Engraved in stone - the super laser can engrave everything

It is now the most powerful laser for home engraving and cutting.

contents show

Check out the machine in action in our video test!

Introductory

After my previous laser engraving article on YouTube, a reader (viewer) remarked that it didn’t make any sense to laser engrave and cut at home, as there are plenty of companies doing this that make anything to order.

Well, I must admit, He is right, but there is one aspect of the matter that He did not consider. And this is the joy of work and creation, which I never get if I order something from a professional company.

In fact, in order to be part of this joy, you need some determination, you need a lot of money, you need a lot of patience and the desire to experiment, but if you have these, then the universe will expand and you will have super powers like a superhero in the DC universe.

You will be able to create quite amazing things. From ornaments to toys to Christmas tree decorations or special home decor items. And they will all be yours. They are unique, according to your taste, with the work of your hands.

So working at home with the laser requires some patience, you need a hell of a lot of creativity, but I think the joy and pride you get in return that you were able to do this is worth the effort.

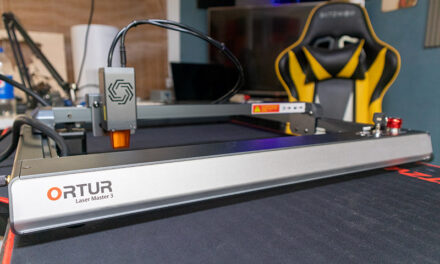

One of the subjects in the test is the Ortur Aufero LU2-10A laser unit

Working at home with the laser is good, but time-consuming. The strength of the laser unit - this is typically given in watts or milliwatts - determines what materials you will be able to work with and how long the job will take.

You don't need to be a mathematician to calculate that if the laser is stronger, cutting through material of unit thickness will go faster even at a higher speed than if you were using a weak laser. The same is true for engraving. If the laser is stronger, engraving a unit surface with a higher carriage speed will give the same result as if you were working with a weak laser at a much lower speed.

The strength of the laser is also important because it determines what materials you will be able to work with. Pine, plywood, hardwood, leather, acrylic are generally available for all machines. But if you were to work with steel or, God forbid, stone, you will surely have problems with the materials.

Well, the Ortur Aufero LU2-10A laser unit is designed to do a nice job - even if possible - with extreme materials.

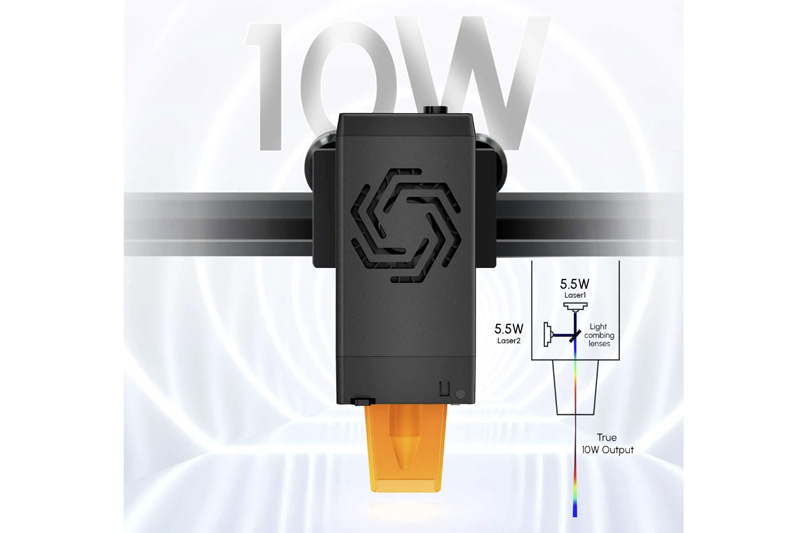

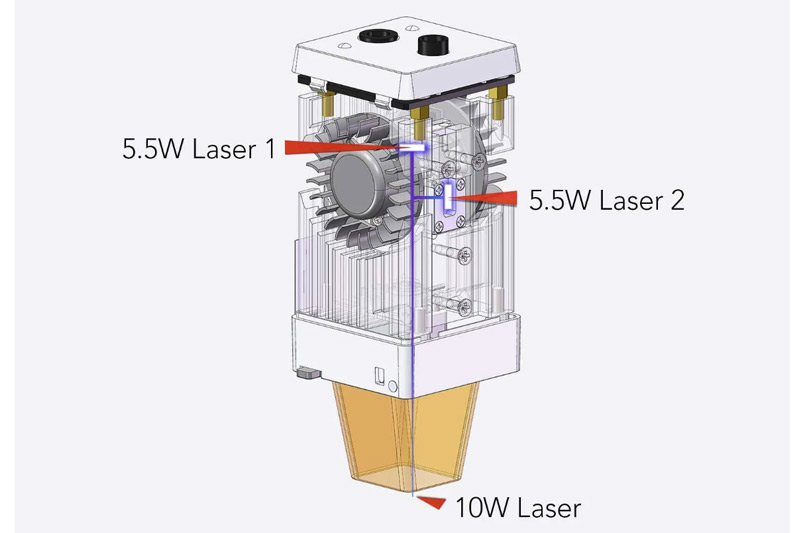

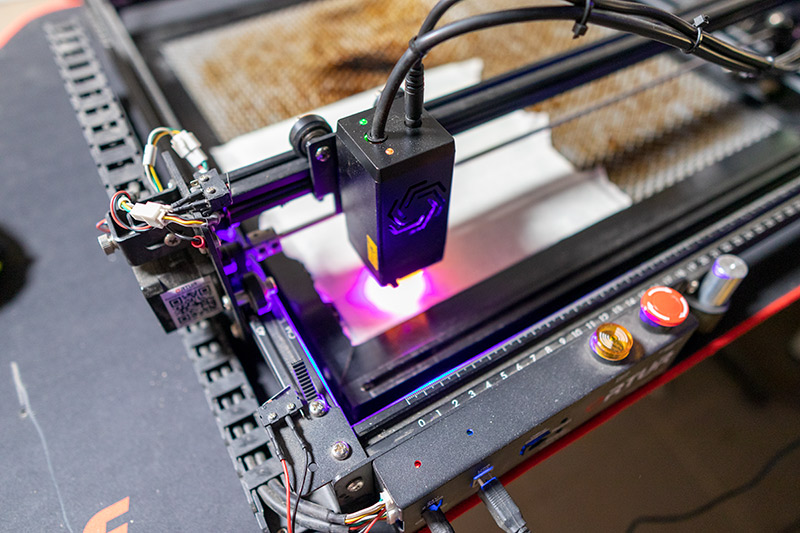

The Ortur Aufero LU2-10A laser unit is a very special piece. The manufacturer has packed not one but two lasers into the standard size unit, and directs their light to the surface to be machined as a beam using a prism (or mirror?) System.

The LU2-4-LF laser unit used in my previous test (https://www.hoc.hu/igy-vagnak-a-profik-lezerrel-otthon/) is 5500 milliwatts, ie 5,5 watts. Well, the subject of today's test, the LU2-10A, incorporates two lasers of this strength, all capable of 10 watts of output power.

Already the previous test was made to show how gorgeous it can be to cut with 5,5 watts, you can think of what a double such powerful laser can do. Amazing things!

According to the manufacturer, it can, for example, cut through a 2-centimeter-thick pine slat. Once again, to make it torquey enough, it can cut through a 2 cm bar! The maximum cutting thickness of acrylic is 3, i.e. THREE centimeters. In addition to traditional softer materials, we can also engrave with it stone and, of course, stainless steel.

In addition, the manufacturer promises to know an unprecedented focus size, meaning it delivers light to the workpiece in a small spot that we haven't seen before. This means a focus of 0,05 x 0,1 millimeters in practice, and even more so in practice, we can “burn” really hair-thin lines into different materials or create an even thinner cutting surface than before.

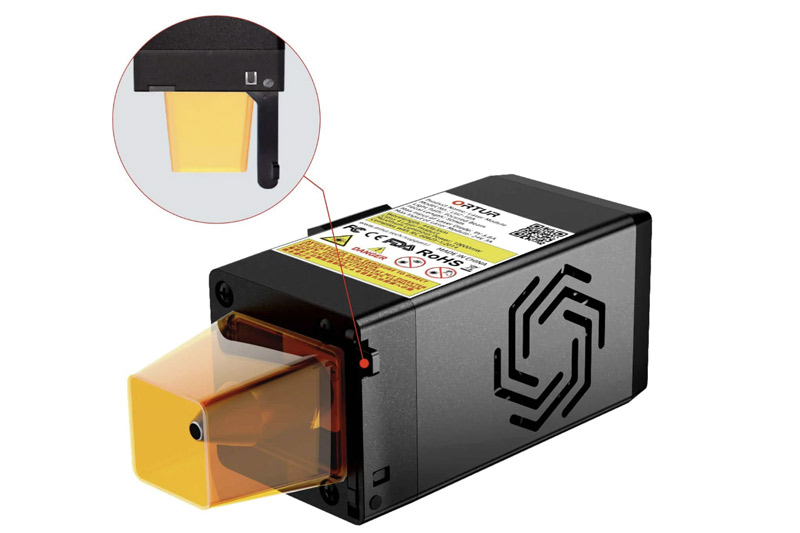

By the end, there are two more interesting things. One is that when using the new head, it is no longer necessary to set the correct distance from the workpiece with an aluminum roller, for which we find a folding arm in the head. This will be the spacer to set the perfect focal length in a second.

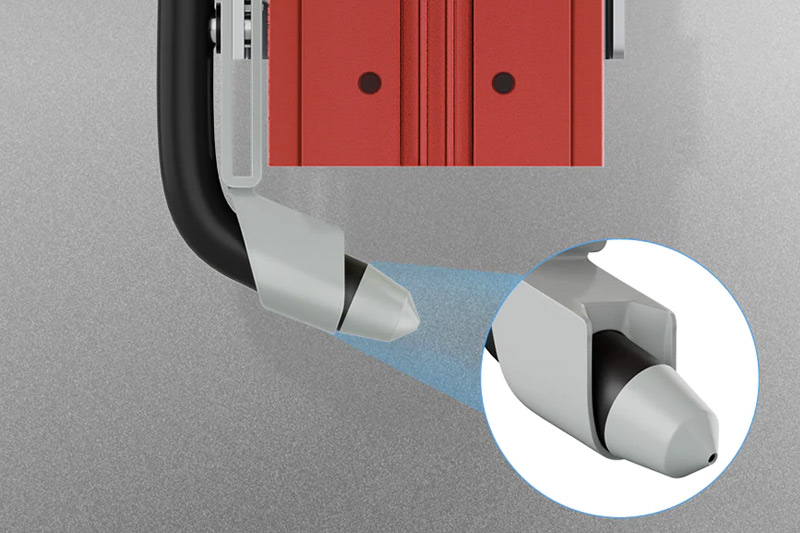

The other, much more important thing for me, is that the Air Assist system was built into the laser unit, which means that we can directly deliver cooling air through the head to the material to be cut and engraved, thus preventing the material from burning.

The second subject of the test: Laser cutting air auxiliary pump

In my previous article, I indicated that I would have to buy something in order for the Air Assist system to work properly. In the test at the time, I used a battery-powered mini compressor, which was not suitable for several reasons. One was that it was constantly drained, the other was that it was unbearably loud.

Fortunately, there are many types of pumps that work relatively quietly and can create even air flow for hours.

As I wrote above, Air Assist is needed so that the upper side of the material, i.e. the side facing the laser, does not burn when cutting, and we get a nice clean, truly professional cut.

Well, I chose a relatively cheap solution that came to me under the brand name DeWallie. I am writing that it came to me under this name, because it is probably an OEM product, so if you find it elsewhere with a different name, at a cheaper price, you can still buy it.

The pump is a simple piece, it has a power inlet on it, a coil with which we can control the amount of air, but it can also be switched on and off, and there is also a small nozzle, to which the rubber tube of the AiR Assist can be connected.

According to the description, the delivered air can be infinitely selected between 0 and 16 liters per minute. At the highest setting, the noise still remains below 60 decibels.

It is important that the package also includes a complete Air Assist system with a rubber band and a nozzle, so it can be installed on laser heads that originally did not have the use of Air Assist.

Practical experience

I’m going to write here primarily about the laser unit because the pump is a really simple piece. It does its job nicely, it is also relatively quiet, but it is not very pleasant to sit next to it for many hours at the highest level. However, when used at a lower gear, I could even work with it, unlike with my small compressor.

The real point in this article is, of course, the laser unit, which, as it turned out above, is a damn strong piece. Of course, this is worth looking at in the home use category, as compared to industrial machines, its performance is also dwarfed.

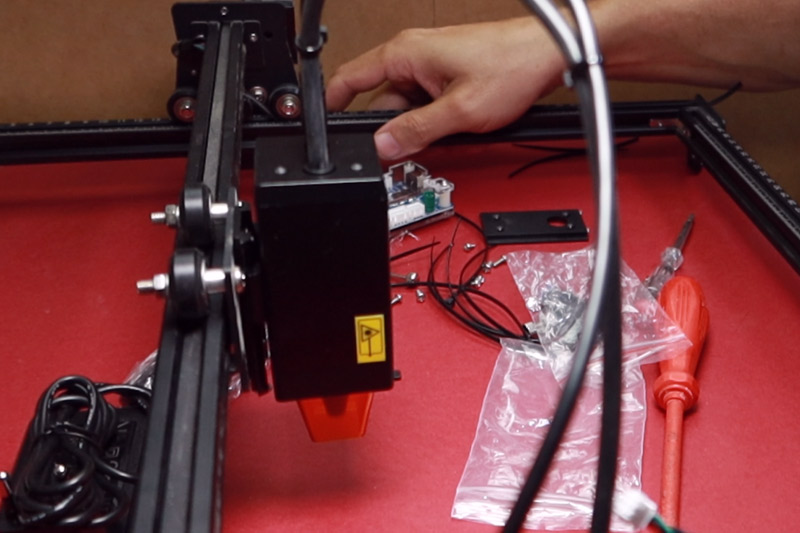

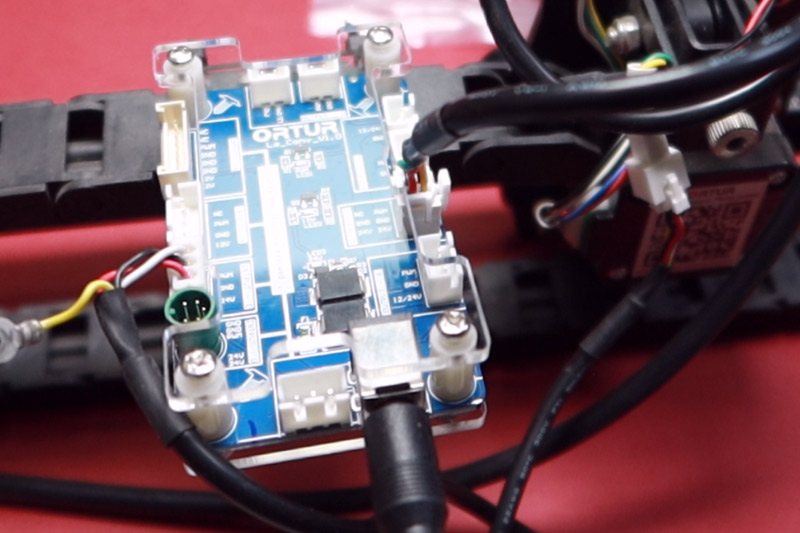

Using the new unit requires some assembly, because the base mounted on the carriage that moves the laser, which holds the unit, is different, and there is also an extra control electronics that can handle the higher power.

So we start the installation by replacing the head that holds the unit on the car. The new base is better than the old one, one fixing screw is enough, and the head doesn't wobble as much. This last advantage comes in handy when setting the focus, it is much easier to set the distance between the laser unit and the material to be processed.

The second step is to install the electronics. The manufacturer recommends this on top of the cable rail, I didn't put it there in the end, because during work everything is on the other side of the machine and the cables were in the way. So the point is to mount it somewhere where it can move with the car.

When you're done, you can feed him and get to work. If you do, you're going to burn your table just the same way I burned it.

There won't be a lot of really important advice in this article, maybe just this one (and one more), but it's very important.

NEVER POWER THE NEW CONTROL ELECTRONICS WHEN THE ENGRAVING MACHINE IS NOT TURNED ON!

So the bottom line: During installation, the cable that was connected from the old electronics to the old laser unit must be plugged into the new controller, and then the new controller must be connected to the new electronics with another cable.

It seemed logical to me that until the new electronics receive a control signal on the old cable, the laser will not turn on. Well, it turns on, and once it turns on, it works. It was lucky that my table was under the machine and not my leg, because the result would have been painful. It was so, but only because of the damage to the table.

So the activation process is as follows:

- You connected the USB and the power supply to the old controller

- You turn on the machine on the old controller

- You give power to the new controller

If you follow this order, you will be fine. I found a simpler solution. I bought a distributor with a switch, plugged the power supply of the old and the new controller into it, and turned everything on together with the switch on the distributor. Let's say that the first thing to do in this case is to connect the computer to the engraver via USB.

And now we are ready, we can start using the machine!

Experiences during use

Needless to say, I tried what I could. I worked with pine raw material, it was a 1,8 inch thick paneled lucca. I worked with 8 millimeter thick plywood, which is a beech raw material. I used stone, it was a 1 inch thick stone used for plinthing. Finally, I also worked with stainless steel. I mean, I tried a lot of things.

First experience, the 2-inch pine slats can really cut through, but not always. Success depends largely on how hard the wood is, how wet the wood is, and how much resin is in it. There was some material that he cut through at first, but mostly it took more threads to make a successful cut. And there was also material I was unable to cut through. So, the 2-centimeter cut doesn't work, you have to experiment with the raw material.

And here comes the second piece of advice, perhaps more important than the first!

NEVER LEAVE THE MACHINE DURING WORK!

Shame or not, it’s a little past that I didn’t set fire to my office. It so happened that I was just working on cutting through the paneled luce when my body said it was time to visit the smallest room in the apartment. I left the machine alone for about 5 minutes while the work material caught fire.

It turned out that there was a larger part filled with resin inside the board, and the resin caught fire. It was perhaps just luck that the board was burning inside, so by the time I got back, only the smoke and the large burnt hole in the material showed that something had gone wrong. The only damage that occurred was that the small plastic cap at the bottom of the laser head, which protects the eyes from the laser light, melted a little. I got away!

What did I do during the test?

Well, such a laser engraving test is longer than anything. It takes a lot more time than any other test, as I have to try a lot of material, look for samples to get as meaningful works into the article as possible.

First I worked with the 8 millimeter plywood. I cut out a world map from it, made a frame behind the plate, glued an RGB LED strip into the frame, and the first wall decoration of my future new office was ready. I think it turned out well. The cuts were sharp and burn-free, although I processed the material at high speed and in several passes.

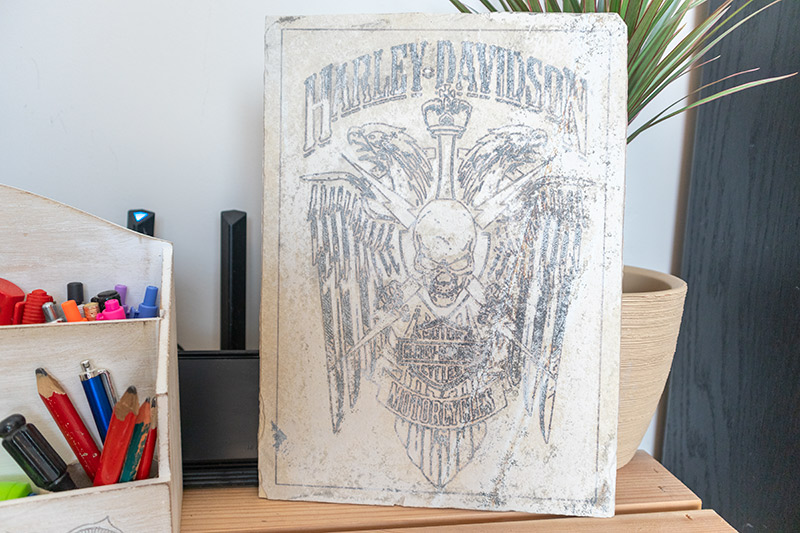

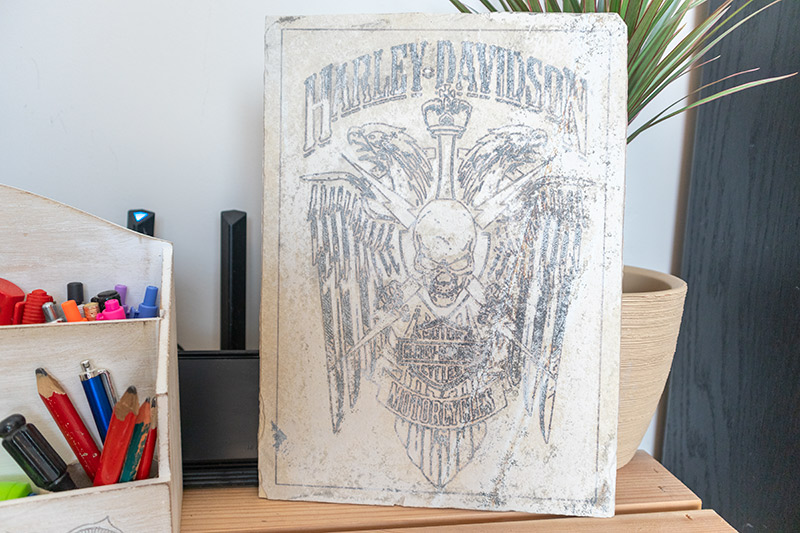

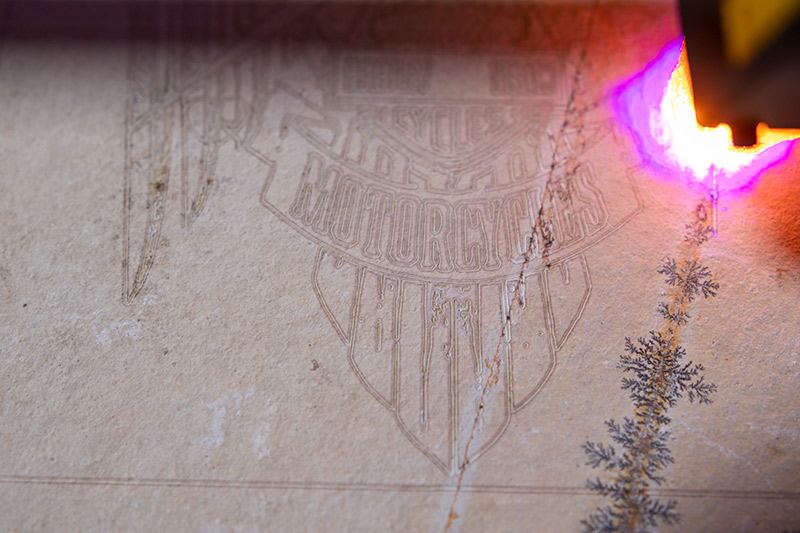

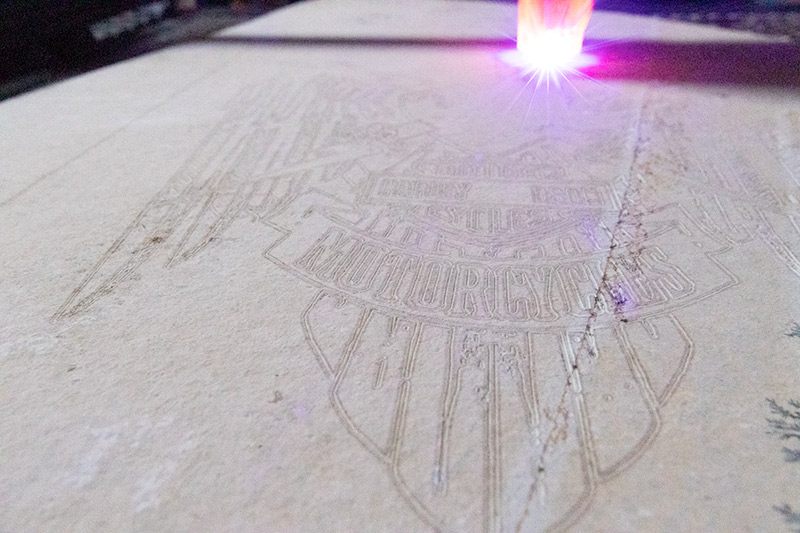

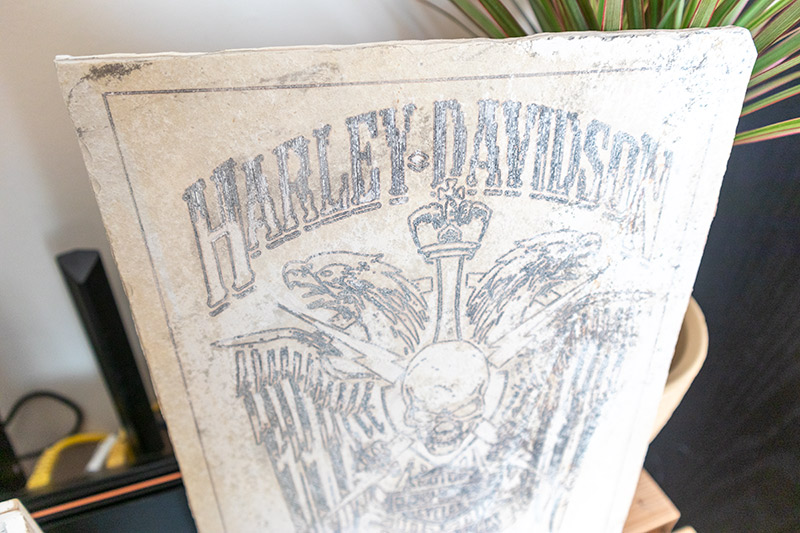

The second was stone. I try to photograph it to see how good it looks, but the images don’t want to give back the effect that the finished work gives live. It became quite plastic, really like a delicate engraving. At the end of the engraving, the stone was given a little black water-based paint, which gave it a good old-fashioned, worn effect.

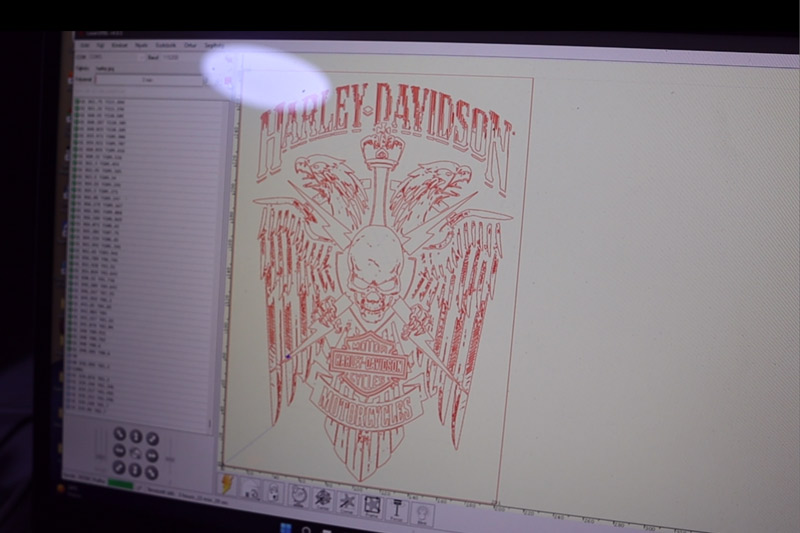

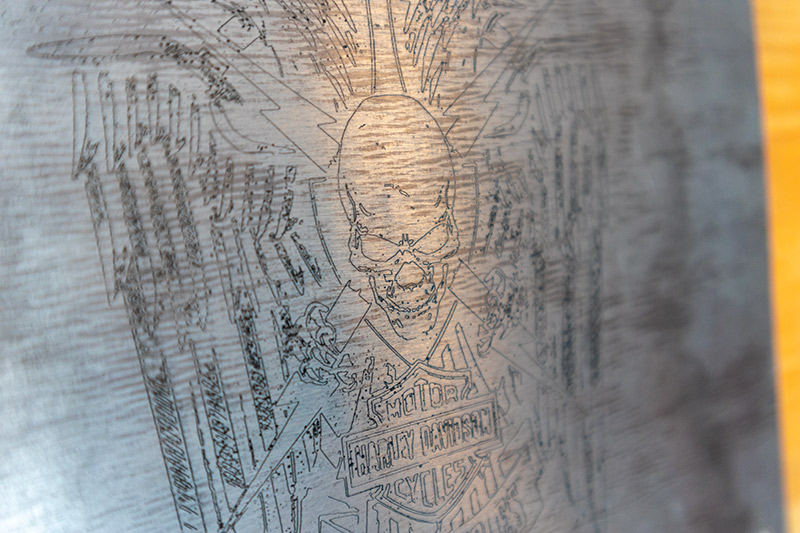

The third was steel. I used the same image here as for the stone. I set the speed of the car to very slow, and the power of the laser to the maximum. I messed around a lot with the focus, because it was more difficult to hit the really good distance on the shiny surface, but in the end I succeeded. And the result is sensational. The laser "drawn" almost hair-thin lines on the steel plate. I will definitely experiment with this, because I will be able to create extremely high-quality things with steel.

At the end came the boarded pine. I engraved, I had already passed the cutting and fire tests, and after a few experiments I decided not to engrave a plain image, but to create a plastic, almost 3D image with a slightly stronger laser. Of course, understand 3D to mean that the final result will be concave, not convex, because I burn the pattern into the wood.

The strength of the laser is shown by the fact that at a speed of 2000, the material was fired to a depth of about 30-60 millimeters with a dynamic laser power of only 2-3 percent. All I can say is that it's impressive!

Summary

Let's start with the pump! Air Assist is a great thing if you cut with a laser, you get previously unimaginable quality, so anyone who breaks their head at laser cutting at home is better off investing in a normal pump. As for the good stuff in the article, it works reliably for the time being, it's not very loud, and it can also be used on machines that don't have Air Assist by default, because we'll find the necessary tubes and nozzles in the package.

So the pump is worth the price!

The LU2-10A laser unit is really brutal, it speeds up the work very much, according to the manufacturer, the speed can be set to 15 millimeters per minute, it splits, you can trust me.

The only downside is that if you retrofit your head with your existing engraver, you will also need to use a second controller due to the higher power requirements. Installing this is not a big deal, but during use, at least when you turn it on, be careful not to burn a hole in your desk.

So, this aftermarket controller is a bit of a fiddly thing, I'll add that I lost less in fiddliness than I gained in performance, so I took it and did well.

And the fact that I can safely touch stone and steel from now on is a huge plus. During the test, after seeing the emblem engraved in the stone, the person I showed it to was very impressed that I was able to make it. I didn't mention it above, but it is important that the stone engraving took place in one go and at quite normal carriage speed, so there was not even a question of having to work with it for days.

So overall, this laser unit is a good choice, and the pump is also a good choice. Unfortunately, they are also being asked for their price, their laser, because it is a device with exceptionally good performance and capabilities, into which the manufacturer immediately packed two lasers. At the moment the price is about 108-109 thousand forints.

The pump is a cheaper item, if you already have a laser engraver at home, it might be worth buying it, especially since everything from the nozzle to the pipes is included in the package. The price is currently around HUF 34.

I have been buying laser stuff from the Made The Best store for a long time, for several reasons. One is that the prices are good and the machines of the leading brands as well as all the accessories available for the machines are available from them. The other is that there is an EU warehouse, but even in the case of a Chinese warehouse order, delivery is fast, and if someone is promised to pay customs, customs clearance, etc., we will get back the costs paid against a receipt sent to the supoort. So it’s like buying from an EU warehouse for a Chinese warehouse as well.

If you are interested in 3D printing or laser engraving and cutting, take a look around them! If you are interested in the products in this article, you can find them here:

Ortur Aufero LU2-10A laser module

Air Assist pump for laser cutting

If you prefer to buy from Amazon, click here: