Ortur Laser Master 2 Pro - Ben Kenobi turns yellow with envy

It can be used to cut, engrave on wood, metal, glass, plastic and thousands of other things.

contents show

Check it out in action!

Introductory

The second attempt. I first bought a laser engraver from Alfawise years ago, one that could work as a normal knife engraver (milling machine). To put it mildly, I burned myself with it. Well, not with the laser, because the one flashed after turning on, no picture or sound since. However, the knife method works, it is good.

Actually, my couple is upset with this question, she likes to get creative. I have neither the time nor the inspiration to do such things in recent years, so I admit, buying a laser engraver was not my idea.

Of course, I had to assemble it, I had to install it, and I had to experience it, and if that happened, it was reasonable to have an article out of it. You can read this now!

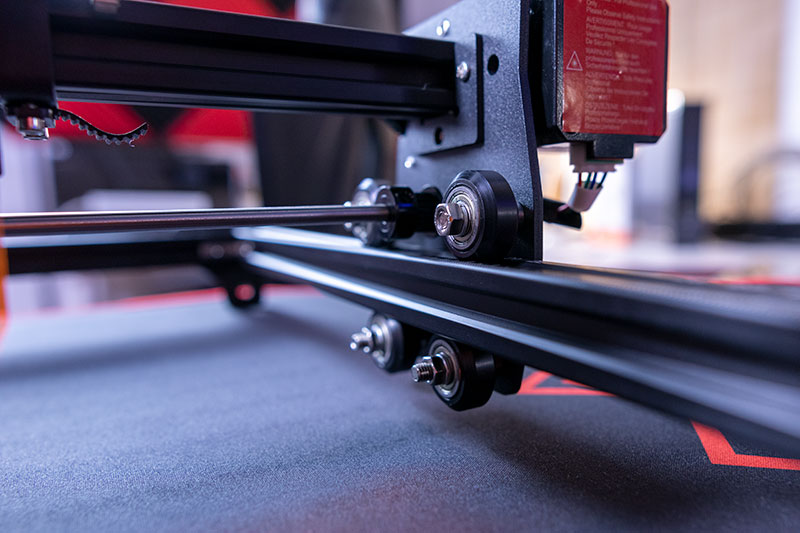

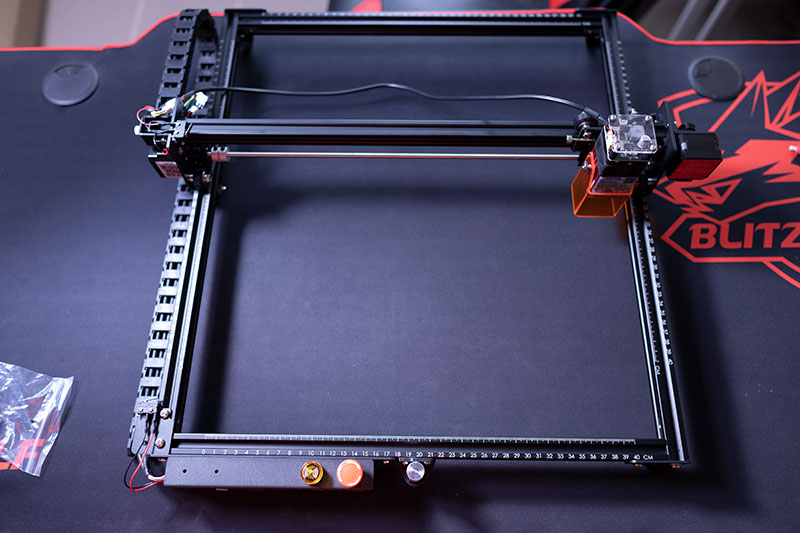

Assembly

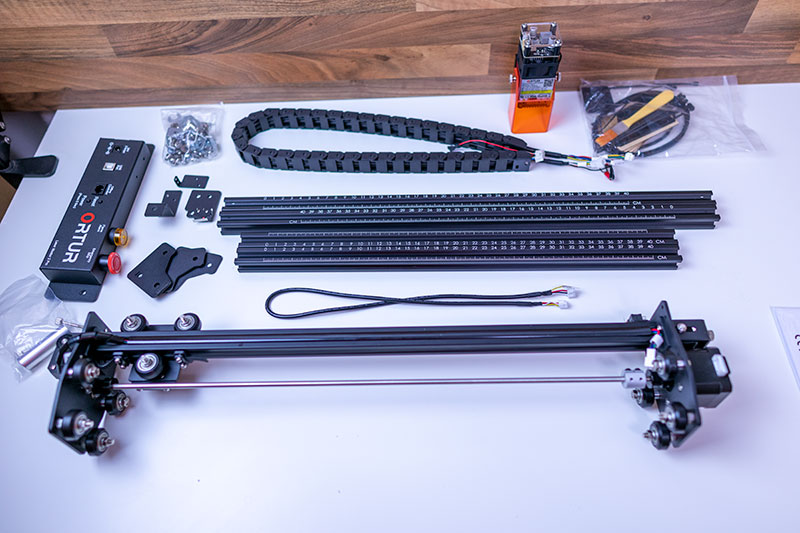

As usual, most engravers and 3D printers made by Chinese companies need to be assembled by us. Anyone who has put together something like this shouldn't have a problem, I thought, badly enough.

The Ortur Laser Master 2 Pro consists of relatively few components, there are no millions of screws next to it, so at first everything seems very simple. Maybe it was because I didn’t look for an assembly video on YouTube, but got the assembly guide out of the box and then fell for him.

Here I made the first but not the last mistake.

The enclosed guide approximates the unusable. Colorful, and all, but pretty crappy for help. I didn’t give up on any basis, I put it together, but despite the fact that there are hardly any parts, it took a long time.

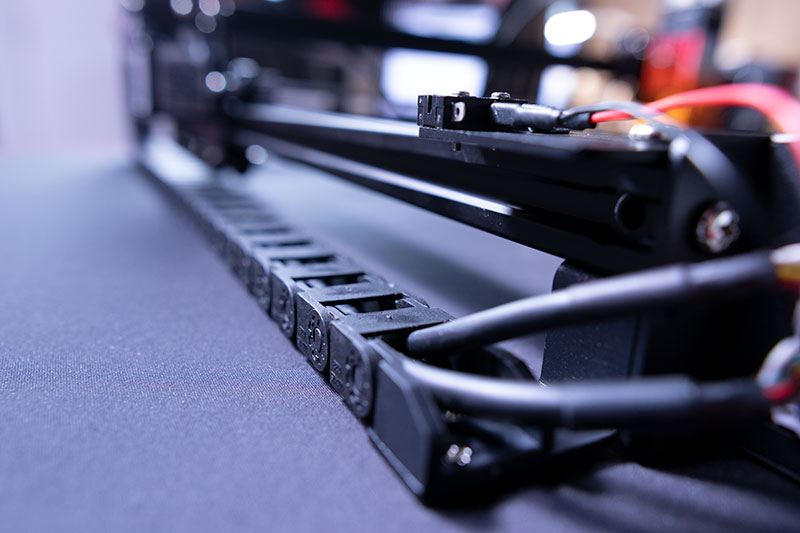

Let’s start there, it wasn’t even clear from the outset which of the sections with a centimeter scale was shorter or longer, but also which one at the corners was to be connected.

Sure, a normal resolution photo or the YouTube help already mentioned would have been enough, but I’m a rock-hard macho, no one wants to explain anything to me, I’m solving every problem out of muscle.

Anyway, I'm done, everything is in place. Specifically, just about everything because some parts that have no role are left out are not included in the assembly instructions either. I even booked to myself that despite all the attention and experience gained online, I bought a crap again.

I installed the program on my notebook, and I connected the driver to the notebook via USB, plugged in the power, and turned it on. So far so good, the new hardware has appeared in the device manager, it has got the COM3 port, it beeps, so I'm done. At least that's what I thought.

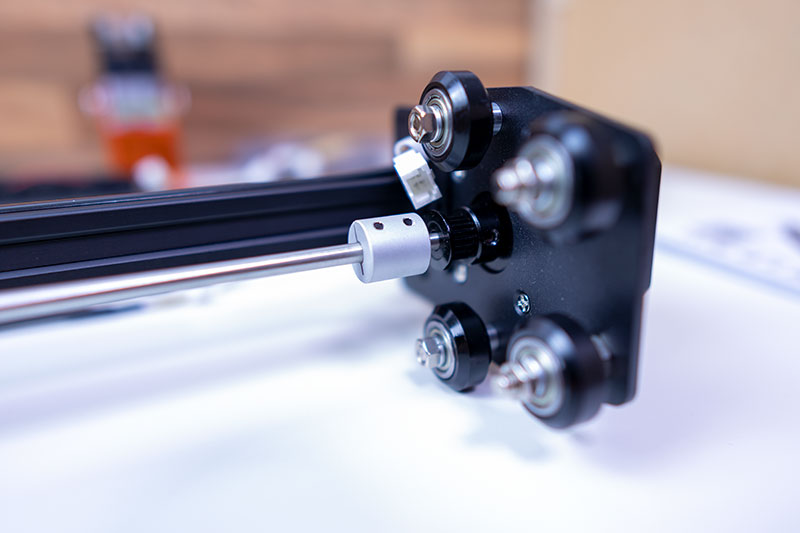

I pressed a home button in the program to get the head to the initial position. The race started to the left, then a beep, an error message. Okay. Nothing wrong. Reset, I start over, error message. That's when I started thinking about what would make the rail holding the head start, what would move it.

Although I connected the engine, it started, but it was as if something was still missing. Then the tantus fell.

There were two rack rubber bands in the package that I couldn’t find a place for. I thought I had a spare. I took out the booklet, looked for it to be installed, but it turned out that the description omitted the installation of the tapes with noble simplicity, so I’m not so stupid.

Well, that’s when I sat down in front of the computer, looking for a normal assembly video.

The tapes had a role installed, of course, as they were put in place, the error message disappeared, the rail, the head moved, everything was perfect!

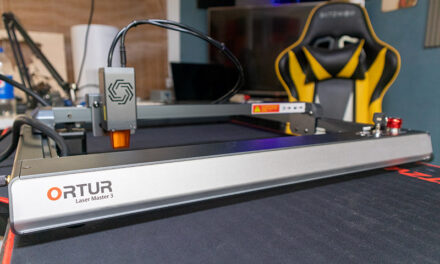

Why did I choose this?

Okay, the machine works, now let’s see why I chose the Ortur Laser Master 2 Pro!

I was sure I didn't need a cutter, Alfawise was there, it would be enough to look for a plain laser engraver. Since I didn’t understand beef for the thing, the first aspect was to be big, but cheap compared to the options.

I didn’t want the size to stop my sweetheart from creating some dick thing. Well, my expertise ended here, as my faint purple steam wasn't about what laser engraving was on.

I started reading, watching videos. It was obvious that if possible a strong head, a strong laser was needed. It was not harmless to use it, nor to be able to put material thicker than 3-4 millimeters under the head if possible.

It was also important to be able to engrave on as many different materials as possible, and I already figured it out from my own wellhead so that in addition to the engraving, the laser cutting would also go if I was already buying something.

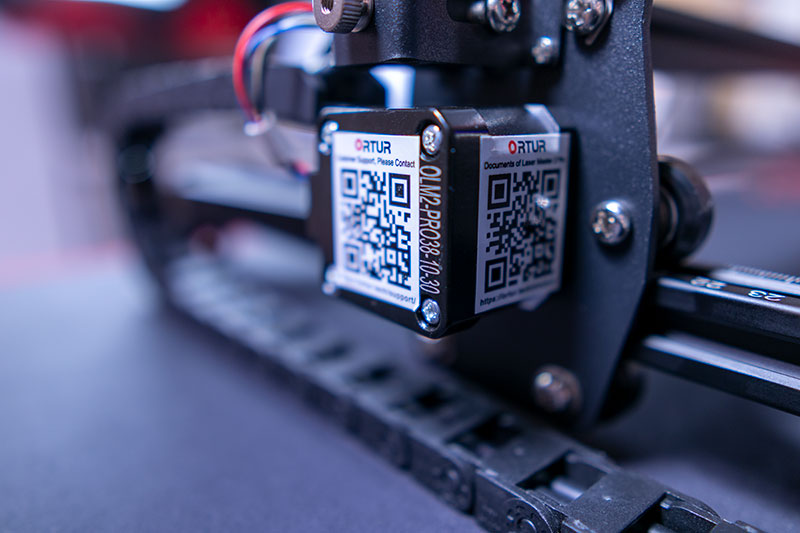

Orturt was praised in many places, including the Laser Master, and then I saw that a newer version of it, the Master 2 Pro, was already available. He looked satisfying in every way. It can be used to create large patterns up to 40 x 40 centimeters. The height of the head is adjustable, so there will be no problem with the thickness of the material, plus I only read a good deal about the new, improved laser unit.

It seemed like it was going to be perfect. I was looking for a store where an acquaintance works and of course one where there is an EU warehouse for the moth. True, it was a little more expensive than if it came from China, but it was important for it to arrive quickly.

So I bought it.

Paper form

It can come in paper form, i.e. factory data. I won't spend much time on these, in the next chapter, I'll return to 1-2 more important features when using them.

| Laser Master 2 Pro | |

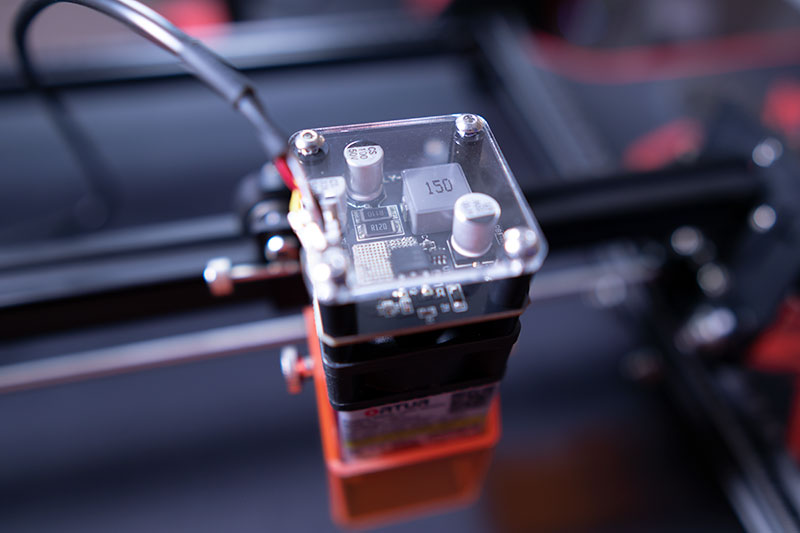

| Motherboard | OLM-MAXUP-V10 motherboard with 32-bit MCU |

| firmware | OLF-V1.5 firmware |

| Security measures | 1. Active position protection 2. Detection and limitation of exposure duration 3. Laser beam security guard 4. Flame detector 5. Emergency stop button |

| Frame materials | Aluminum + powder coated steel |

| Engines | NEMA 17 stepper motors |

| Mechanical accuracy | Y: 12,5 μm X: 12,5 μm |

| Adjustable (Default: 300 pixels / inch, approximately 0,81 pixel accuracy) | |

| Engraving area | 400mm * 400mm |

| Available laser modules | LU2-4 (2nd generation FAC, light output: 4500-5000 mw) |

| Wavelength | 445 ± 5 sq m |

| Focus | Fixed Focus, 50 mm (from heatsink to object) |

| Control mode | PWM |

| Power ratio | S0-S1,000 |

| Engraving speed | 0-10 000MM / min |

| Transmission speed | 115200 - 921600 (Default: 115200) |

| Computer operating system | Win XP, Win 7, Win 8, Win 10 (LaserGRBL) Mac and Linux (LightBurn) |

| Control software | LaserGRBL (free), LightBurn (paid software) |

| Input format | JPG, JPEG, PNG, BMP, SVG, etc. |

| Available engraving materials | Plywood, cardboard, black acrylic, leather, stainless steel, aluminum, etc. |

| Input voltage | 110V-220V (compatible) |

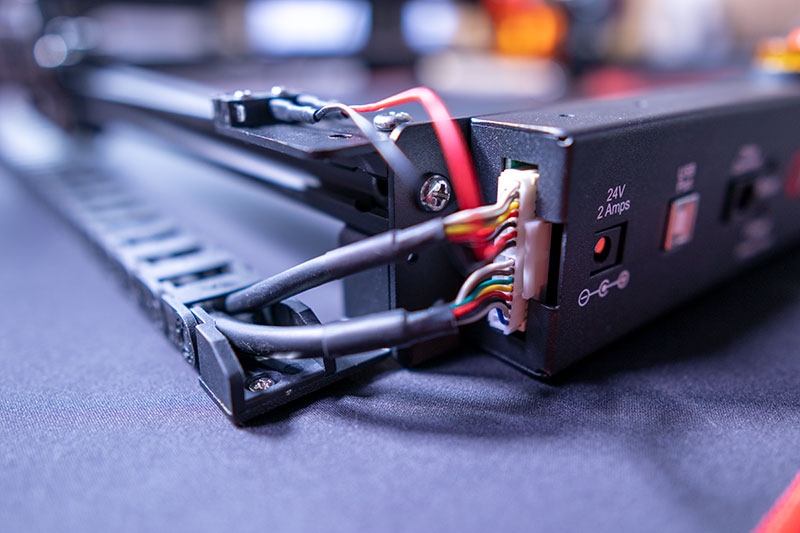

| Power supply adapter output | 24V / 2A |

| Operating temperature | -20 ℃ -50 ℃ |

Use and experience

As I wrote above, I didn’t even have a shot at what tree laser engraving is creating. In videos, things seem so simple. I put the material to be engraved under my head, load the drawing, start it, and then it’s done. Simple as a slap.

The first try confirmed it, because I immediately managed to create a graphic on the test disk next to the machine. Then I looked to the right, I looked to the left, and somehow it wasn’t real. In addition to the lines, the wood burned, and the line thickness was more than enough. So it was there, it was good, but only for the first time.

Well, that’s when I started reading more seriously about what tree this was all about, and then I started to really appreciate the capabilities of the machine. Obviously, since I didn't know until then that these were important skills.

Let’s start there, as it can be seen from the above description that this is a fixed focus machine. If it is not, you have to screw something on the bottom of the laser head while checking visually that the focus point is as small as possible. Thus, the height of the head cannot be adjusted (or at least not all of them), so the thickness of the material that can be placed under the head is limited from the outset. Okay, here too, but much less.

Focus on fixed focus heads should be adjusted with a spacer provided with the machine. Needless to say, I didn’t even look at how to use it. Why, I understand everything, that's how I was born. Or not.

For some reason, it was obvious that the spacer had to be placed between the head and the material to be engraved. The spacer is round, the head is too, given the thing. Of course, the engraving wasn't good either. Of course, I didn’t put the spacer in the right place, it should have been between the heat sink and the material to be engraved.

Then there's the accuracy. Fortunately, you can adjust the DPI number (dot per inch), as well as how many lines per millimeter to draw in horizontal, band-by-band engraving. This is good because some shades can be included in the drawing. Okay, there won't be 16 million colors, but we don't expect that from an engraver.

As I realized, head speed is also important. In the case of the Laser Master 2, the maximum value was still 3000 millimeters per minute, but with the Pro version I bought, it could be as much as 10 thousand millimeters per minute.

I didn’t know, but it’s also important when we engrave or cut. Depending on the material, what speed will be right. As it turns out, you also need to pay attention to the capacity of the laser.

It is set to 100% in the program by default, but this is not good. On the one hand, the life of the laser will not be good either, on the other hand, it will also depend on the material to be engraved, what will be the ideal value.

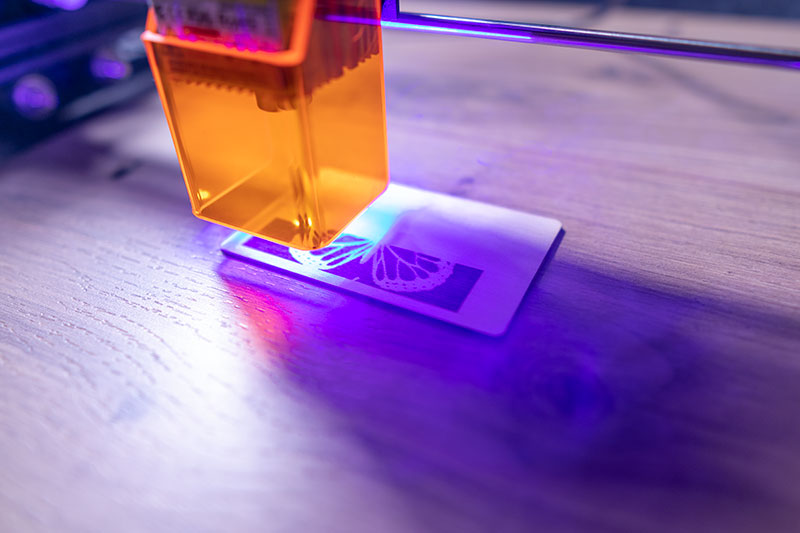

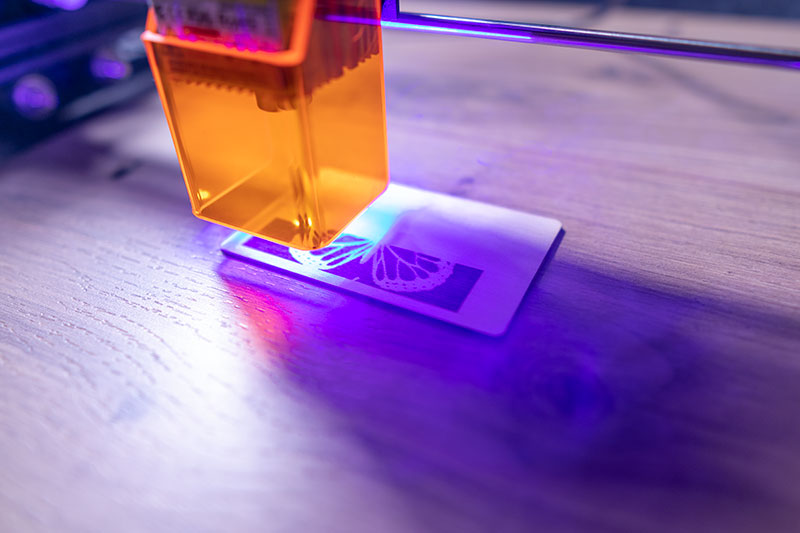

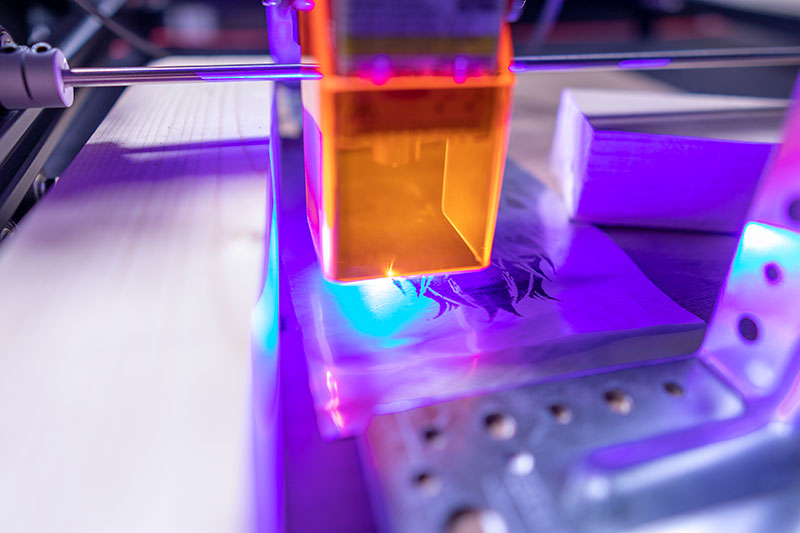

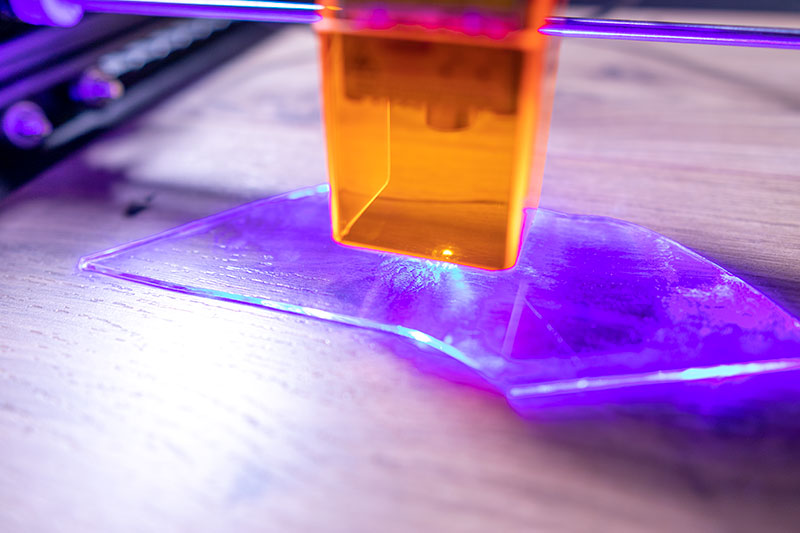

For example, for the sake of the test, I cut out a butterfly, worked with awfully thin lines, and adjusted the head precisely as well. I increased the speed of the head, took the power down to 60 percent, and set the machine to 20 passes. That is, he had to go through the lines 20 times.

It was almost perfect. The 20 passes were a bit much like that, but in retrospect I would rather have increased the speed a bit more, maybe use 55 percent. It can be seen in the picture that the thin lines have been preserved quite well anyway, even the smallest circles have been cut flawlessly, but my current experience tells us that it could be even better.

Honestly, it took a long time to test as long as I tried the Ortur Laser Master 2 Pro. If I still have an engraving for sure, it won't last that long, because I will have experience, but for a week, I skinned this machine so that I could finally form an evaluable opinion.

I engraved on glass, wood, aluminum, cut plywood, and tried to cut XPS sheet as well, but the latter isn’t going yet, I won’t even show it. True, these are usually cut with a heating wire, but I have not yet given up that you will succeed with this machine.

Experience, use

Well, I’ve described a lot of things in the previous chapter, but there are more!

We need to completely differentiate between the settings for cutting and engraving. For example, the focus when engraving should be set to the surface of the material to be engraved. However, when cutting, it is better to adjust this to the center of the thickness of the material to be cut.

For example, if you are cutting from a standard 3 millimeter plywood, it is one and a half millimeters from the table top, or vice versa, one and a half millimeters below the surface of the material.

This is because we get the best results in focus, but it is no longer fortunate to adjust the head while cutting because the machine will pass through the edges to be cut several times. In this case, it is enough if the head moves a little and the cut line also slips.

If we focus on the center of the material, there will be enough margin both down and up to make the cut nice.

It is also very important how the drawing is used for engraving. If we also want to include shades of gray in the engraved graphics, we need to use line-by-line drawing, but if we don’t need that, we just want nice thin and accurate outlines, we need vector drawing.

The software called LaserGRBL, recommended next to the machine, solves this with one click, ie we will be able to form a vector drawing even from grayscale graphics. In connection with the software, it is important to mention that Hungarian is also among the available languages.

Not only this software can be used for the machine, but also the paid, much more serious LightBurn. It has a short trial period until it can be used for free.

It is also important that although it was obvious to me, the engraving is not started by the machine from the zero point. We can do that by moving the car to the starting point, but this will be important if we want to take advantage of the maximum size to be engraved.

In other cases, for smaller materials and drawings, we can manually move the car, the head, and where we push it will be the zero point at the beginning of the drawing.

If you want to cut, always use a vector drawing. In this case, the head follows the lines to be cut, cutting the material evenly and nicely. If you choose to line-by-line or, more precisely, line-by-line mapping, the cut will not be nice because at the edges, when the head returns, it stops for a fraction of a second and the laser burns the material.

It is usually good not to engrave on the tabletop smoothly, but to put some extra material under the machine or at least under the work material so as not to burn the table apart. This is most recommended in the early days. I used a harder laminate floor for this purpose. I snapped 2-3 leftovers together, this became the washer.

If you are experienced or you may still need a washer, even in two cases. There may be more, but so far these two have struck me.

One, of course, is cutting. Until you experience things, you don’t know how many passes, that is, how many turns it takes for the laser to cut through the material. You can't check this on the fly because you can't take the disc to be cut to see if it has been cut by the laser. You can take it more accurately, but you don't put it back a millimeter exactly, that's for sure.

So, in that case, it’s better to set more passes, and it doesn’t hurt to not cut the table top if you’ve set too many.

The other is engraving on glass. I didn't even do it very well. The result shows that it will really go, but I still have to experiment with it to make it really nice.

The point, however, is not this, but that the laser will pass through the glass and burn the surface beneath it as well. It's okay if it's not the tabletop.

If you have glass. I don’t want to buy the glass spinner for the machine yet because I’m not sure we’ll need it. However, it is already good that there is such a thing!

What is a glass turner? Well, a motorized structure on which, for example, glasses and wine bottles can be placed. If we use this, the machine rotates the bottle or glass nicely, slowly under the head, so we can also make nice “engravings” on a curved glass surface.

Some safety features are also built into the machine. The first thing to keep in mind is the emergency stop button. All we have to do is click on it and the work will stop. It can be released by rotation.

In addition, there is a sensor fire, but the machine will also shut down if you accidentally push or disconnect from the computer.

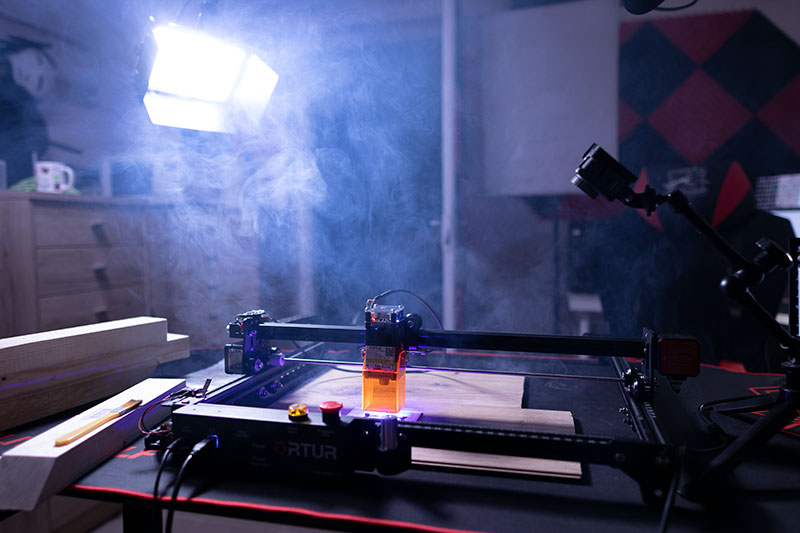

By the end, there are two more pieces of good advice, or so to speak, a rule to follow. It’s no coincidence that Ortur also makes a closed box next to its engravers, something we can attach to an extractor.

When you engrave or cut wood, only smoke is produced. If you have a plywood, the vapor of the glue will already be in the air, and if you work with plastic, it will be all that is carcinogenic. So the bottom line is: Only use the machine in a well-ventilated room if you can do it even under a canopy. If you are ventilated indoors or by all means, just to protect your own health!

The second important thing is to WEAR GLASSES! It is not accidentally added to the machine, the laser light can damage the cornea, in extreme cases it can also cause blindness. Even in glasses, it is not recommended to monitor the work process for an extended period of time. Look at it, check it out and let it work!

Summary

The career of the Ortur Laser Master 2 Pro did not start well for me, the torments of assembly were worn out. I note this is largely due to my own stupidity, Don’t be lamas, search YouTube for a good little assembly video, it’s going to be a breeze.

However, because of the assembly instructions, the company has a huge black point.

As the article shows, laser engraving is not such an easy task. The fact that you will need to add a good machine. For me, half by accident, I managed to do good. I note, for the most part, this was really my luck, because I only realized the essence and benefits of a lot of abilities during use.

The point is that this is not an Alfawise, Ortur is known and recognized among the engraving companies, so that's why it's worth choosing. (yeah, and because i immediately found another firmware for it, so presumably the functionality will also fix the bugs as well).

For now, I have no idea what kind of creations are going to be made, as I wrote I didn’t buy the machine for myself. Of course, it is natural that my imagination was shaken during the experimentation, so for example I am almost sure that I will make some more interesting 3D puzzles and also cut out unique puzzle games for my sons.

So I don’t even have the engraving that I really like in it, but the possibility of laser cutting. All I have to do is look for a cheap 3mm record.

I know my couple would like to make ornaments on the wall, engrave on wood, make a Christmas tree ornament and it is almost certain that some ornate box tops for gift box wines will be made in the near future. So, use will only be hampered by our imagination.

In the end the price. The Ortur Laser Master 2 Pro is not one of the cheaper machines, which is no wonder given its expertise. Of course, the price is only relative, as I found the older Laser Master 2 at a price well above 130 thousand forints, compared to the Ortur Laser Master 2 Pro coupon, which can be purchased from an EU warehouse for less than 120 thousand forints.

Obviously, there are also cheaper structures, so tastes and slaps on who chooses which one. I preferred to gather a little for it and buy the more serious one so that we would not feel little knowledge later. That is, do not grow out of months.

If you like it, use the coupon code MA2PRO at the link below and when you put it in the cart you will check that the shipment starts from EU so that it arrives to you quickly.

Buy here:

Ortur Laser Master 2 Pro laser engraver

If ordering from a Chinese warehouse is not a problem, you can also receive gifts next to the machine with another option here:

Ortur Laser Master 2 Pro + gifts

Related topics:

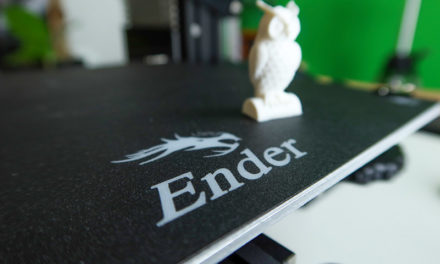

We tried it - Creality Ender 3, a cool 3D printer for the price of a better inkjet

Learning is important with a cheap 3D printer, not just for kids