The new generation has arrived - Ortur Y axis glass turning test

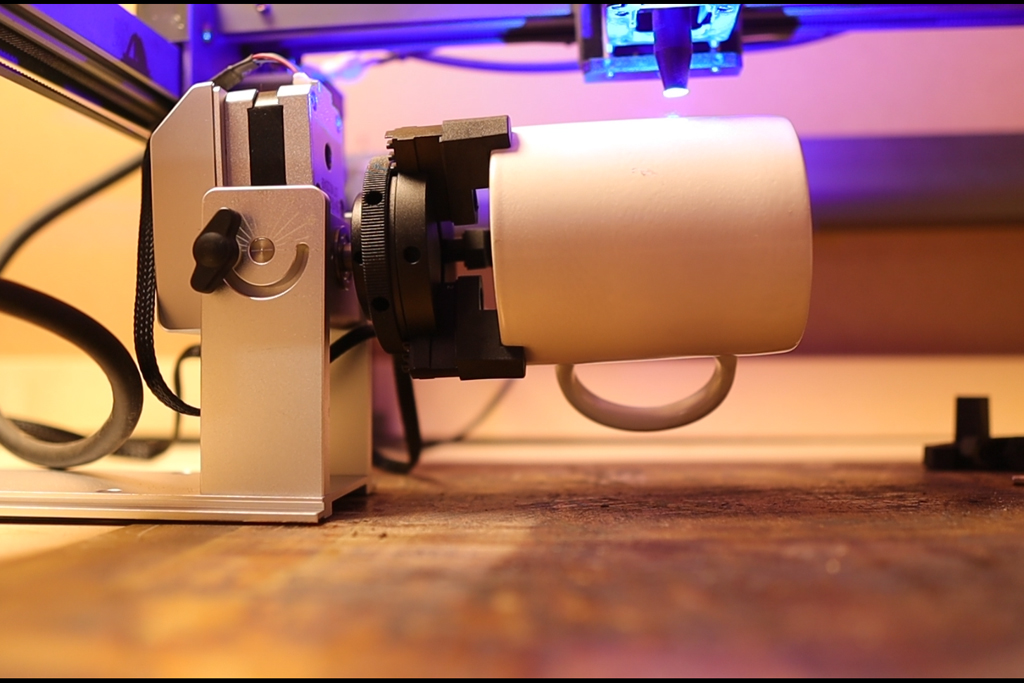

Finally, I can engrave not only on simple glasses and wine bottles!

Check out the unboxing and the first tests!

contents show

Introductory

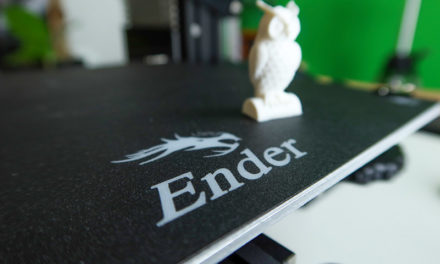

Those who are in my Facebook group (almost 17) know that I have found a serious hobby for myself in laser cutting and engraving. You can create wonderful things with the help of the laser, and here the saying is really true, the only limit in creation is the imagination.

I have already engraved on quite a few things, from wood to glass to leather, steel and even stone. I also have a glass rotator so that I can make pictures on wine bottles and glasses, but to be honest, I haven't used it much. The challenge soon ran out and the task was quite monotonous, so after a while I put the camera away and it only came out when someone asked me to make a label on a wine bottle.

The reason for this lack of interest was clearly the glass spinner!

Not because it was bad, there was nothing wrong with it, in fact, it is a very reliable piece. The reason was that it was really only possible to work with glass objects of the simplest shape, simple bottles and glasses.

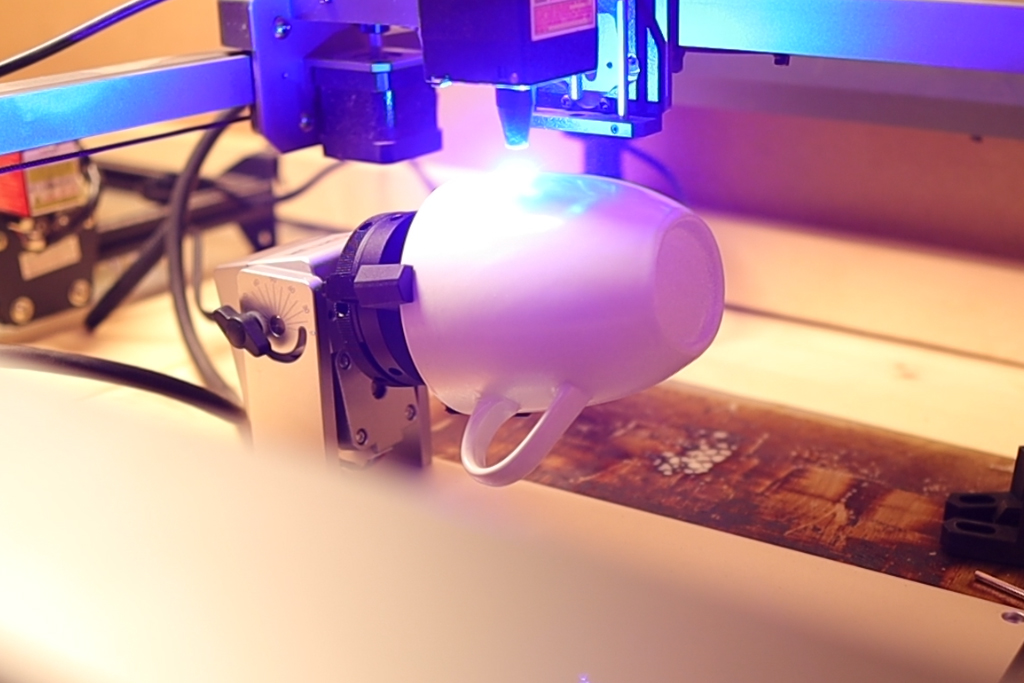

If the glass was a bit hollow, if a mug had a handle (not rare...) the stunt was already over, I couldn't do anything with it. However, in the meantime, Ortur launched a new camera, which roughly widens my options. This is what I will present to you in this article!

Packaging and accessories

The box is of the usual quality from Ortur, with thick, beautiful prints. We get the manufacturer's colors, i.e. red and black. On the top is the camera itself and some inscriptions, and on one side there is a little taste of what adapters we will be able to work with.

Opening the lid, we can see how careful the packaging is, but this is to be expected from a manufacturer of this caliber. The accessories and parts are well separated from each other, with thick impact protection.

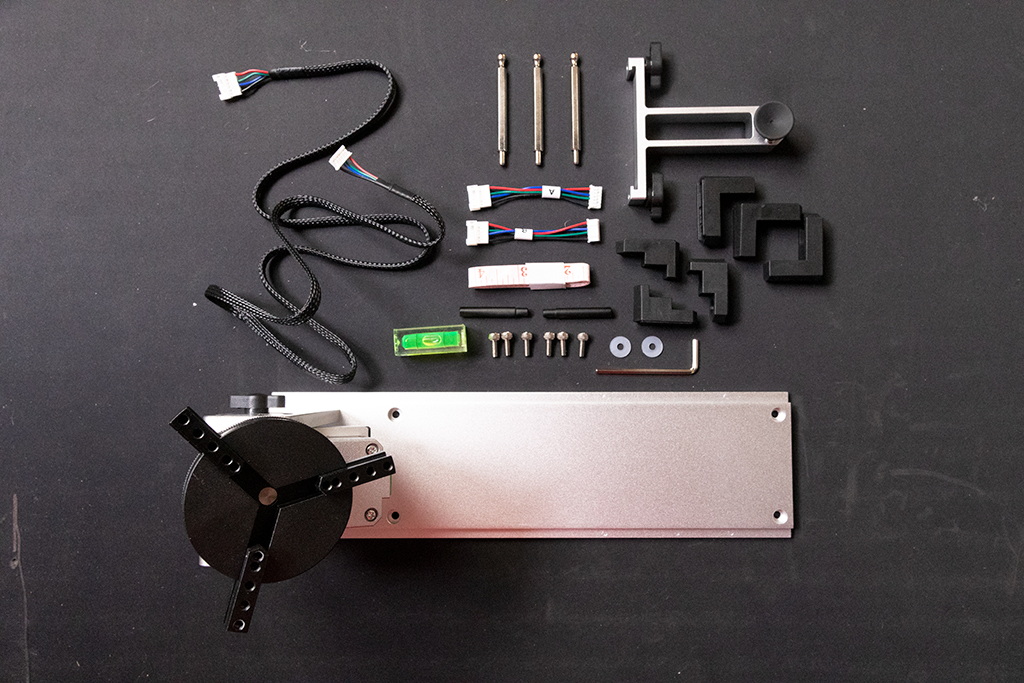

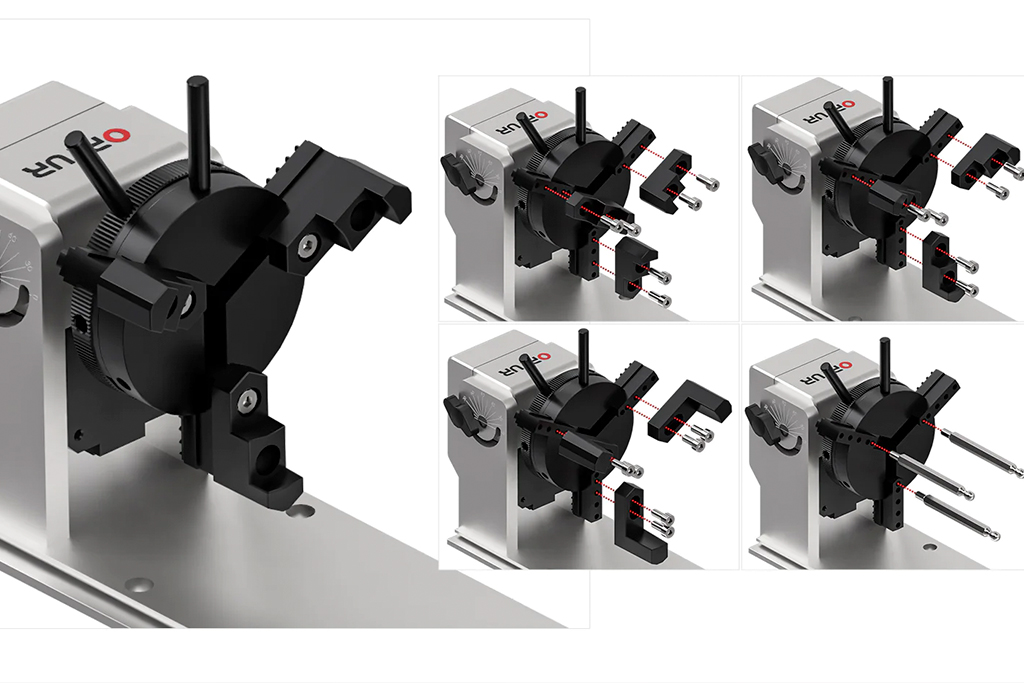

We get quite a lot of accessories in addition to the basic machine. There is a box in which you can find three types of adapters (3 each of our kind), which you will need to hold different objects. We find two small rods, six screws for the adapters, two washers and two wing nuts to facilitate object fixation. Interestingly, there is a tape measure (such as used by tailors, for example), and there is also a spirit level.

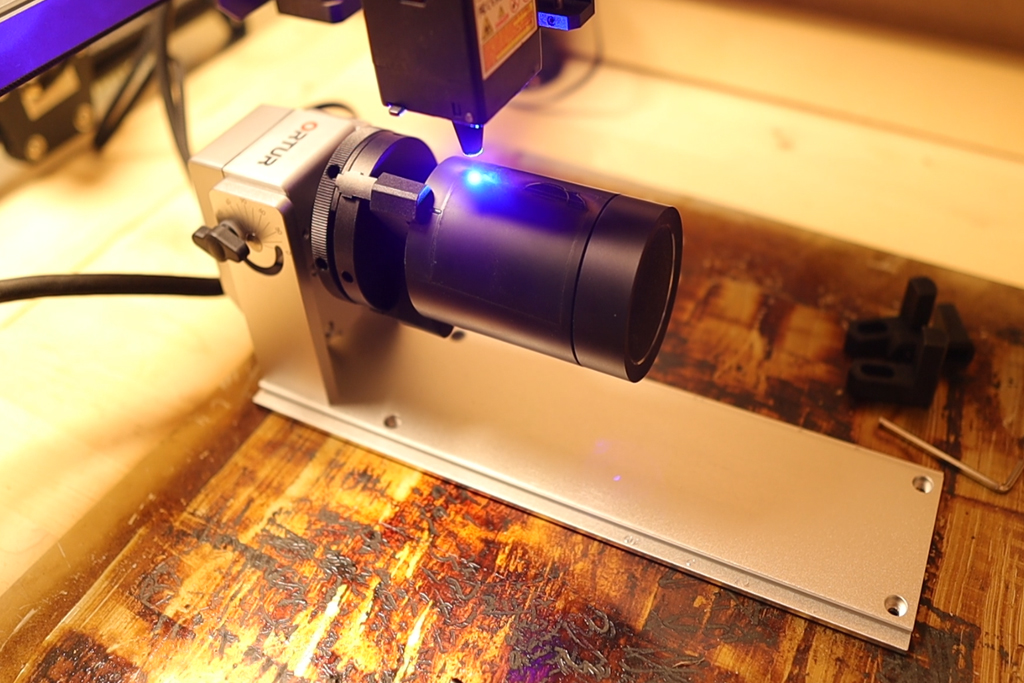

In addition to the things in the small box, there is also a longer cable, which can be used to connect the rotator to the engraving machine, and there are two smaller adapter cables, which allow the connection of several types of machines. And finally, a larger aluminum structure, which is used to fix the opposite side of the objects.

Why do you need a glass spinner?

As engravers, we think in two dimensions by default. We have an X and a Y axis. The laser moves over the workpiece on these axes. If we want to engrave on a cylindrical object, this method is no longer good.

It's not good, because with the laser you always have to set the focus, that is, the point where the light is collected in the smallest possible point. This is where the machine works most efficiently and precisely. The focus can be adjusted by changing the distance between the laser unit and the workpiece.

It is easy to see that this only works if the workpiece is flat, if it is cylindrical, like a glass, then the distance between the surface of the workpiece and the laser will change continuously as it moves along the Y axis.

In other words, you cannot engrave cylindrical bodies without a glass turner!

How does the glass spinner work?

On engraving machines, the laser unit is driven by motors via ribbed belts. These are called stepping motors, and their task is to move the head ultra-precisely with an accuracy of up to hundredths of a millimeter. Carbon brushless motors are used for this, more of course, because you need a motor for the X and Y axes as well.

The operation of the glass spinner is simple. With its use, the movement of the laser unit on the Y axis is stopped, only X remains, and the task of the Y axis motor is taken over by the motor on the glass rotator.

In practice, this looks like the laser head can only move left and right, and the workpiece rotates underneath, replacing the forward and backward movement. With this method, i.e. by rotating the workpiece, it is possible to ensure that the focus of the laser always falls in the right place.

Why is the new Ortur camera good?

Well, the older glass turners worked by having the motor drive two cylinders on them. The cylinders were covered with silicone rubber. The glass or glass could be placed on these cylinders, which rotated the object under the laser.

These are really good solutions, but it can be seen that they only worked properly if the thickness of the object placed on them did not change. Although there was a solution for these, which e.g. the neck of the glass (where the diameter is smaller, of course) could be supported under it, with a little dexterity you could even put a stemmed glass under the laser with this method. But this was also not suitable, because in this case the cup only touched one point of the rubber cylinders, barely a millimeter each, and thus the rotation of the object was not precise enough (the cup slipped during rotation).

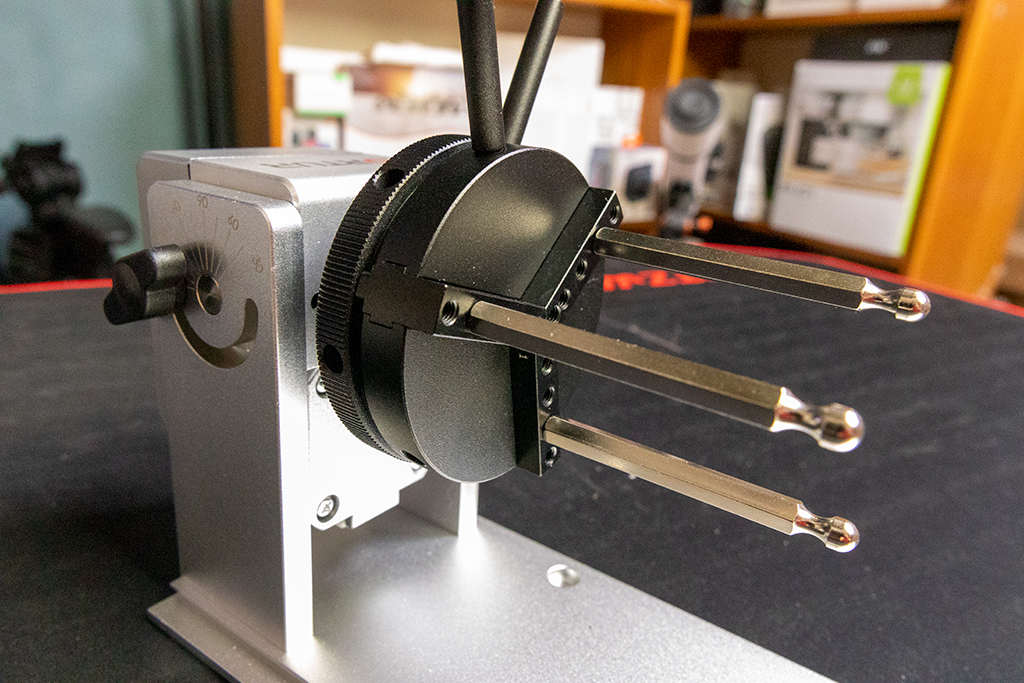

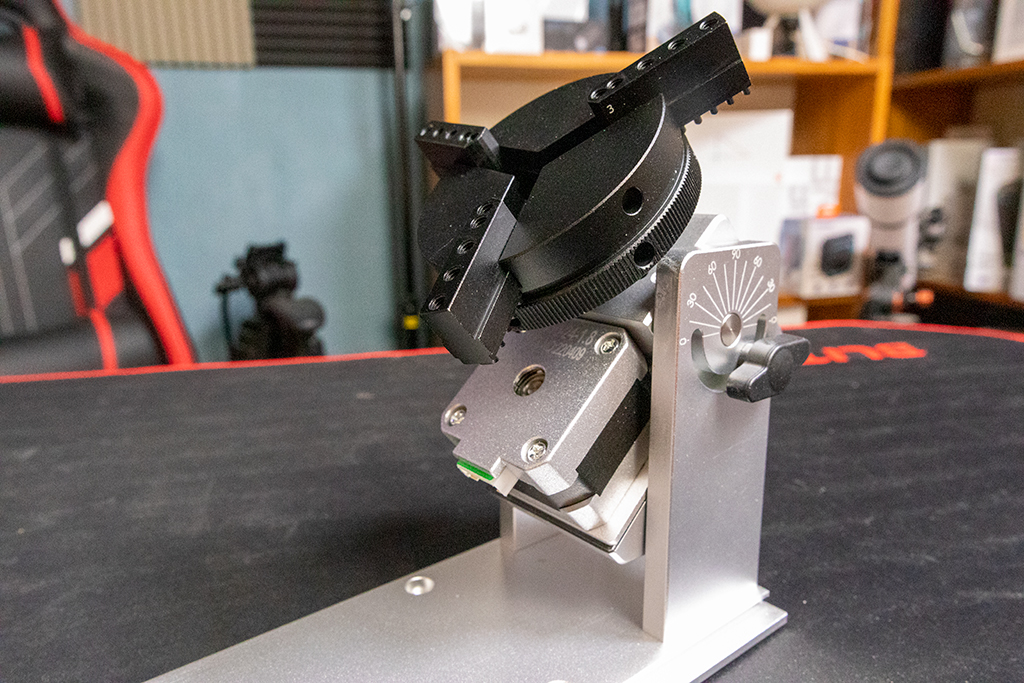

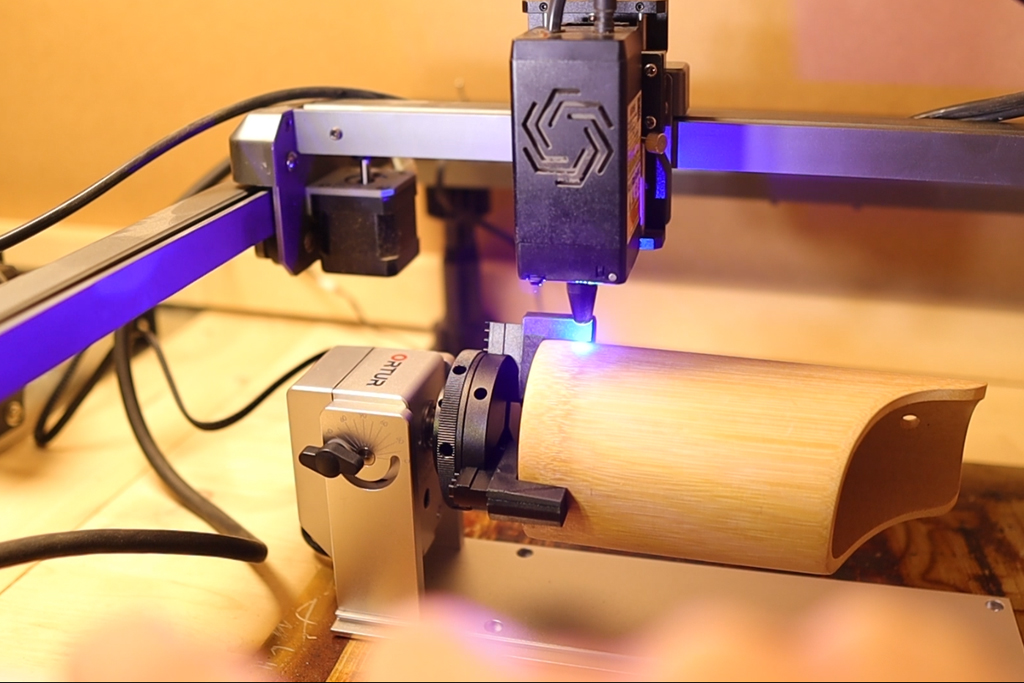

The new Ortur camera, on the other hand, works completely differently. It looks a bit like a mini lathe, and the part for holding objects is like that, only smaller and weaker than a lathe.

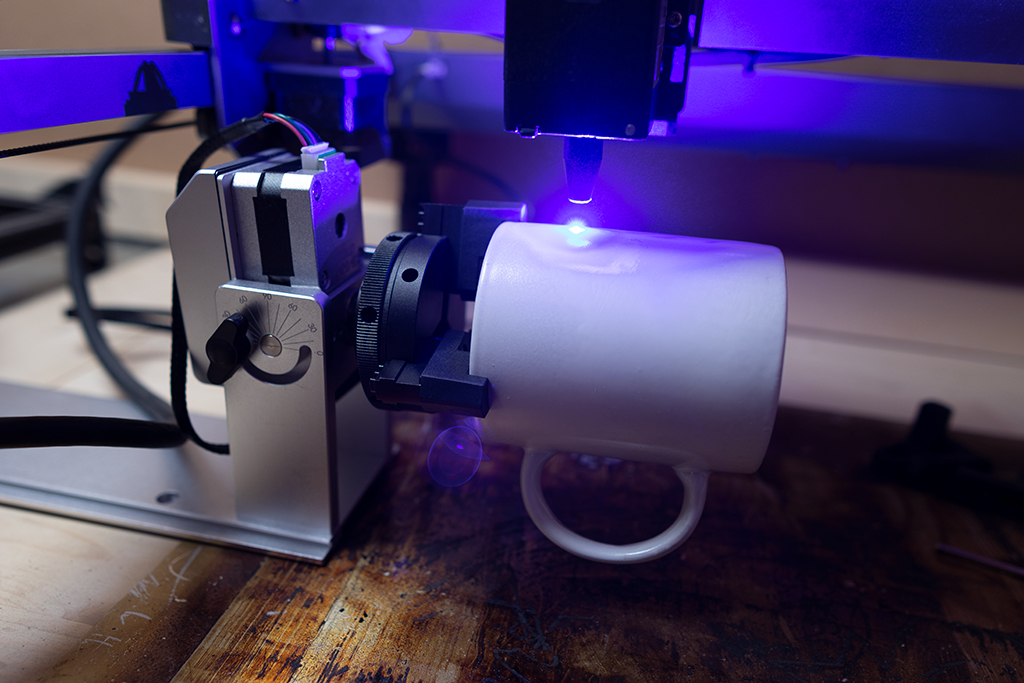

The great advantage of this method is that we can basically pack all kinds of cylindrical things under the laser. It is not a problem if the surface is not straight, if the glass is concave. It is not a problem if the working material becomes a little thinner or thicker, but it is also not a problem if I want to work on, for example, a mug with a handle, since the handle does not get stuck in the rollers, the mug can turn in a circle.

The solution also makes it possible to place longer objects under the machine, i.e. the laser. In other words, the main point is that the new Ortur rotary tool greatly, greatly, greatly broadens the possibilities of use, since we will be able to work on many different workpieces with its help.

How should it be installed?

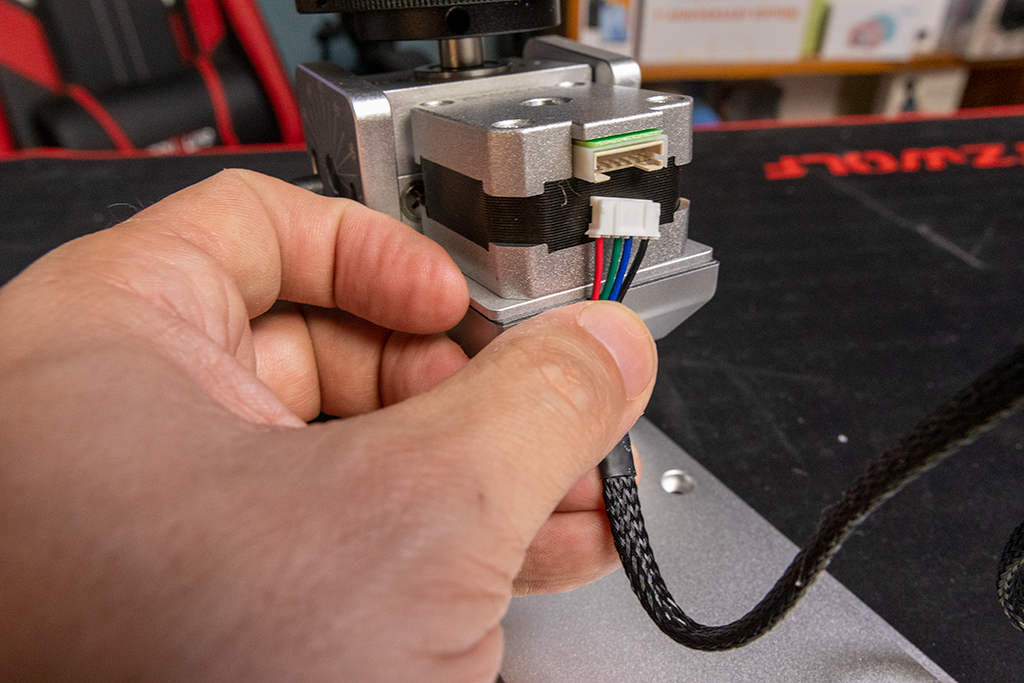

Installation varies depending on the machines used. Obviously, it is easiest to connect to Ortur machines, but this is not the same for all machines.

On older machines, such as any version of the Laser Master 2, the way it works is to disconnect the Y motor cable and connect it to the glass turner. In the case of the Laser Master 3, however, the manufacturer has already simplified the process. There is a separate dedicated connector for the glass turner, this is where the cable should be connected. Then a switch is clicked, and from then on the motor Y of the engraver does not work, but the motor of the glass turner.

You will also need some settings on the software side. I will not describe them in detail now, everything is there in the description attached to the machine, supported by pictures. We receive instructions for the two most frequently used programs, LightBurn and LaserGRBL, for the latter we also need to download a file with which we add extra buttons to the program to manage the camera.

Experiences

In most articles, this is the longest chapter, but it won't be like that here, because I simply have nothing to report. Ortur's filming is perfect. The materials, the installation, the execution, everything is simply perfect. He knows exactly what he promises.

It is easy to use and does not require any major installation or expertise. The software instructions are also clear for both programs.

At the same time, if anyone has any questions or anything is not clear, you can find an 11-minute video on the installation process on Ortur's YouTube page. I would like to note that Ortur is exemplary in this respect as well, because they make very detailed videos about how to replace the control unit in some of their machines.

However, there are a few things that I must draw your attention to!

One is that the first question when installing the extra buttons for the software is whether the old buttons are removed by the installer. If you answer yes, then the corner buttons are deleted, and there is no corner when importing new buttons. So don't let the buttons be deleted, you can delete duplicate buttons one by one afterwards.

Another thing that is very important is that the new rotation buttons must be edited before any work. This is not a mistake, it is simply due to the nature of the work. Because the circumference of the workpieces is not the same, so the radius of the circle is not the same either. The larger the radius, the larger the circumference, the more it moves under the laser per unit movement.

If you do not set the circumference of the workpiece in the button settings, the image you engrave on it will be damaged!

The bottom line is that this should not be forgotten, and thus the enclosed tailor's centimeter, with which we can measure the circumference accurately, immediately makes sense.

The third is to pay attention to where the camera's motor is in relation to the machine. Right or left. In order for the pattern to be engraved not to be reflected onto the workpiece, the motor must be on the right side! If you want it on the left, you have to mirror the pattern in the software.

The fourth point is to always lay out the pattern to be engraved in the software, because that way it will be in the right position on the workpiece!

The fifth is that the direction of the line in graphics should always be horizontal, so the cameraman will slowly rotate the object under the laser. With a vertical setting, the rotation will be fast, the camera may move, and the graphics may be damaged.

That's about it. If you follow these tips, you won't make a big mistake. Of course, you need some experience and routine to adjust the speed of the head and the strength of the laser. Even though I have countless hours of work behind me, the setup does not always succeed the first time. So, if you can, always take care of a test piece so that you don't make a mistake live.

Summary

What can I say, the reason I bought the camera is what it brings. I can engrave irregularly shaped cylindrical objects with it, and with ease.

The price, as usual for Ortur products (not by chance), is quite high, but quality everywhere costs money. I have so much good news that a YRC50 with a coupon code, we now get a $50 discount on it, which means we can get it for $230 instead of $180.

The distributor promises that if the package is caught at customs, the amount paid will be reimbursed to us after presenting the appropriate documents proving the payment.

Here you can buy: