3D printer from the future - Biqu Hurakan test

3D printing at home will no longer surprise anyone. 10-15 years ago, of course, the situation was completely different, but nowadays the simpler types of 3D printers hardly cost more than a traditional, higher-quality ink printer.

contents show

Of course, I also made a video of the printer, click and watch it in action in my video presentation. If you liked it, subscribe to my channel!

I myself have been using a 3D printer at home for years, but stay with us, to this day I am only scratching the surface of the possibilities. At one point, it almost sucked me in, I started creating 3D models, e.g. from Google Maps data, but then I had to realize that this hobby can wait until I retire. I just don't have enough time for it.

So I stayed with the simple prints that are available online. It's true, I also learned a lot in the process, and I had to realize that 3D printing, if we want to do it well, is not an easy task.

You need to know the materials used for printing, and you need to be able to properly set the heat values for the bed and the nozzle. It does not matter at what temperature and speed we make the raft (this will be the object to be printed), nor at what temperature and speed we print the workpiece after making the raft. In fact, it is not irrelevant whether we need to print a raft at all.

And these questions are really just the surface, the most basic knowledge you need to be able to make more normal prints.

In this article, however, I do not want to introduce you to a simple 3D printer, but one that, in my opinion, takes weeks or even months to use normally, if you deal with the subject very intensively.

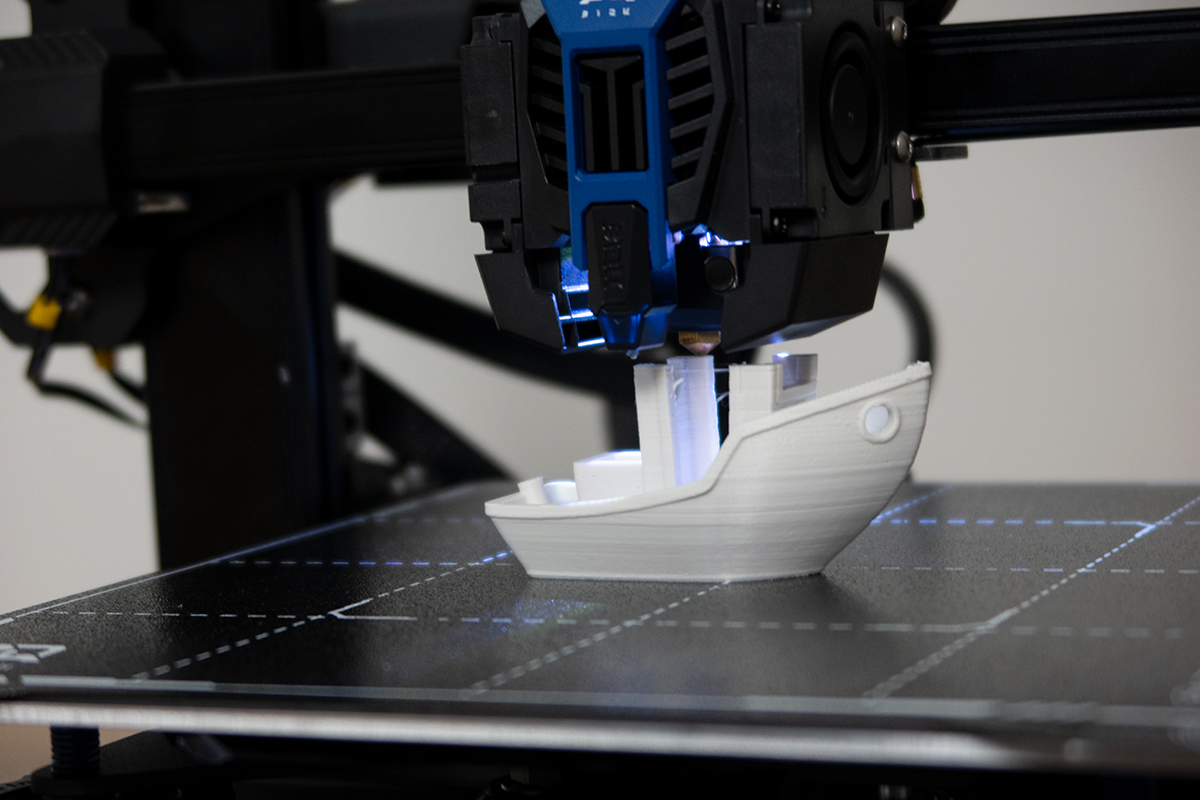

I was crazy that it arrived, I was glad that I could try it, I was glad that I managed to print something with it.

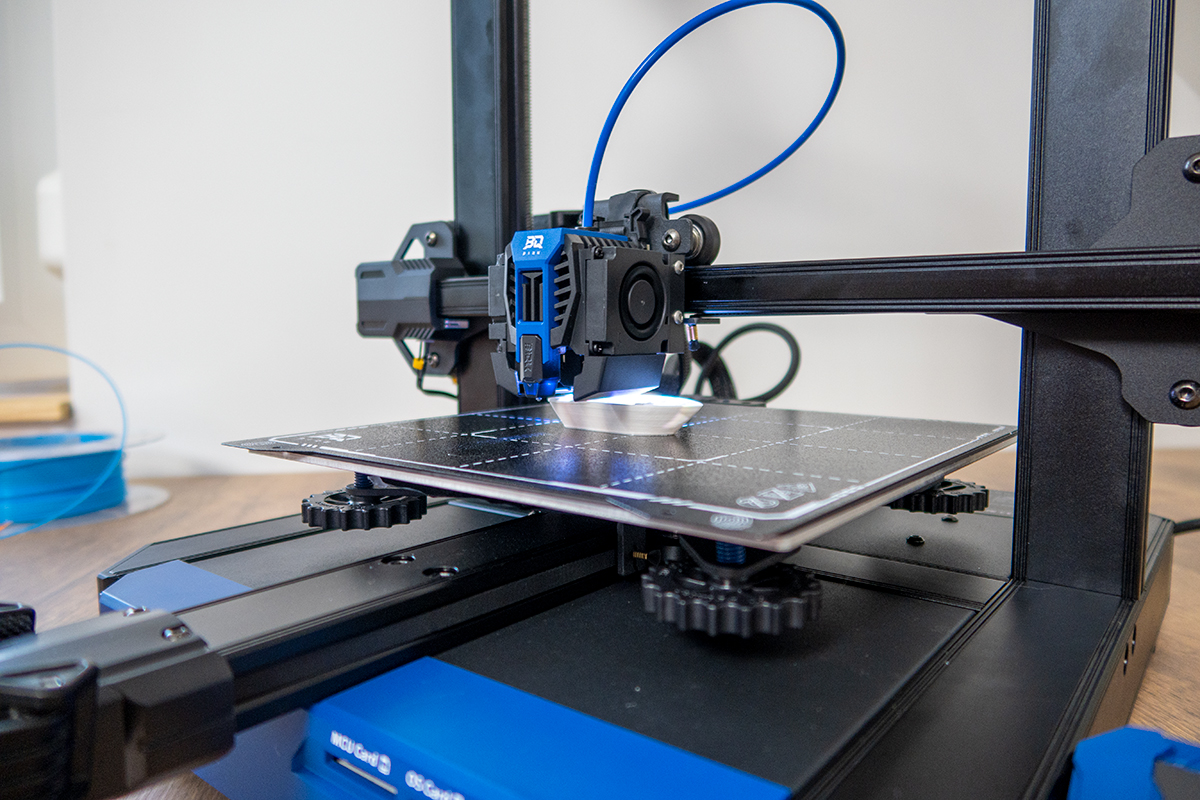

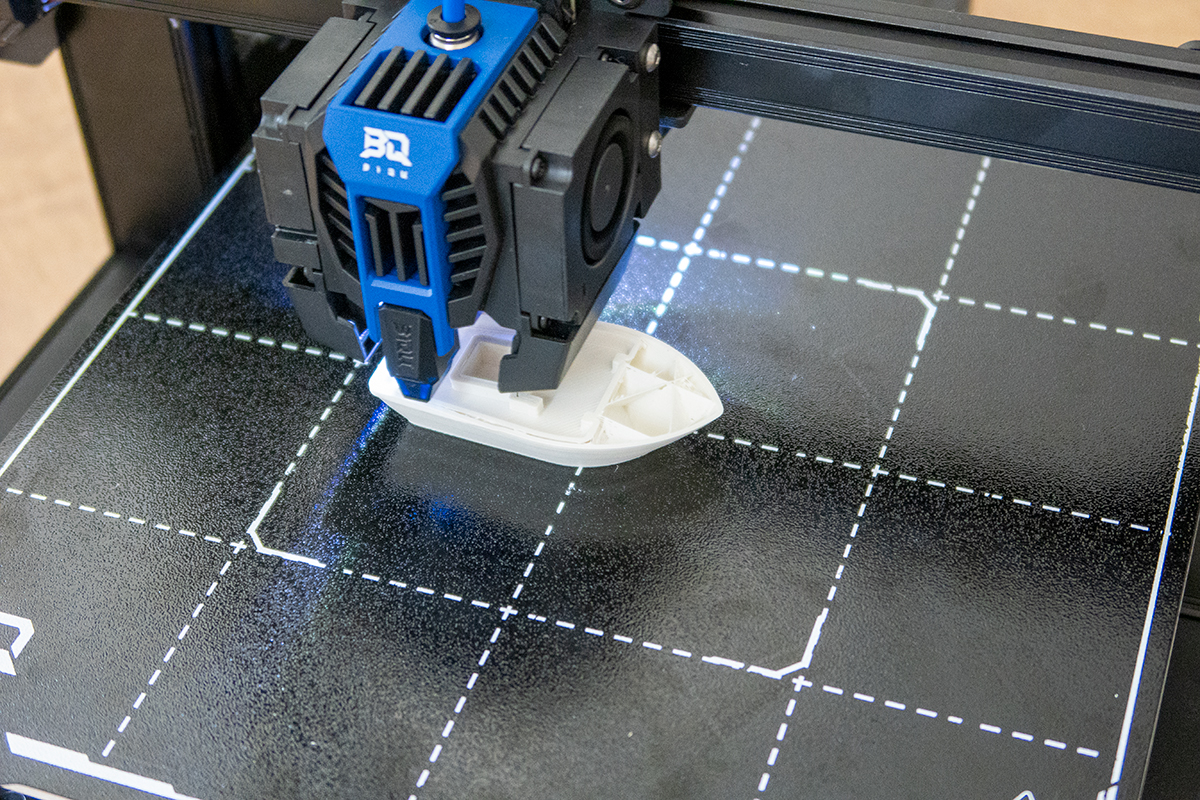

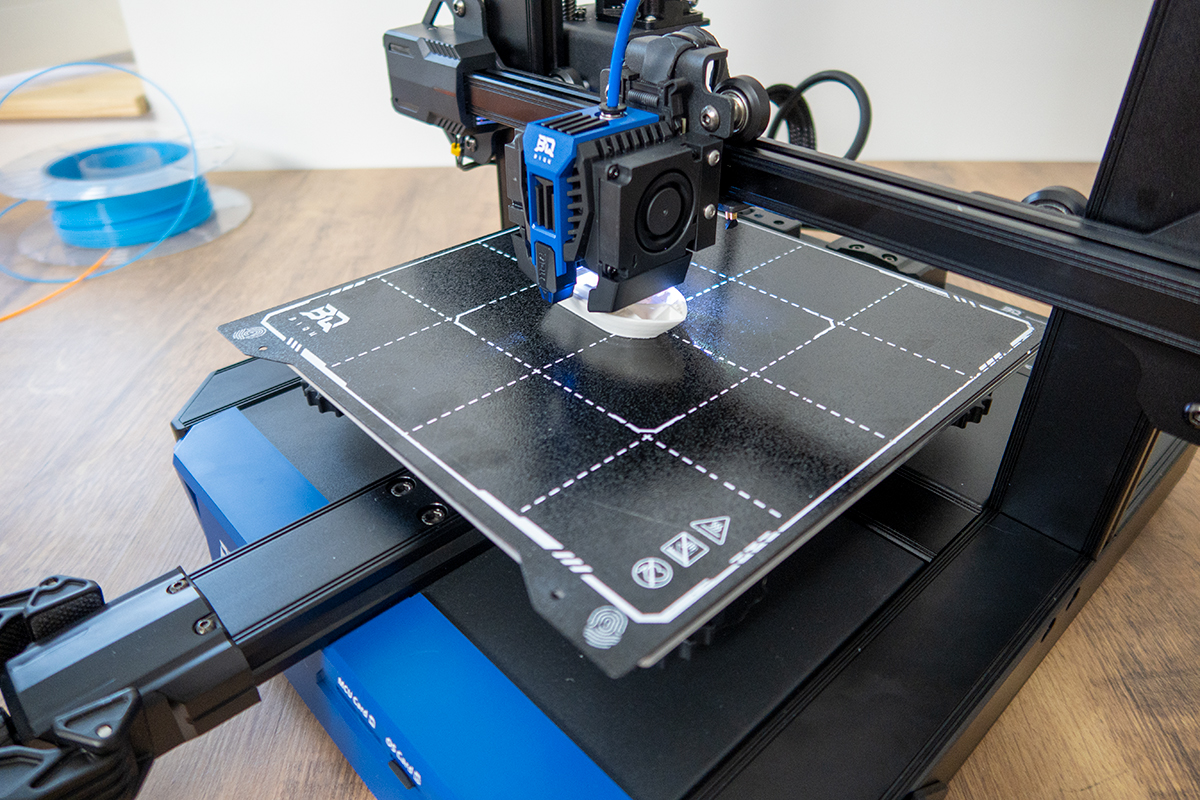

The Biqu Hurakan is not an ordinary printer, even if it seems so at first glance. From the outside, it looks very similar to my own printers. Of course, there are differences here and there, but they are not significant.

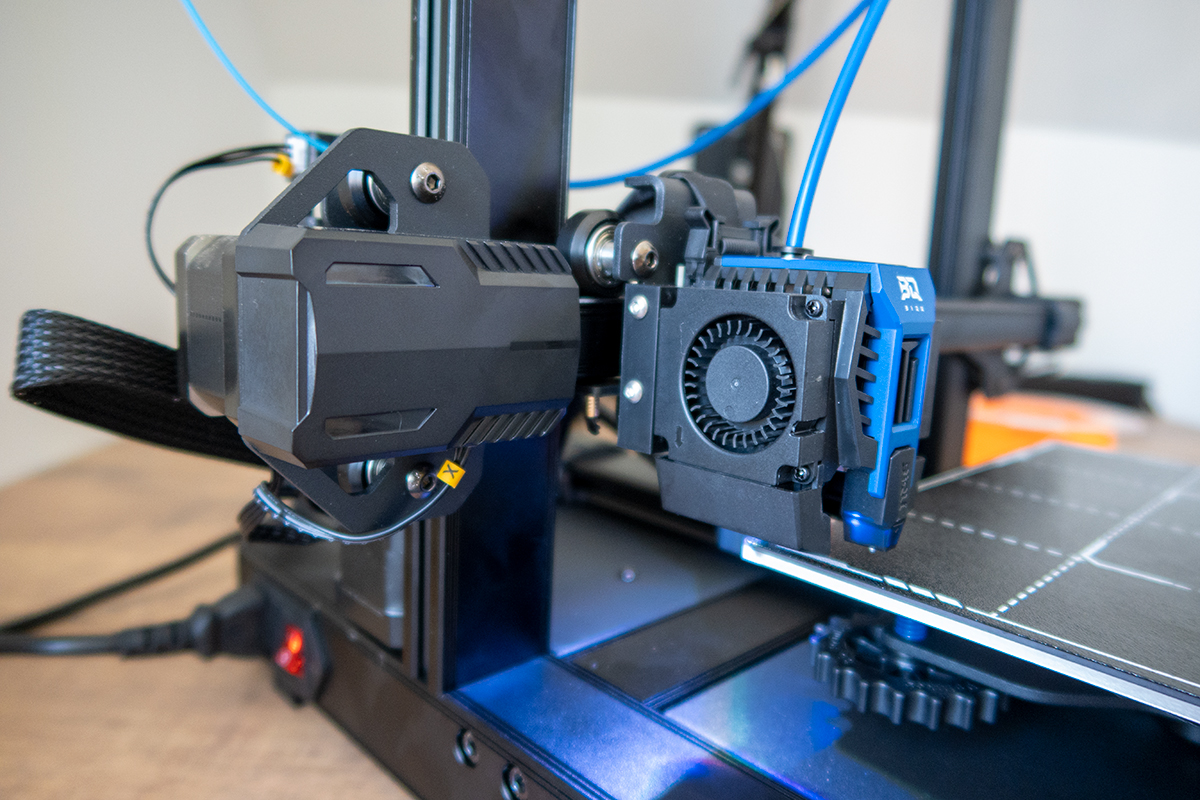

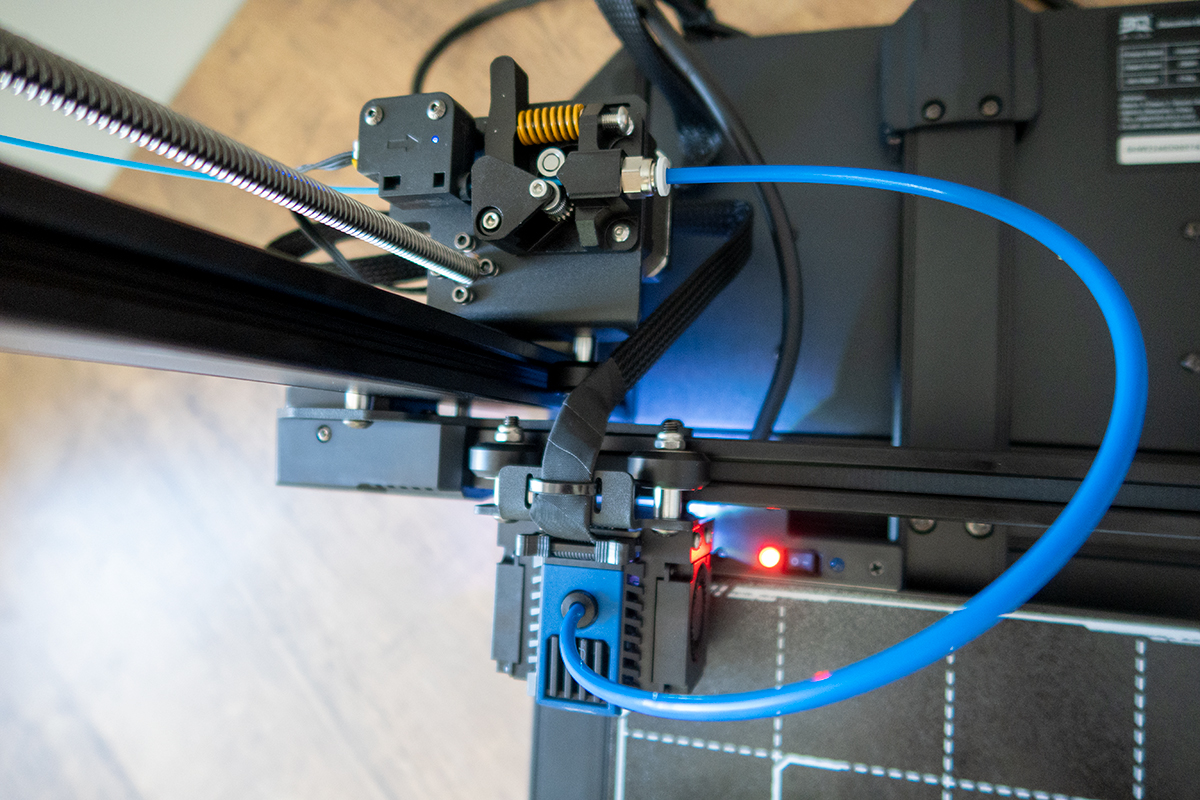

The extruder and the head are not integrated, like cheaper printers, but there is a filament sensor, for example, which allows us to use the filament to the last centimeter, because if it runs out, we can easily load the next roll.

The special good news is that this sensor is placed on the extruder, so the filament arrives at a normal angle to the motor that moves it, it does not break.

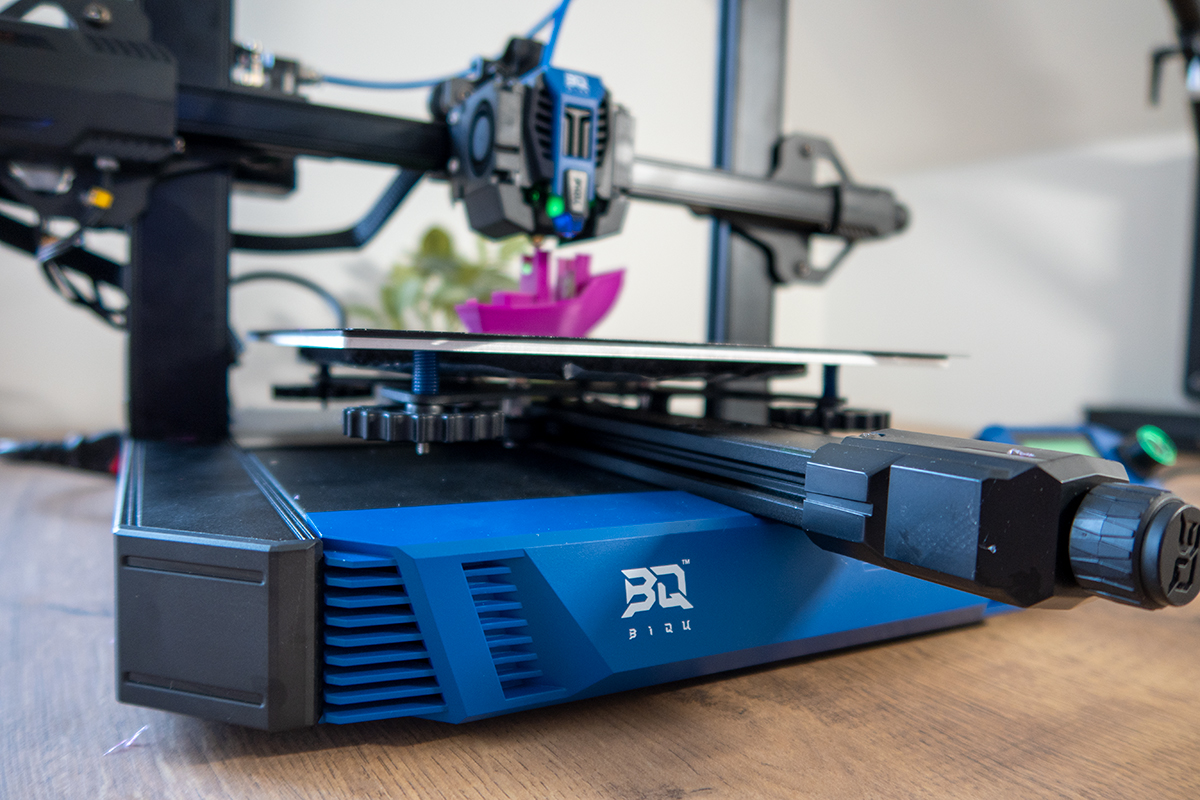

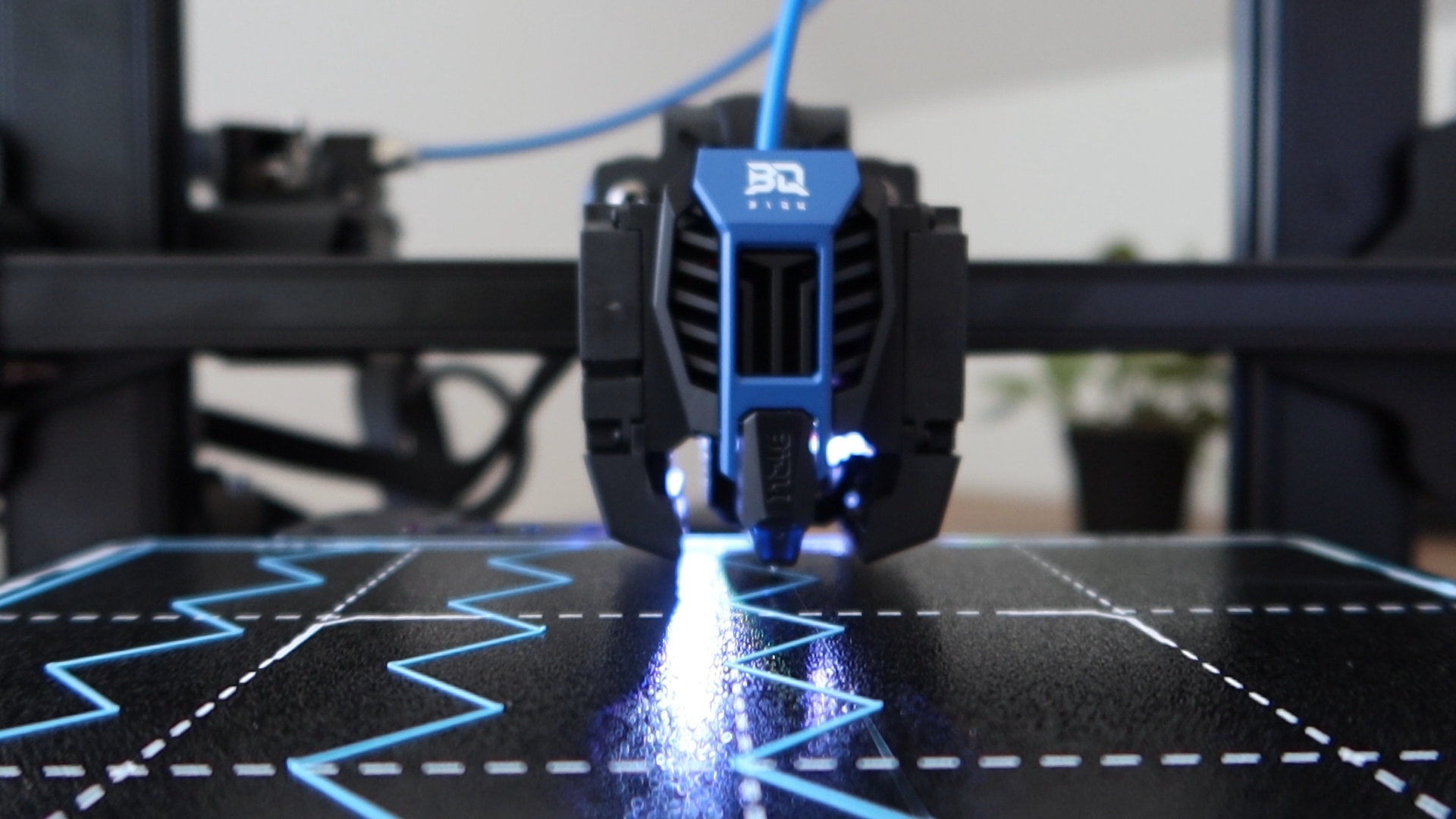

There are also other interesting things, some of them are just interesting, some of them are downright useful. First of all, a good example is that the LED that illuminates the workpiece is RGB, so we can determine what color it should light up. A good example of the latter is the bed, which can be heated in two stages. If the workpiece is small, it is enough to heat the middle area (~100 watts), if it is large, we can heat the entire tray (~240 watts).

At this last point, let's get a little carried away! It is interesting that the size of the heated surface can be changed with a small toggle switch, however, as I observed, even if we switch to a lower power, the outside of the bed also heats up, and much more strongly than I would expect from heat conduction. In other words, it is suspicious that only the heating output can be switched with the switch. Fortunately, this does not affect the operation, the internal 10 x 10 cm surface reaches the desired temperature, which means that the saving works. For smaller items, we save approx. 140 watts with this clever solution.

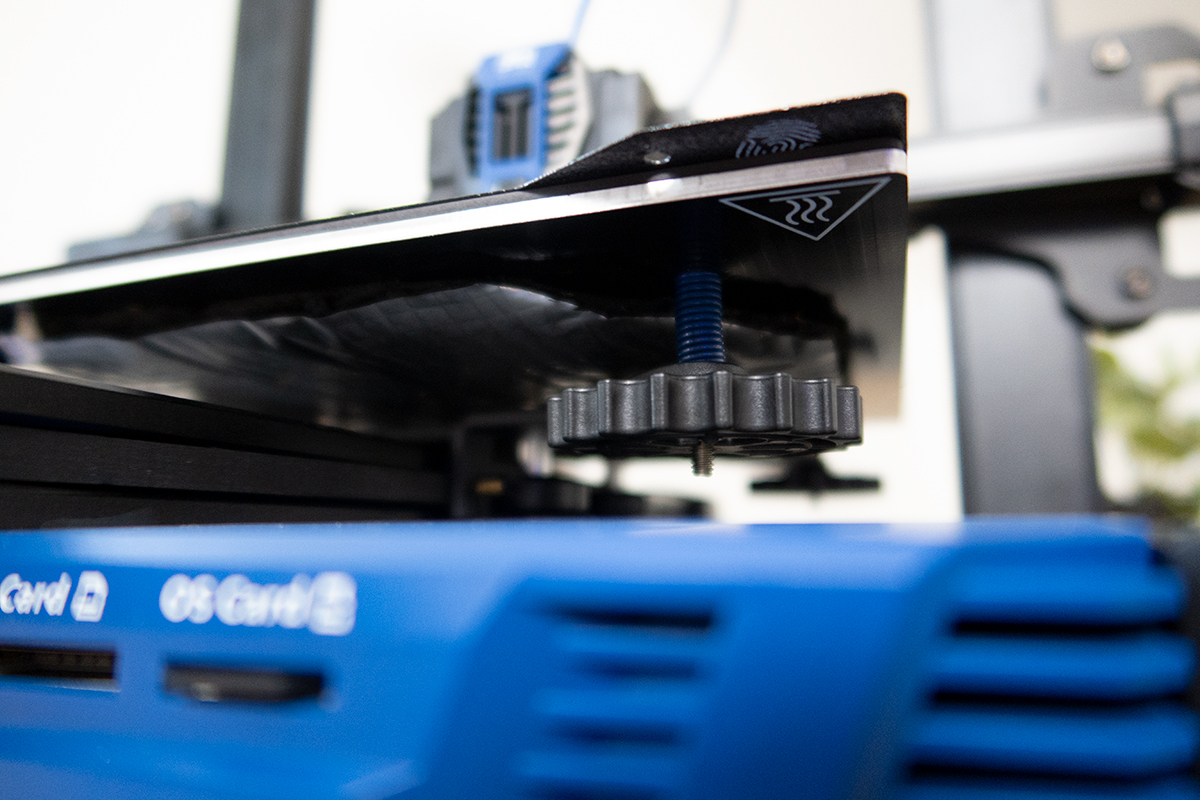

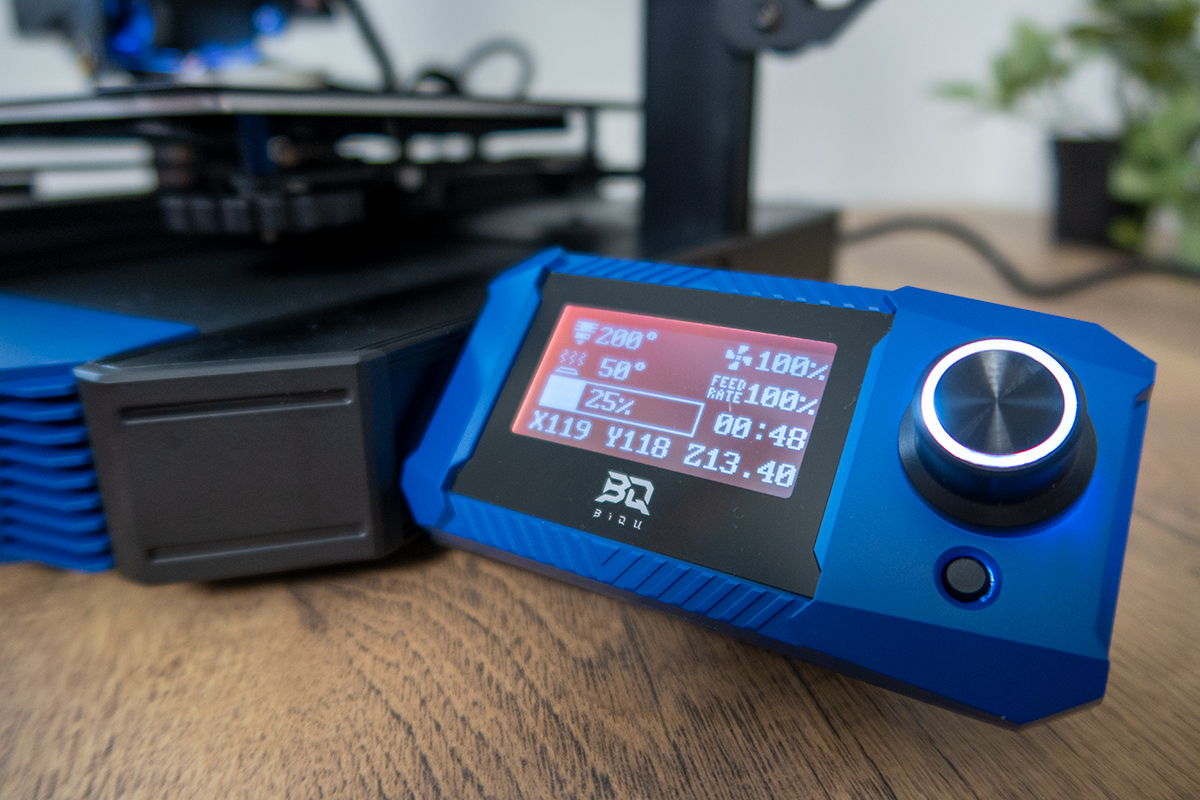

In addition to these, of course, there is the magnetic bed on which the slide is placed, there is the automatic table leveling, the display, but I can also mention the web-based, browser-based interface as a real interesting thing, but this is already slipping into the slightly more serious things, so I'll come back to that later!

I think it is clear from the title of the article that the Biqu Hurakan offers much more than a traditional printer, because the soul of this machine is the Klipper firmware. The machines that work with Klipper are already among the more professional structures, which is why the prices are much higher, but at Biqu they decided to build the right hardware into a cheaper machine and of course you get the right software.

There is currently only one other Klipper machine in this budget category, the FLSUN V400, which is well over double the price of the Hurakan, and can still be called cheap.

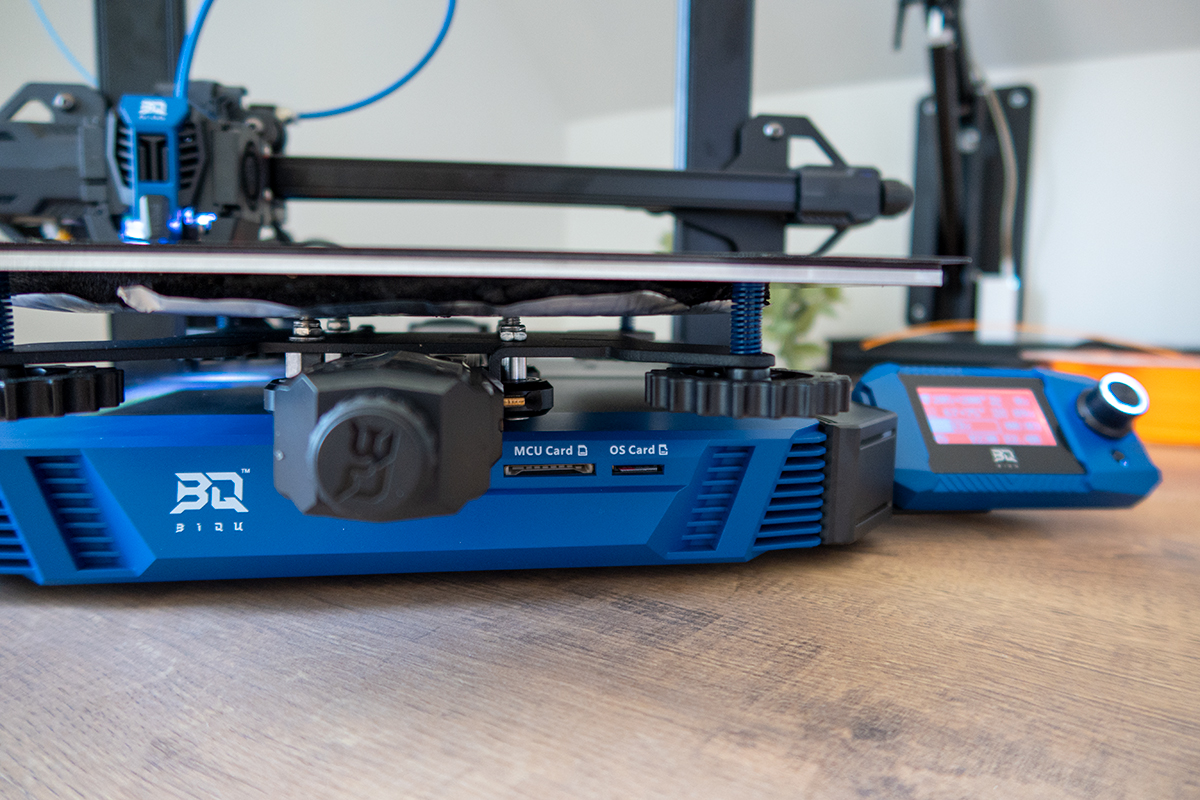

To be able to run Klipper on a computer, not much is needed, "only" it is enough to install a computer capable of running Linux. This can be of several types, Biqu runs the system on a self-developed hardware, with which they managed to achieve a very low initial cost. This hardware is also available separately and can be purchased if anyone is interested in it.

However, don't make them suspect some crazy powerful hardware, it would be unnecessary here. An Allwinner H616 SoC, a Mali G31 MP2 GPU with OpenGL3.2 support and 512 MB DDR3 RAM are enough. This is enough to run the system and allow users to access, manage and monitor the system from a desktop via the Mainsail UI

It's time to return to the browser interface, which we now know is called Mainsail UI.

This software is essentially a complete remote monitoring software, since we can control the machine from anywhere where there is some kind of internet access, and of course our home network is also prepared for the machine to be visible on the net.

You can start and stop printing, adjust the settings, level the bed, upload new G-Code files, and even if you connect a plain web camera to one of the rear USB ports, you can monitor the progress of the print job via the camera's image on the browser interface. too.

Of course, there are other functions in addition to these, for example, it is possible to adjust the color of the above-mentioned RGB lighting or to update the software.

The program and the user interface are perfectly transparent, and it knows many languages, including Hungarian. Of course, I think that this will only be important in the first time, because the documentation and a lot of tutorials (a really crazy amount) are available in English, so it really bothers me if a menu is referred to by its English name in a description, I have to figure out that I wonder what the name can be on the Hungarian interface.

Let's go back to the Hurakan, because it has a few more pleasant surprises in store! Examples include the ultra-quiet TMC2209 stepper motors, which really work almost silently. We get two-fan cooling for the print head, which effectively cools the printing material back. The belt tensioners are very easy and easy to use, so we no longer have to play around with a wrench, we can adjust the tension of the ribbed belts very finely by hand.

Among the advantages, the manufacturer highlights the sensor used for automatic bed adjustment. This is located at the front of the print head, the stuff is said to be only six grams, and again, according to the manufacturer's data, it can be capable of 10 million detections without error. Let's say, I think it means a lot that the sensor's spike is not crappy plastic, like in cheap machines.

What did you not like?

The first is that the Z axis has no upper anchor point. It's like, to put it mildly... Well, I'd rather not say anything. I'm not saying that it affected anything for me, but I know that in the long term, the lack of fixation is important due to wear. Let's say, if I saw correctly, you can get such a mount separately from the manufacturer.

The other is the placement of the memory card containing the operating system. It's right where we normally plug G-Code cards into the printers. Of course, I didn't forget about it, I didn't mix it up during the test, but they could have found a better place for this card if it already has the operating system on it and if it is no longer allowed to pull it out during operation.

The third, which was more of a surprise, is that the system wants to start quite slowly. I already thought there was a problem, but then it suddenly loaded and went smoothly.

Well, approx. that's all bad, I think it's digestible!

Well, how is it used?

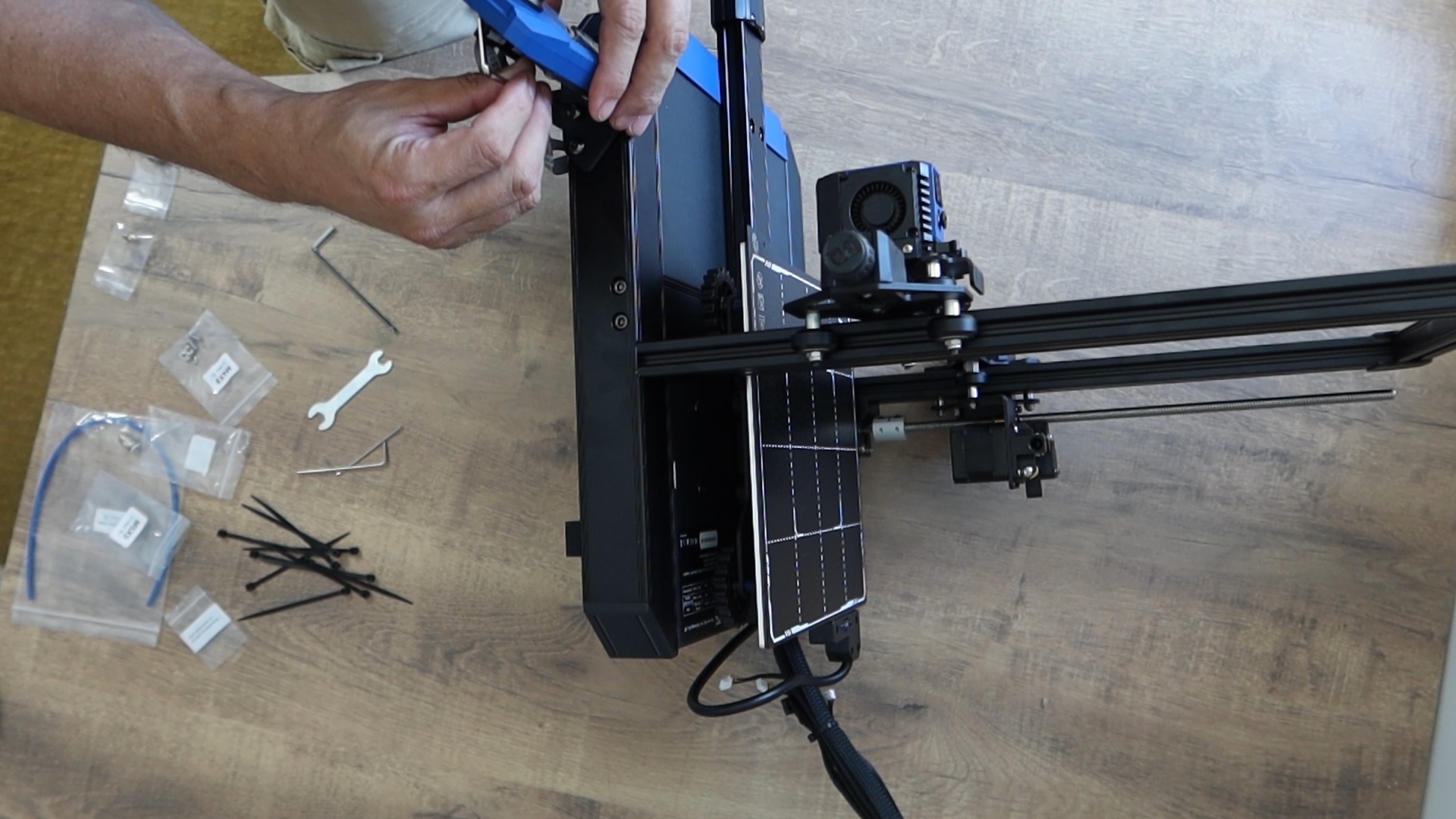

Assembly is not crazy, about 10 minutes. It says a lot about the fact that we get a total of 8 screws, of which 4 hold the frame, two the display and two the filament holder. That's it.

Regarding the installation, the routing of the cables is not very convincing. This didn't cause any problems either, but the whips touch this and that, and if someone uses the machine for years, it is not impossible that the insulation on the wires wears out. So, you have to pay attention to that.

When the installation is complete, all you have to do is to edit the cfg file on the card containing the operating system, enter the name of the WiFi to which the machine must connect, and enter the password. Again, that's all, you plug the card into the machine, start the machine, look for the IP address it received on the display. You enter this address in the address bar of the browser, and the user interface will pop up, and you can start working!

Thanks to the Klipper, we can also carry out operations such as increasing pressure and setting the linear advance during adjustment and calibration. Increasing the pressure, for example, does not require special training or special tools, we do not even need to compile a kernel, so the stunt is simplified, to put it mildly.

If you want to achieve further refinement, you can purchase an accelerometer for the machine, which you can use to eliminate, for example, surface irregularities caused by vibrations.

Basically, however, it can definitely be said that we don't need magic or an accelerometer for usable prints. After minimal adjustment (tension of belts and rollers, for example), better prints can be made with the machine than average, cheap printers.

It is true that although the speed of the machine compared to a traditional Marlin printer is referred to in many places, it is part of the whole truth that the quality will deteriorate as the speed increases. Overall, it can be said that slightly finer works can be produced at the same speed, but this is not a crazy difference.

Of course, if we save 10 percent of time on a 12-10 hour print, that is not enough!

Summary

Do I recommend buying the Biqu Huracán? Definitely yes, since it is competitive in price with the Marlin machines, but it has the advantage provided by the Klipper. You can buy a lot of accessories for it, with which you can already reach a semi-professional level.

So, in addition to the fact that the Hurakan is a very capable printer, since it knows everything from automatic bed leveling to the filament sensor that we expect from a machine of this category, there are also the "smaller" attentions, such as the two-step switchable bed heating or the RGB that illuminates the workpiece LEDs.

Of course, these are obviously not the greatest virtues of the Hurakan, but the Klipper and Mainsail UI, which enable operation via the home network, free you from the G-Code files dragged on the memory card, and of course there are other options provided by the Klipper, as long as you have enough time. , your patience and knowledge to learn everything and exploit the potential of Huarakan.

Unfortunately, I didn't have much time for this, at least not enough to properly dig into the topic. As I wrote, maybe when I retire.

However, if you feel the determination in yourself, then consider buying the Hurakan running Klipper instead of a normal, simple 3D printer, I think you won't be disappointed, and you'll find a hobby that will keep you busy for years.

So, up to Klipper!

Let's see how much that is!

The machine can be ordered from a Czech warehouse. Of course, I also asked for a coupon so that you could buy it a little cheaper (roughly HUF 8000) for a few days after the publication of the article. This means that a BG93fe16 with a coupon code, the price will be ~ HUF 93, on the link below: