a very good thing that, unlike most machines, in the case of the A24 Pro, the power cable and the USB cable are routed to the side of the machine, and not to the front, towards you. It has already happened with other machines that my hand got caught in the cable while I was working, I pulled the machine away, pulled the cable out of its place.

- It also has built-in Air Assist. In practice, this means that the Air Assist rubber tube must be connected to the back of the machine, to the stub on the frame, and from there the built-in, hidden tube brings the air to the head and the workpiece. I would like to note that the Air Assist nozzle itself is also professional, it blows the air in the right place and with the necessary strength. What is also very important is that due to the design of the head and the nozzle, smoke does not reach the optics, so there is no need to clean the lens. This is also flawless!

- The cable whip and ribbed belts also run inside the frame, so the car will never get stuck due to getting caught in a cable, and the belts do not need to be cleaned, because dirt does not get inside the frame.

- It's a bit unnecessary for me, but for beginners, the laser crosshairs that the head projects onto the workpiece will come in handy for positioning the head. It makes it very easy to adjust the head to the exact position if you want to perform several work processes on the same material. For example, as I mentioned in the article, you want to cut and engrave the material.

- The machine has a key switch, which is very useful in households where children can access the machine. In other words, it is rather very safe, the locked machine cannot cause accidents or injuries.

- The fact that the machine does not need to be calibrated or set up, or the tension of the rollers and belts checked (the latter is possible if it is needed later), you turn it on and use it makes the work awfully easy.

Some more practical experience may come!

I take all engraving tests seriously, I invent projects for them.

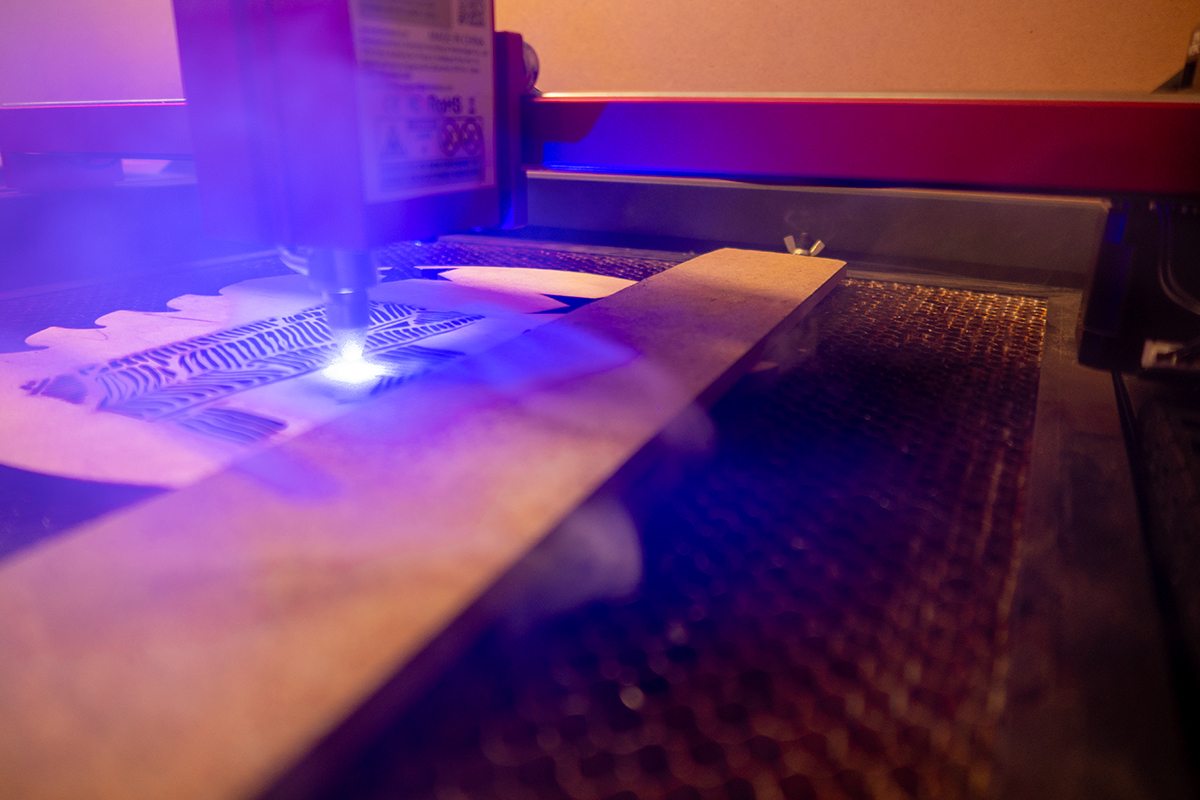

For this machine, I chose a simpler engraving on plywood as a start. The finished graphic is made with extremely fine, thin lines. I'm not saying I haven't seen this quality before, but I'd say it was one of the best I've seen so far. When engraving, it might be worth turning off the Air Assist pump, you get a completely different design that way.

The second project was to make a candle holder. For this, I chose 4-millimeter birch plywood, I was curious at what speed it would be able to cut through the material in one pass, and I was also interested in how Air Assist works with the relatively low speed and high laser power.

Well, I had a very good experience. I was able to cut at a good double the speed of my own 10 watt machine, but what was even better was that the high output made the job less sensitive to the quality of the plywood.

Please understand that the amount of glue in plywood is not equal and distributed between the layers, which is why the 10-watt laser cuts through the material in the first pass, but where there is a lot of glue, it may take 3 passes. In the case of the A24 Pro, I never had to make a second pass, which made the work a lot easier (I didn't have to cut the uncut parts with a snitcher after cutting), and of course it also had a beneficial effect on the duration of the work.

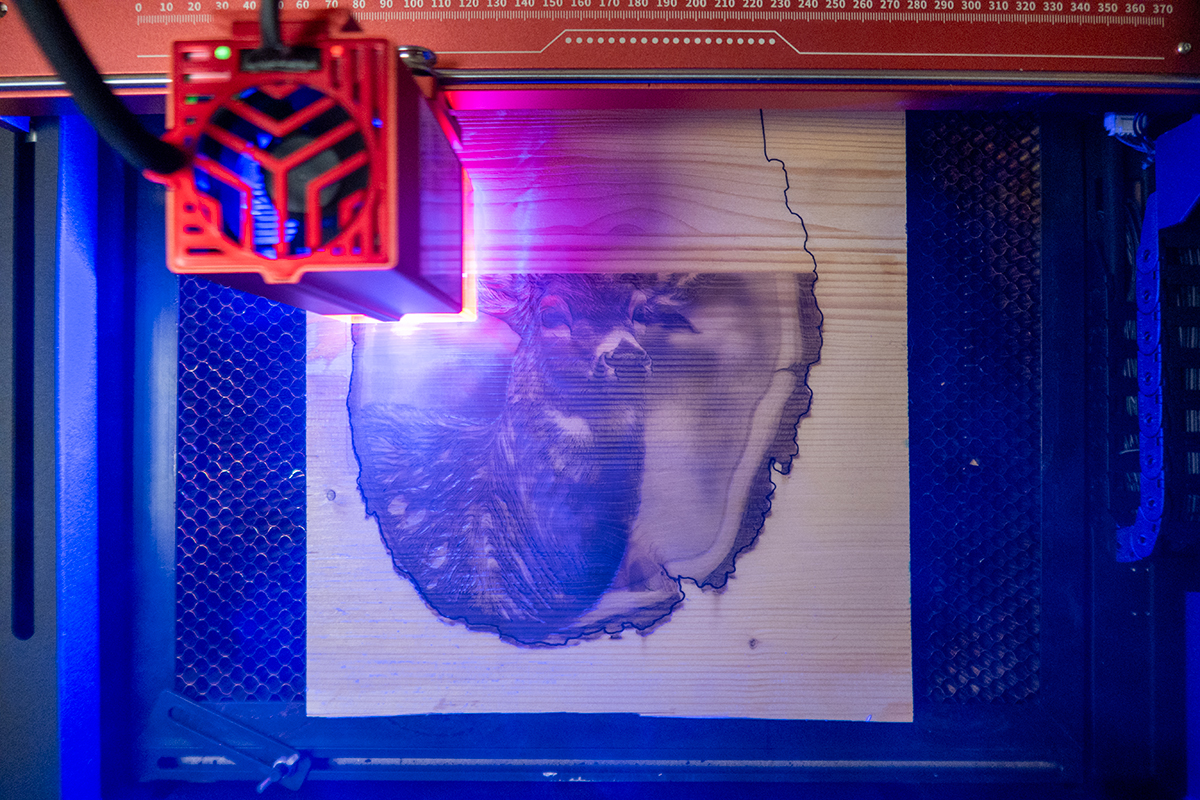

For the third test, I chose a slightly more extreme task. I engraved it on a glued pine board, and then I cut around the engraved area. The extreme in this case was the thickness of the material, I worked with a board thickness of 2 cm.

The pine board is not an easy material, because there are resinous parts inside that can even catch fire, and if the settings are not good, the board can burn during cutting. The purpose of this test was also to test the precise operation, that is, as I wrote above, I was curious as to whether the laser would be able to accurately follow the outline of the engraving.

I didn't find a fault here either. To prevent burning, I did not cut through the material in one pass, rather I chose a higher speed and the laser went around the cut twice. Air Assist worked great, relatively little smoke was produced, and the material did not burn inside. The accuracy of the cutting and engraving was super, so the sample made during the test ended up as a Christmas present, bringing great joy to its new owner.

Conclusion

In my previous engraving test, I showed you a machine that even amateurs can use. It was small, practical and simple.

The great thing about the Atomstack A24 Pro is that it doesn't require as much practice as the previous machine. In other words, no, this is not true, because it does not actually require any practice to make the first simpler objects.

As I wrote, you don't need to assemble it, you don't need to calibrate it, you don't need to adjust it, you don't need to adjust the rollers, you don't need to adjust the tension of the belts. You take it out of the box, put the laser head in its place, connect the one piece of cable and the machine is ready for use.

However, as easy as it is to use, this machine has the potential to make some really professional stuff with it. Amazingly powerful, fast and extremely accurate. I really don't know any negatives other than the relatively small work area, but it's not very small either, since the 365 x 305 millimeter area will be enough for most of us.

During the test, I did not have a single bad experience, so I dare to recommend the A24 Pro to both beginners and professionals.

Of course, it should not be forgotten that the price of the machine is not low. Of course, this is also a matter of comparison, because the performance comparable to the smaller CO machines and the marginal maintenance costs compared to them more than compensate the customers.

So, if you are looking for an absolutely professional machine that is also suitable for beginners, look no further, you have found it. If you buy it as a beginner, you will definitely not outgrow this machine in a year and a half, because it has an insanely high potential, with which you will be able to make amazing things. For me, the Atomstack A24 Pro deserves a solid grade of 5!

You can buy the machine by clicking on the link below, a HOCTA24 with a coupon code you get $50 off the list price!

Atomstack A24 Pro laser engraver